Heat treatment setting method for high-strength elastic material coil spring

An elastic material and high-strength technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve problems such as deformation gaps and unevenness, achieve deformation stress release, uniform distribution, and ensure dimensional stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the specific implementation process, the heat treatment and shaping method of the high-strength elastic material coil spring of the present invention, the specific steps are as follows:

[0019] 1. Shaping fixture design

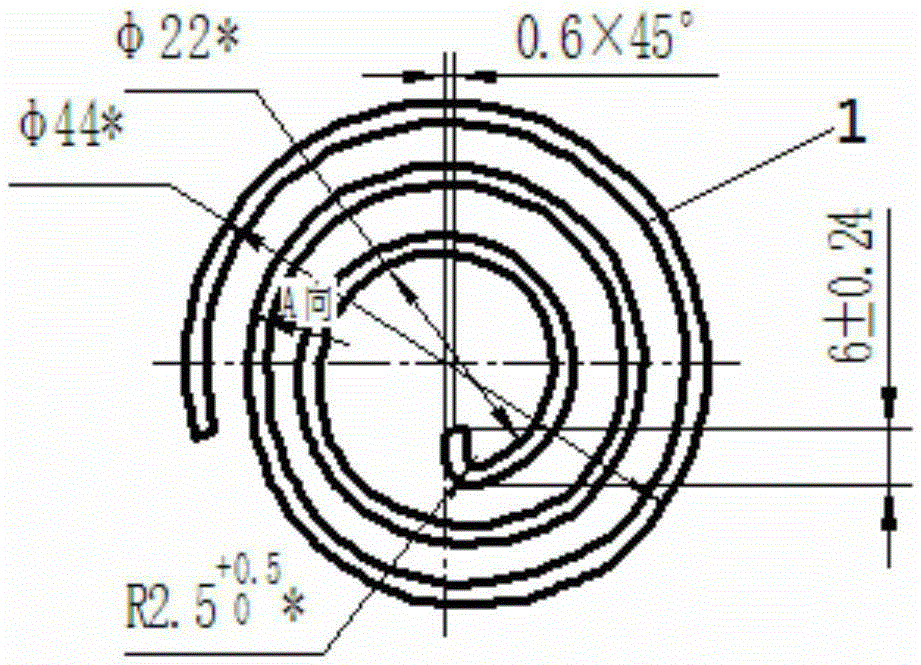

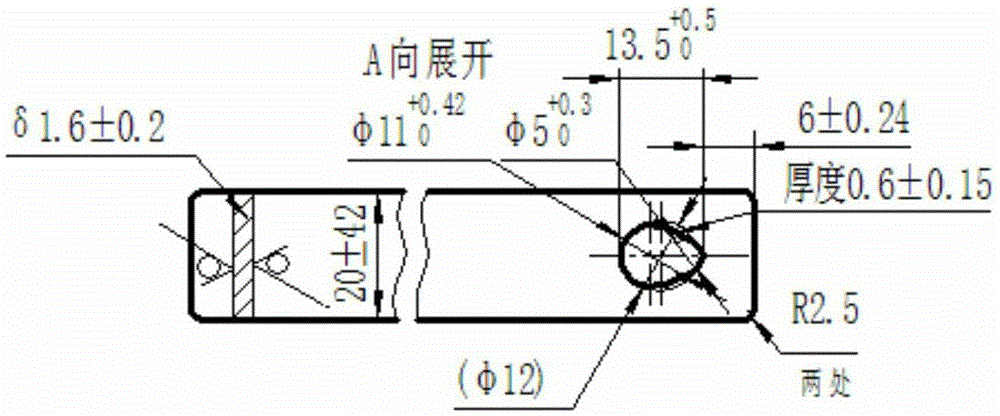

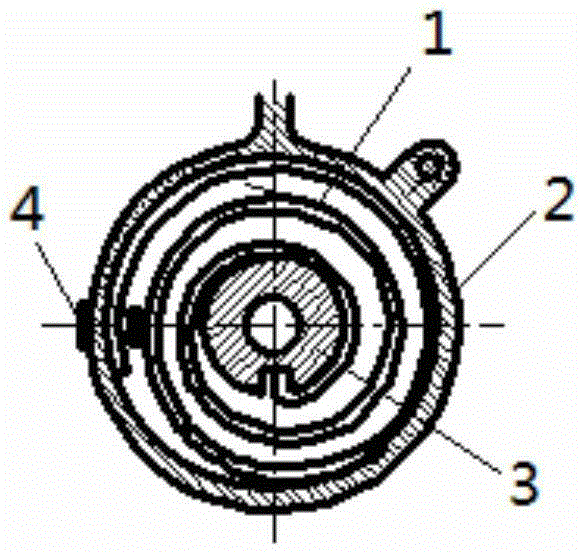

[0020] Such as Figure 2(a)-Figure 2(b) As shown, according to the structural characteristics of the coil spring parts, the shaping fixture is designed to fix the structure of the jacket. After the coil spring parts are loaded, pins of different sizes are placed in the gaps of the coil spring parts to ensure the shape of the coil spring parts.

[0021] 2. The principle of heat treatment and shaping

[0022] After winding according to the requirements of the design drawing, it is necessary to carry out heat treatment for shaping and aging. This is the key process of forming the coil spring. Due to the special shape of the coil spring, it is different from the general clockwork spring. The shape of the general clockwork spring is an Archimedes spira...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com