High-strength weft insertion-warp knitting base cloth

A high-strength, base fabric technology, applied in warp knitting, textiles, papermaking, knitting, etc., can solve the problems of high production cost, high cost, lack of protection, etc., to achieve high market competitiveness, low production cost, The effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

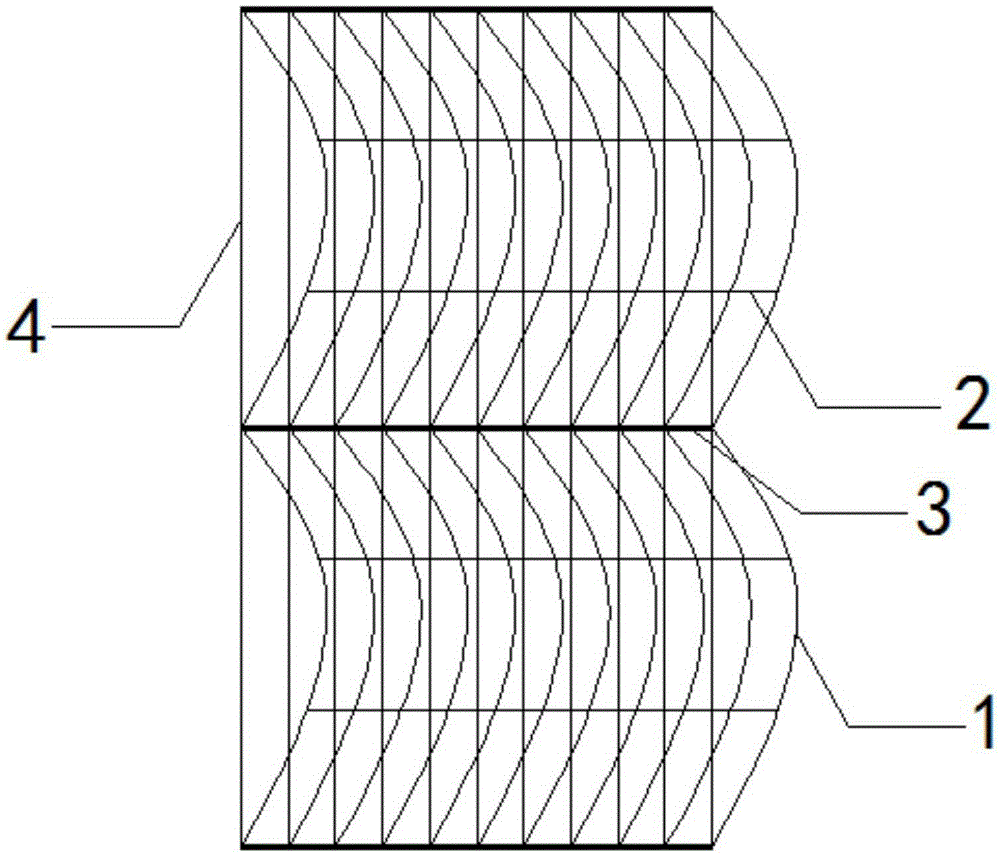

[0013] refer to figure 1 , a kind of high-strength weft-inserted warp-knitted base cloth of the present invention comprises carbon fiber, polyethylene terephthalate fiber, polytrimethylene terephthalate fiber, and the density of described carbon fiber is higher than 1.5g / cm 3 , the 86dtex / 30F carbon fiber and 44dtex / 10F polyethylene terephthalate fiber are intertwined to form a warp 1, the carbon fiber is wrapped in the polyethylene terephthalate fiber, and the 44dtex / 70F polyethylene terephthalate fiber The ethylene glycol diformate fibers are intertwined to form a weft yarn one 2, the 86dtex / 50F carbon fiber and the 44dtex / 20F polyethylene terephthalate fiber are intertwined to form a weft yarn two 3, and the two adjacent weft yarns two The 3 rooms contain two weft yarns one 2, and the 48dtex / 70F polytrimethylene terephthalate fibers are intertwined to form a missing line 4, and the missing line 4 is connected with the warp yarn 1 and the weft yarn 2 every two weft yarns 1 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com