Laminated structure of high-frequency adhesive glue and its preparation method

A stacked structure, high-frequency technology, applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve the problems of low dimensional stability, difficult molding processing, mechanical processing, and inability to manufacture high-density PCBs, etc., to reduce loss, reduce the occurrence of wrong message judgment, and improve the effect of signal transmission quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

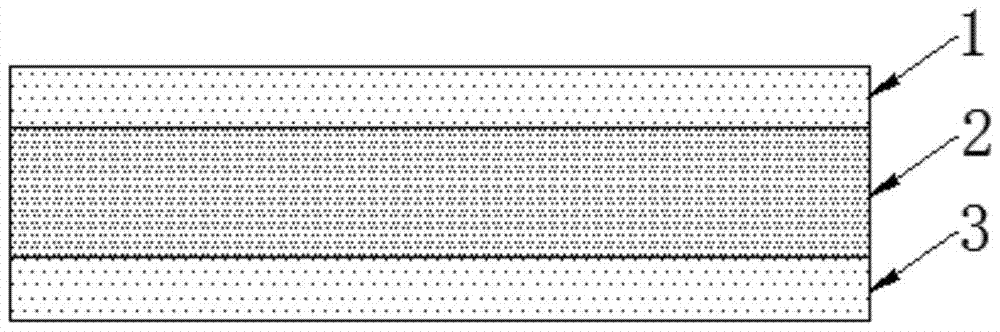

[0028] Embodiment: a high-frequency adhesive glue layered structure, the high-frequency adhesive glue layered structure is composed of a first high-frequency adhesive layer 1, a second high-frequency adhesive layer 2 and a third high-frequency adhesive layer 3, the first high-frequency adhesive layer The materials of the high-frequency adhesive layer, the second high-frequency adhesive layer and the third high-frequency adhesive layer each include a fluorine-based resin and a thermosetting resin;

[0029] Wherein, the proportion of the fluorine-based resin in the first high-frequency adhesive layer is 15-25% (percentage by weight) of the total solid content, and the thickness of the first high-frequency adhesive layer is 2-10 microns;

[0030] Wherein, the proportion of the fluorine-based resin in the second high-frequency adhesive layer is 60-80% (percentage by weight) of the total solid content, and the thickness of the second high-frequency adhesive layer is 10-55 microns; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com