Magnetic-levitation train suspension fault weight reducing technology emergent processing auxiliary system

A maglev train and emergency treatment technology, applied in electric vehicles, vehicle components, electric traction, etc., can solve problems such as midway damage and support wheel damage, and achieve the effect of reducing wear, reducing pressure, and ensuring normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

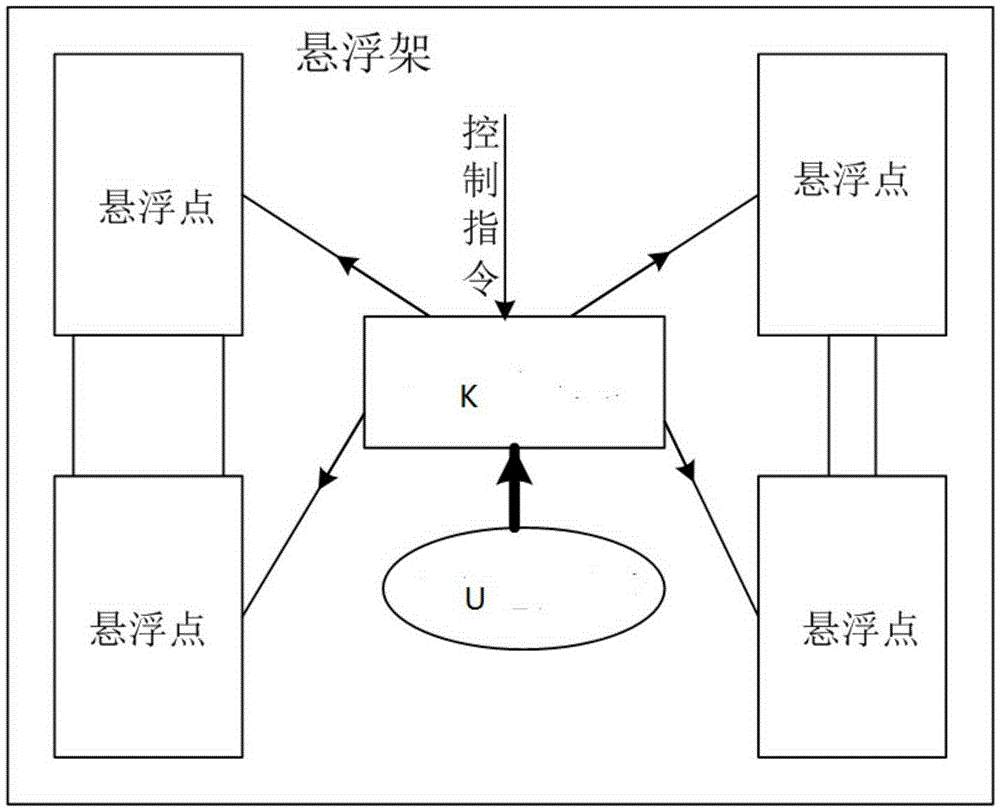

[0026] use figure 1 In a suspension frame, a weight-reducing power supply module and a power switch group connected to the suspension electromagnet are arranged. The suspension frame is 3.2 meters long, self-weight G1=65000N, rated load G2=25000N, supported by four suspension points, and the component force of train gravity offset by a single suspension point is: F1=(G1+G2) / 4=22500N.

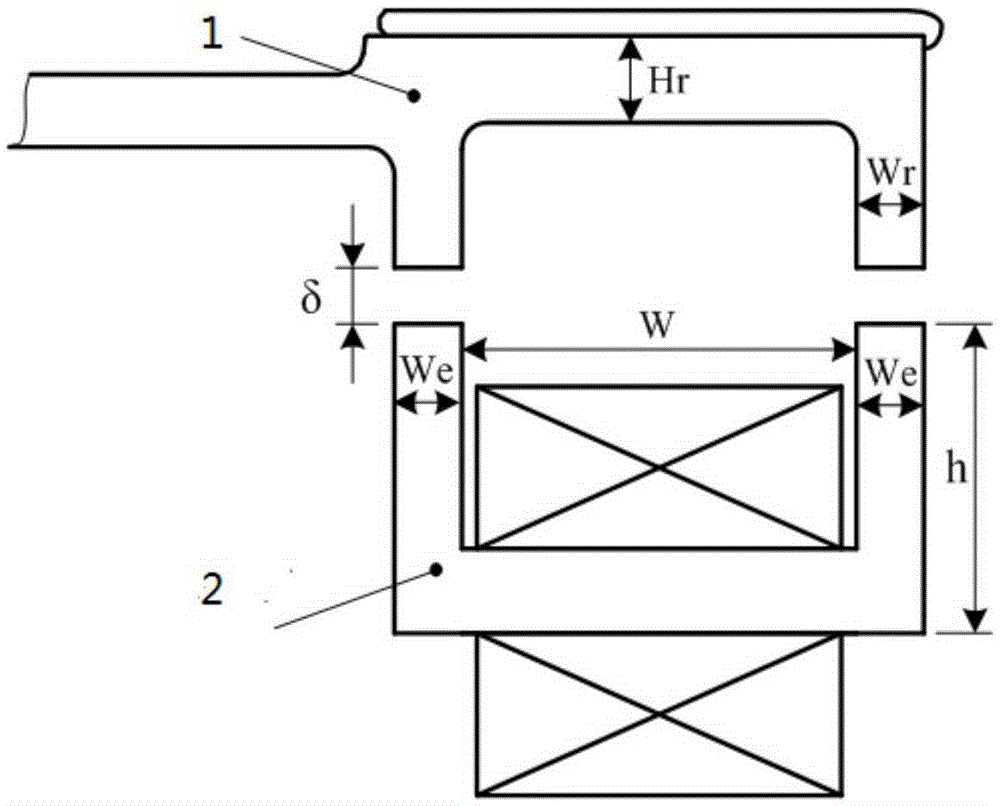

[0027] After the support wheel is laid down, the gap between the suspension electromagnet and the track is δ=8mm. The weight loss power supply is a constant current source, which outputs a constant current of 27A. Such as figure 2 The dimension H and relevant parameters of the levitation electromagnet shown are shown in the table below.

[0028]

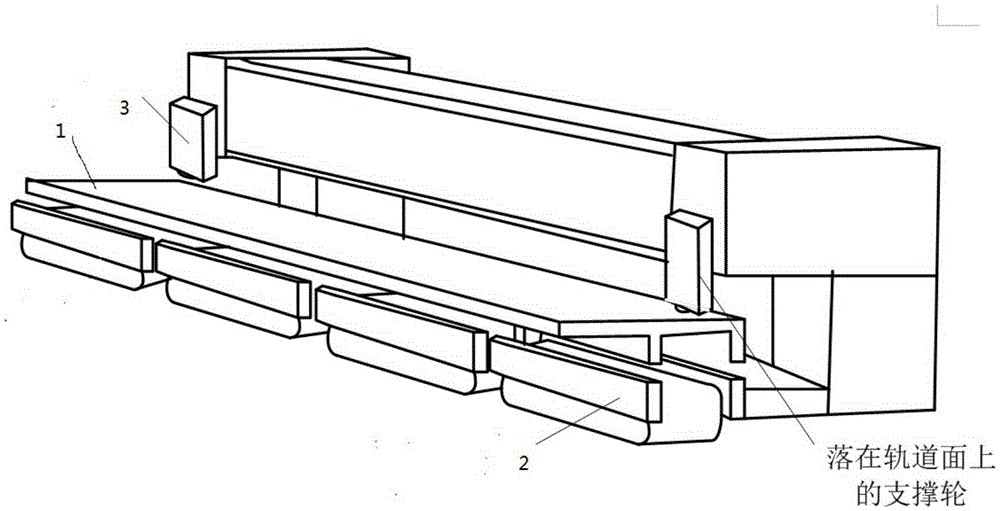

[0029] use image 3 structure, when a certain suspension point of the suspension frame breaks down and cannot be suspended, the corresponding support wheel is laid down at that place. At this time, the pressure between the support wheel and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com