Washing machine heater with flow diversion heating plates

A heating plate and heater technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problem of difficulty in meeting the requirements of uniformity, and achieve the effects of increasing the diversion, improving the uniformity and improving the heating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

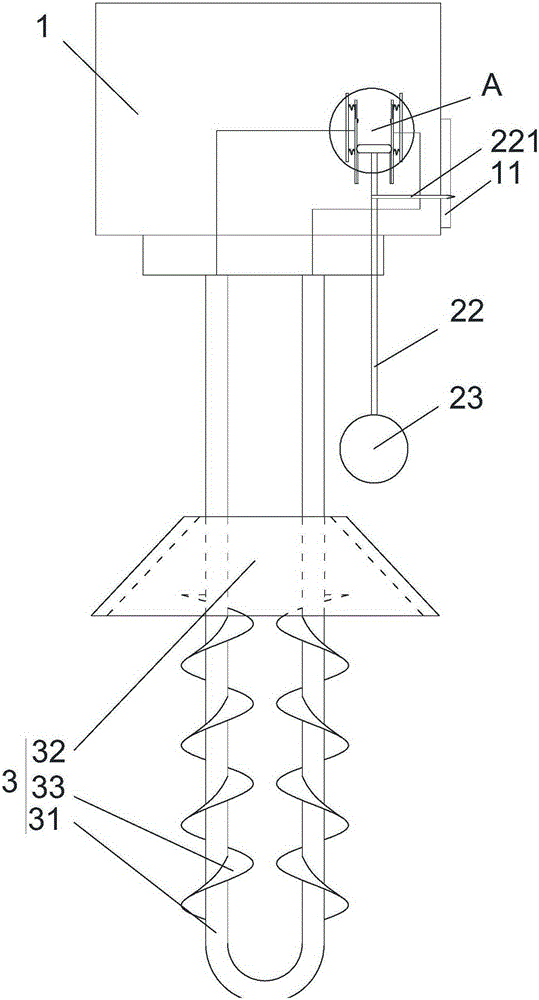

[0018] refer to figure 1 and figure 2 As shown, a washing machine heater with a guide heating sheet proposed by the present invention includes a mounting frame 1 , a safety water level control mechanism 2 and a heating mechanism 3 .

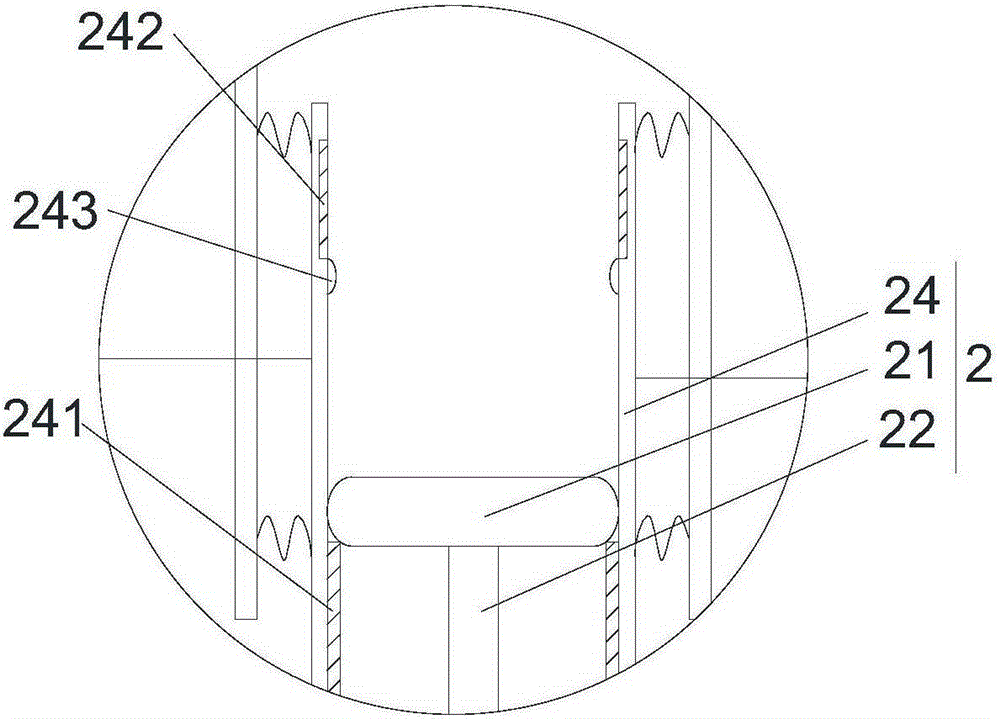

[0019] The safety water level control mechanism 2 includes a conductive block 21, a floating rod 22, a floating ball 23 and two conductive plates 24. The conductive block 21 is movably installed in the mounting frame 1. The conductive block 21 can move vertically, and the floating rod 22 is installed Below the conductive block 21, the floating ball 23 is installed below the floating rod 22, and the two conductive plates 24 are vertically installed in the mounting frame 1 through elastic members. A conductive channel is formed between the two conductive plates 24, and the floating ball 23 passes through the floating rod. 22 Drive the conductive block 21 to move inside and outside the conductive channel. When the conductive block 21 is in the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com