Mine safety monitoring system based on wireless network

A security monitoring and wireless network technology, applied in mining installations, mining equipment, earth-moving drilling, etc., can solve the problems of unreasonable resource allocation of enterprises, difficulty in data sharing, system scalability limitations, etc., to improve data transmission. Performance and efficiency, information sharing, and the effect of facilitating network expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

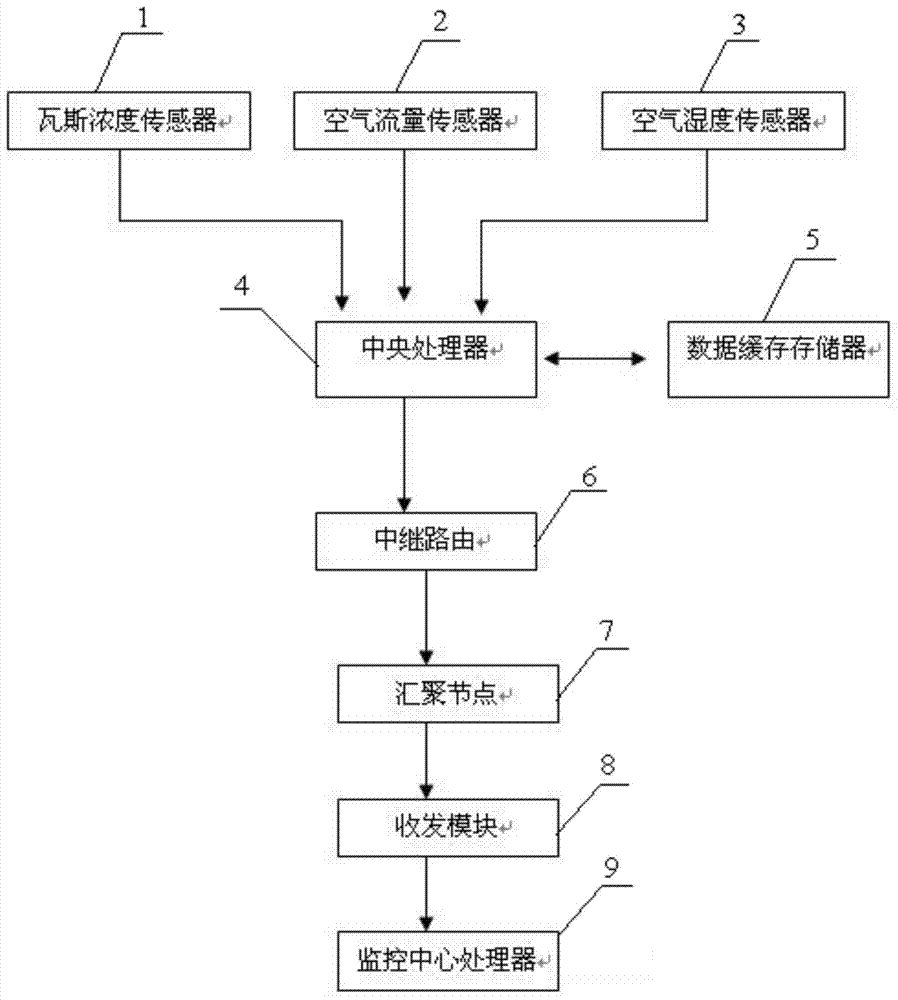

[0025] Such as figure 1 As shown, a wireless network-based mine safety monitoring system includes:

[0026] A gas concentration sensor 1, used to collect the gas concentration in the mine, the output end of the gas concentration sensor 1 is connected to the in-well gas concentration input end of the central processing unit 4;

[0027] An air flow sensor 2 is used to collect the air flow in the mine, and the output end of the air flow sensor 2 is connected with the air flow input end in the well of the central processing unit 4;

[0028] An air humidity sensor 3 is used to collect the air humidity in the mine, and the output end of the air humidity sensor 3 is connected with the air humidity input end in the well of the central processing unit 4;

[0029] A wireless network communication system, the wireless network communication system includes a relay route 6, a convergence node 7 and a transceiver module 8, the data signal output end of the central processing unit 4 is conn...

Embodiment 2

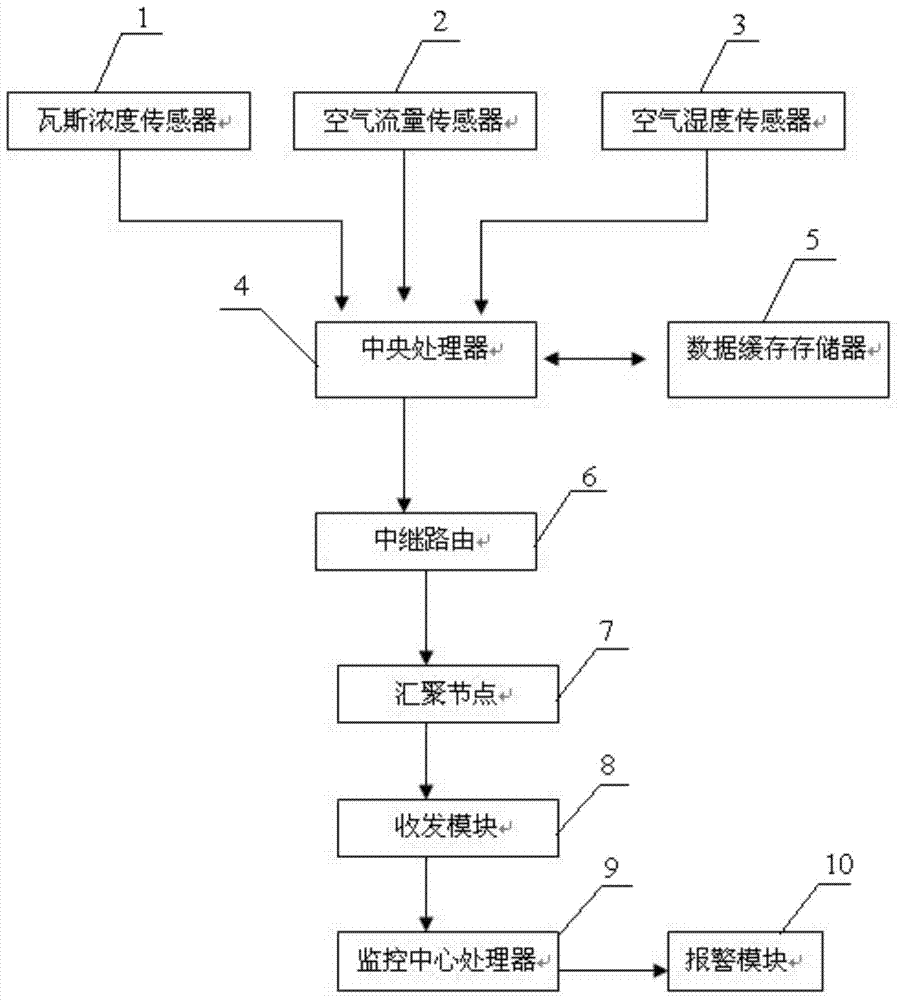

[0034] Such as figure 2 As shown, a wireless network-based mine safety monitoring system includes:

[0035] A gas concentration sensor 1, used to collect the gas concentration in the mine, the output end of the gas concentration sensor 1 is connected to the in-well gas concentration input end of the central processing unit 4;

[0036] An air flow sensor 2 is used to collect the air flow in the mine, and the output end of the air flow sensor 2 is connected with the air flow input end in the well of the central processing unit 4;

[0037] An air humidity sensor 3 is used to collect the air humidity in the mine, and the output end of the air humidity sensor 3 is connected with the air humidity input end in the well of the central processing unit 4;

[0038] A wireless network communication system, the wireless network communication system includes a relay route 6, a convergence node 7 and a transceiver module 8, the data signal output end of the central processing unit 4 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com