Manufacturing method of glass fiber reinforced plastic composite traffic sign

A composite material and production method technology, applied in road signs, traffic signals, chemical instruments and methods, etc., can solve the problems of large consumption of aluminum alloy materials, high recycling value, high price, etc., and achieve cost reduction and excellent anti-aging performance. , the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

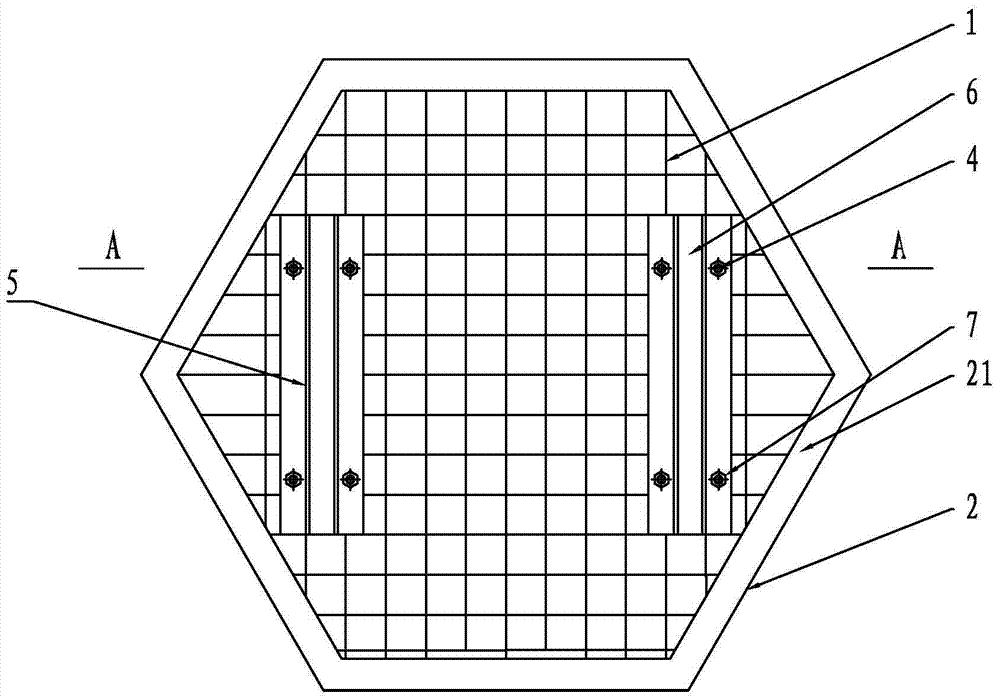

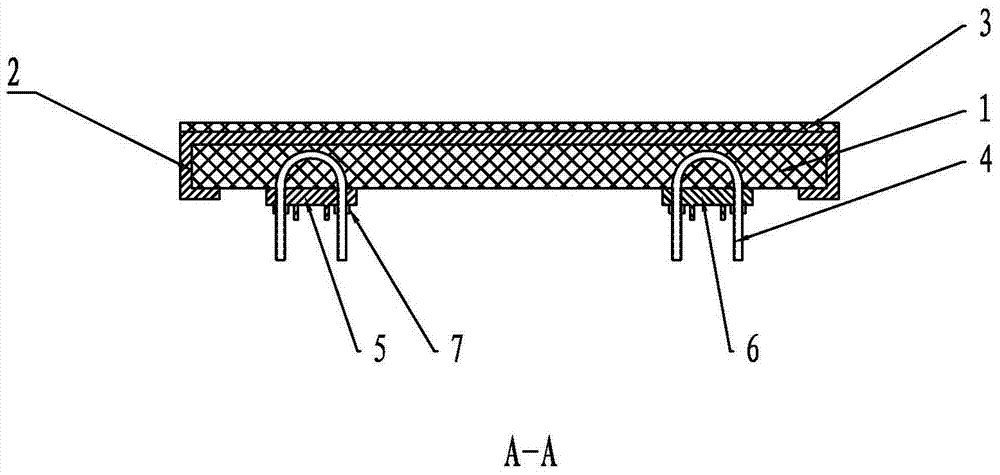

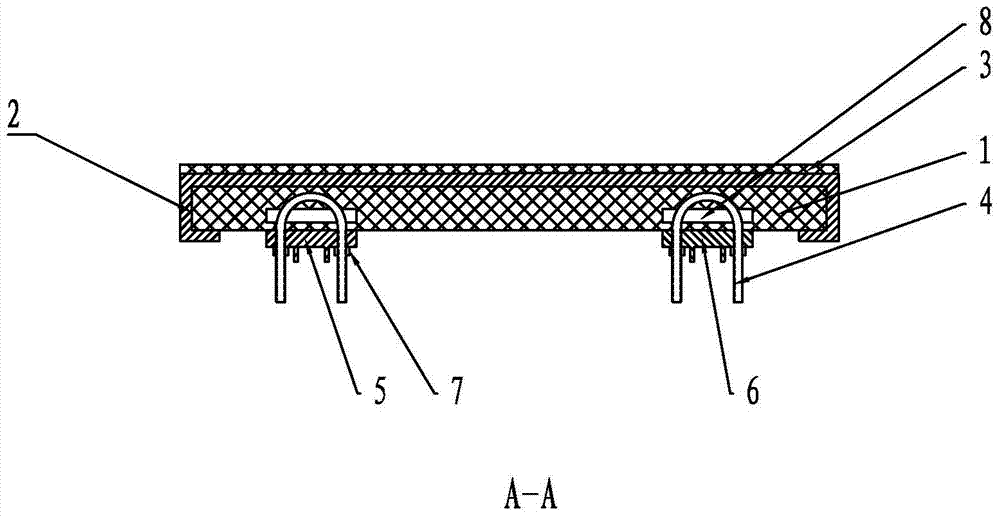

[0025] Use large molds to make FRP grid panels, and determine the number of embedded U-bolts according to the molding size, pre-embed U-shaped bolts in the FRP grid panels according to the required number, and cut the finished FRP grid panels to the required size The regular hexagon, using a punching machine to process the metal plate into a shape that matches the FRP grid plate, mix the epoxy resin glue and polyamide resin evenly at a mass ratio of 1:1, and then combine the FRP grid plate and the metal plate Paste them together so that the metal plate is covered on the front surface and side of the FRP grid plate and form an edge on the back, pressurize with a press, and the pressure is controlled at about 0.6MPa, and then cured at room temperature for 2 hours. The first and second slots are respectively installed on the U-shaped bolts and fastened by nuts to obtain the FRP composite traffic signboard of the present invention, whose main properties are shown in Table 1.

Embodiment 2

[0027] Use a mold that matches the required FRP grid plate to make the FRP grid plate. A pair of iron plates and a pair of U-shaped bolts are embedded in the left and right sides of the FRP grid plate, and the metal plate is processed by a punching machine. To match the shape of the FRP grid plate, mix epoxy resin glue and T31 epoxy resin curing agent evenly at a mass ratio of 1:0.1, and then paste the FRP grid plate and the metal plate together so that the metal plate is covered The front surface, sides and back of the FRP grid plate are bounded, pressurized with a press, the pressure is controlled at about 4.9MPa, and then cured at room temperature for 1 hour, and the first and second slots are respectively installed on the On the U-shaped bolts and fastened by nuts, the FRP composite traffic signboard of the present invention is obtained, and its main properties are shown in Table 1.

[0028] The main properties of the FRP composite traffic sign board that the above-mention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com