Excavation construction method of assembled reinforced scarifier for plateau permafrost region

A construction method and ripper technology, applied to earth movers/shovels, construction, etc., can solve the problems of difficult quality assurance, high construction difficulty, high construction cost, etc., achieve high work efficiency, save input, and reduce air pollution pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

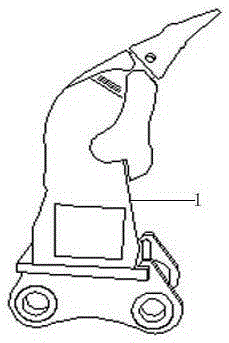

[0033] The excavation construction method of the assembled reinforced ripper in the plateau permafrost area of the present invention is characterized in that the assembled reinforced ripper is assembled on the crawler excavator, which can be exchanged and used with the bucket, and the hydraulic pressure of the crawler excavator is utilized. The piston pushes the tooth seat of the ripper to change the excavation direction and operating point of the bucket hook of the ripper. The bucket hook 1 of the described ripper is in the shape of a single-tooth front end with a pointed mouth.

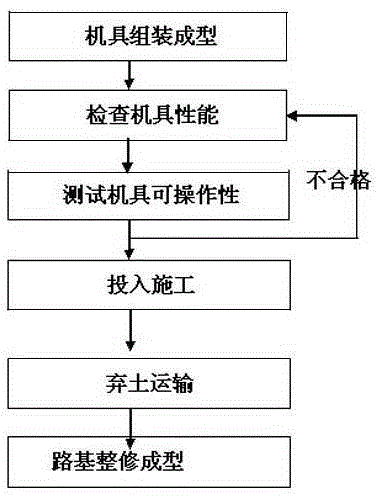

[0034] The excavation construction method of the assembled reinforced ripper in the permafrost region of the plateau is characterized in that the steps of the method are:

[0035] (1) The tool is assembled and formed; the choice of scarifier model should be in accordance with Choose the maximum power of the excavator and the weight of the adapted machine;

[0036] (2) Check the performance of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com