Method for connecting prefabricated floor and prefabricated vertical component

A technology of vertical components and connection methods, which is applied to floors, building components, building structures, etc., can solve the problems of inability to achieve integral prefabrication of walls and floors, low prefabrication assembly rate, and multiple on-site wet operations, so as to improve prefabrication The assembly rate, the mechanical performance of the floor are excellent, and the effect of reducing the length of the shelving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

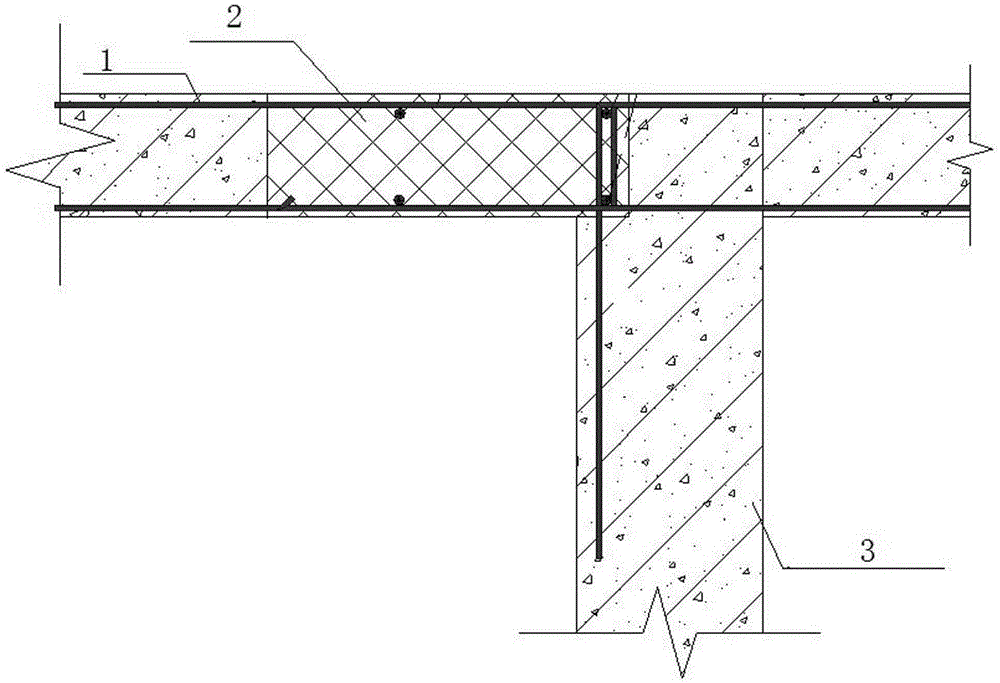

[0015] See figure 1 , a method for connecting a prefabricated floor slab and a prefabricated vertical member, the feature of the present invention is that the steps are:

[0016] 1) The connection between the prefabricated floor slab and the prefabricated vertical member of the concrete cast-in-place slab; wherein, the concrete cast-in-place slab is set at the junction of the prefabricated floor slab and the prefabricated vertical member, and the connecting end surface of the prefabricated floor slab is provided with a rough surface or a toothed surface; The upper and lower steel bars on the prefabricated floor form a closed loop and extend into the post-casting belt, and the prefabricated vertical member protrudes from a corner of the circular steel bar. The two kinds of steel bars form a new closed loop (the position of the closed loop is on the prefabricated vertical component), and the closed loop is inserted longitudinal reinforcement;

[0017] 2) The concrete cast-in-pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com