Light assembly type stairway and construction method thereof

A construction method and prefabricated technology, applied to stairs, ladder-like structures, buildings, etc., can solve problems such as difficult installation, high mechanical requirements, and unfavorable earthquake resistance, so as to improve construction efficiency, good shear resistance performance, and benefit The effect of safety management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

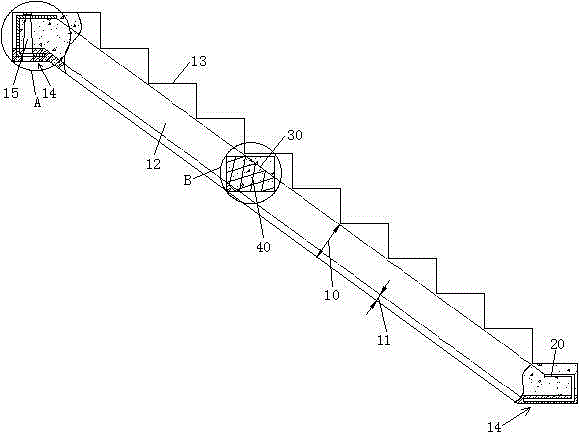

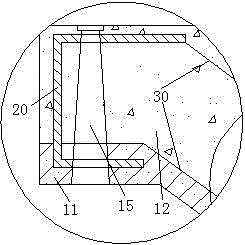

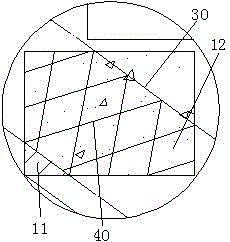

[0030] refer to Figure 1 to Figure 3

[0031] A lightweight assembled staircase, comprising a slanted beam 10 with a lightweight concrete layer 12 on the upper floor, a number of steps 13 are provided on the upper slope of the slanted beam, and the upper and lower ends of the slanted beam are respectively provided with lap joints. The supporting part 14 is respectively wrapped with thin-walled U-shaped steel 20, the notches of the two thin-walled U-shaped steels face each other, and the upper and lower parts of the two thin-walled U-shaped steels are respectively connected by electric-welded steel mesh 30 wrapped in the inclined beam , there are obliquely inserted steel wires 40 welded between the two electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com