Semiconductors lamp

A semiconductor and substrate technology, applied in the field of retrofit lamps with form factors, can solve the problems of limited casting materials and components, expensive casting materials and/or components, and high cost, and achieve simple and compact layout. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

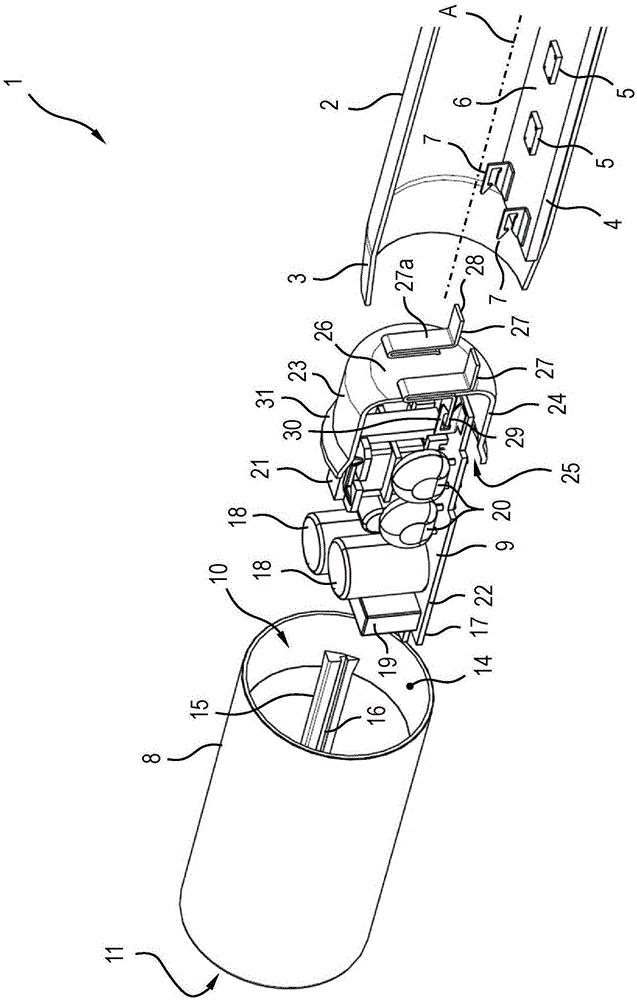

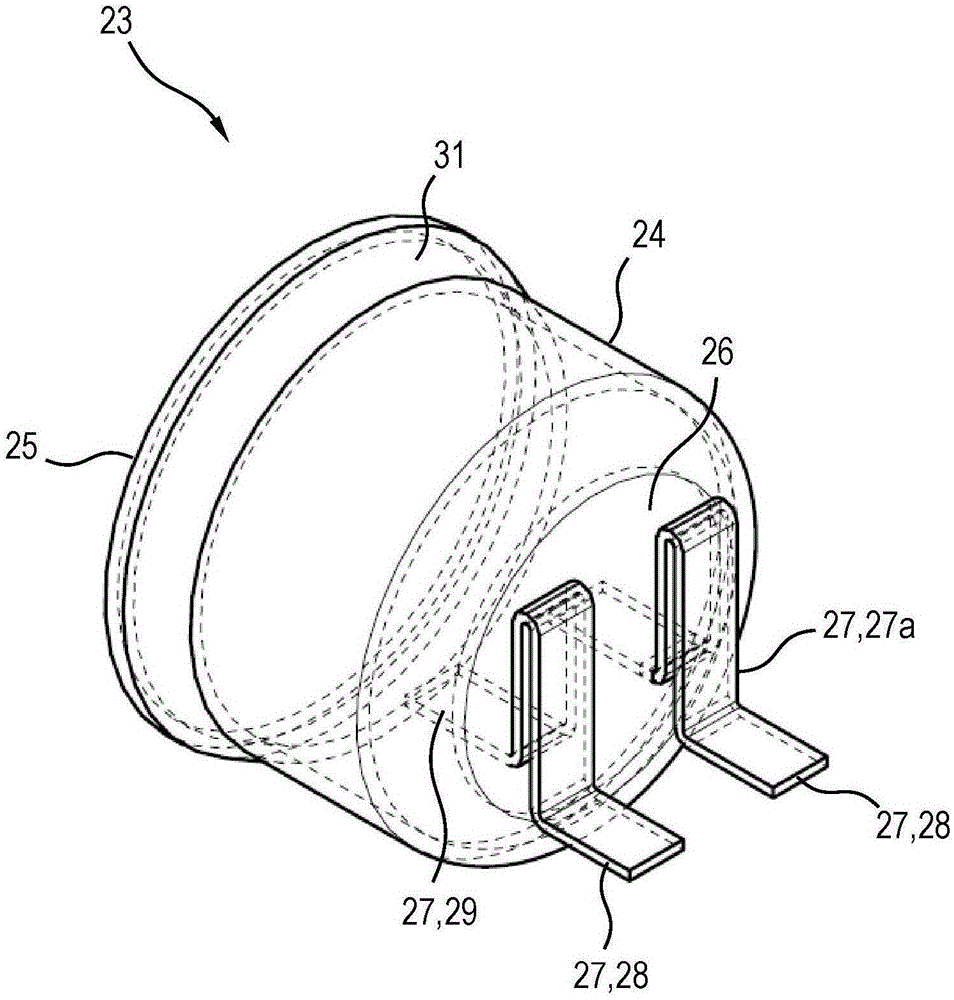

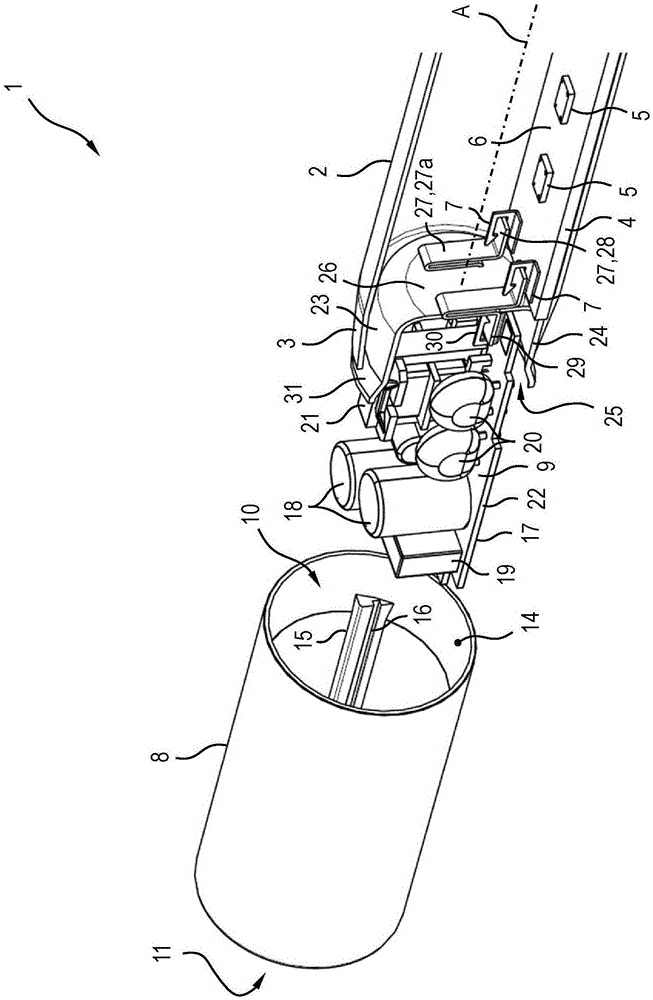

[0040] figure 1 A section through the not yet assembled end-side parts of a semiconductor lighting device, which is designed in the form of an LED retrofit lamp 1 for replacing, for example, a T5 or T8, is shown in a partial sectional view at an oblique angle of view. A type of conventional fluorescent lamp collaborator that replaces linear lamps.

[0041] The LED retrofit lamp 1 has a tubular bulb 2 shown in cutaway with the basic shape of a hollow cylinder, which is made of a light-transmissive (for example transparent or translucent or opaque) material such as glass or synthetic material . The bulb 2 has a constricted end region 3 . This region has an inclination angle relative to the longitudinal axis A of between 5° and 7° in the longitudinal section along the longitudinal axis A of the bulb 2 and thus of the LED retrofit lamp 1 .

[0042] A light source substrate in the form of a strip-shaped printed circuit board 4 , which is equipped with semiconductor light sources...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com