Air Conditioning System

An air-conditioning system and interface technology, applied in the direction of compressors with reversible cycles, lighting and heating equipment, fluid circulation arrangements, etc., can solve problems such as reducing the performance of air conditioners, compressor damage, etc. The effect of increasing the amount of refrigerant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

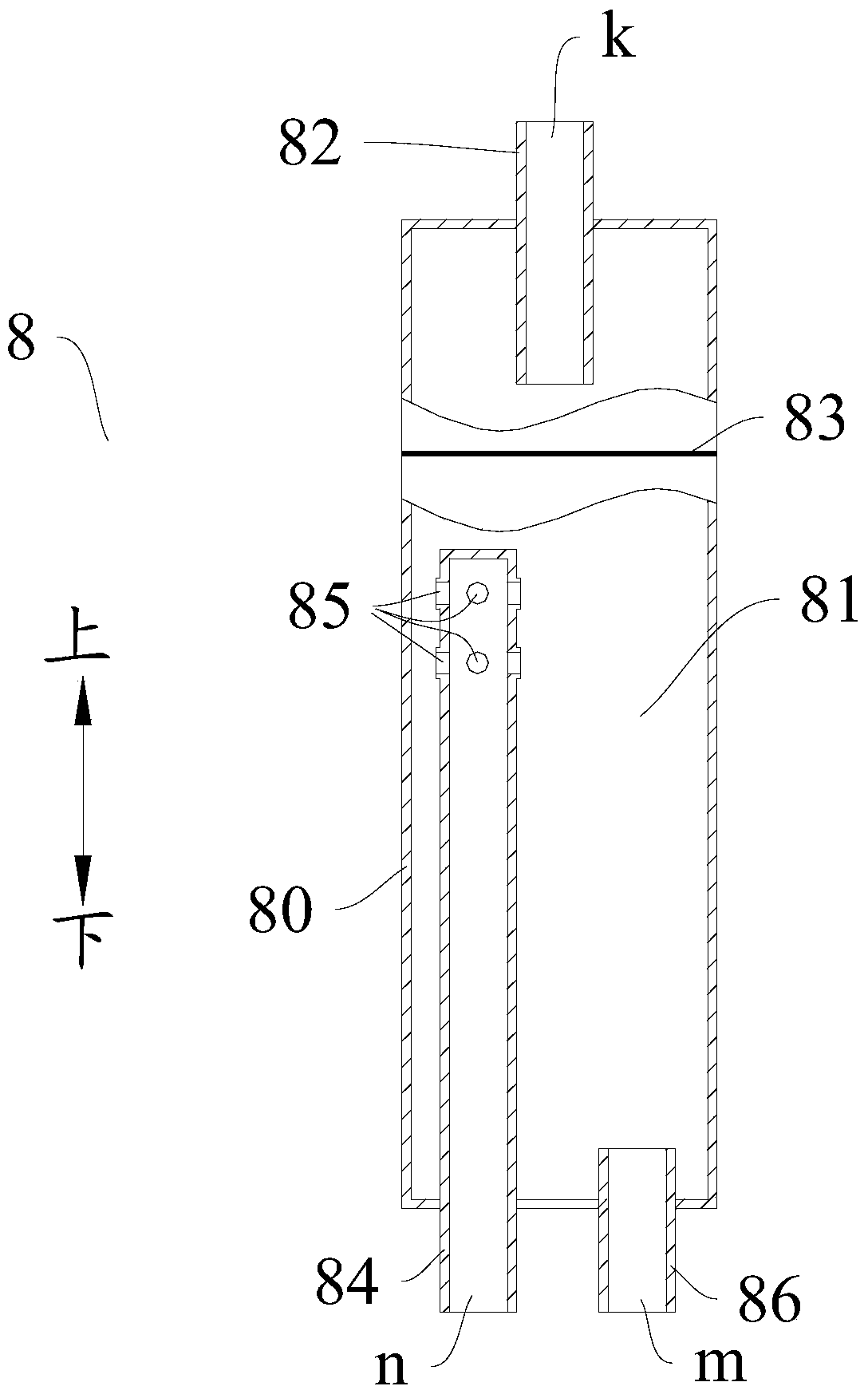

[0048] Such as figure 2 As shown, in this embodiment, the gas-liquid separator 8 includes: a housing 80 , an input pipe 82 , a filter 83 , an air outlet pipe 84 and a liquid outlet pipe 86 , wherein a separation space 81 is defined inside the housing 80 . The input pipe 82 protrudes from the top of the casing 80 into the separation space 81 , and the port of the input pipe 82 outside the casing 80 defines an input port k. The filter screen 83 is arranged in the separation space 81 and below the input pipe 82 to separate gas and liquid and filter impurities. The gas outlet pipe 84 extends from the bottom wall of the casing 80 into the separation space 81 , and the port of the gas outlet pipe 84 outside the casing 80 defines a gas output port n. The liquid outlet pipe 86 extends from the bottom wall of the housing 80 into the separation space 81 , and the port of the liquid outlet pipe 86 outside the housing 80 defines a liquid outlet m.

[0049] The port of the air outlet pi...

Embodiment 2

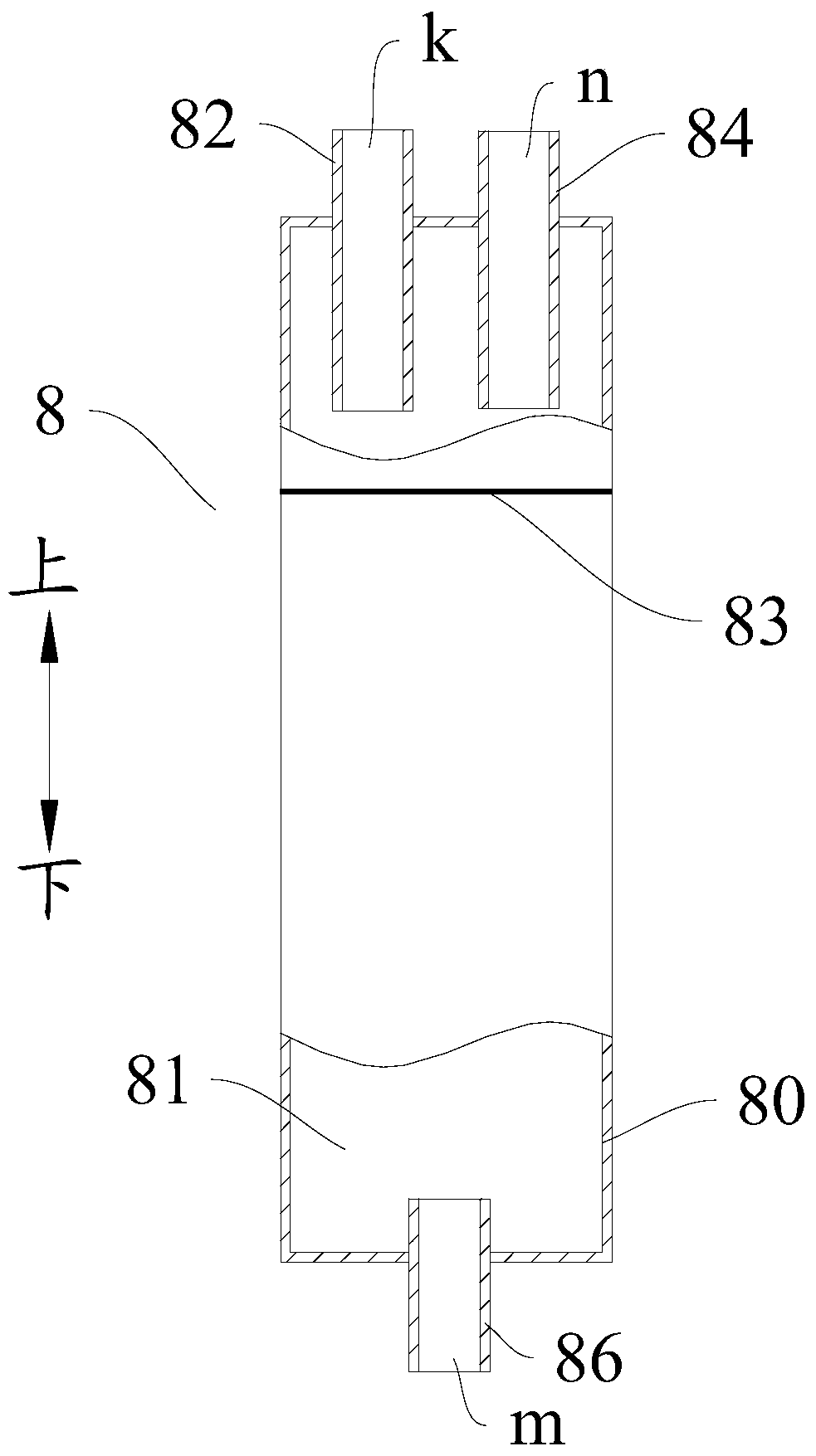

[0054] Such as image 3 As shown, in this embodiment, different from Embodiment 1, the air outlet pipe 84 protrudes from the top wall of the housing 80 into the separation space 81 and the lower end of the air outlet pipe 84 is located above the filter screen 83 .

[0055] In this embodiment, the gas-liquid mixed refrigerant that enters the separation space 81 from the input pipe 82 is separated from the gas and liquid under the double action of gravity and the filter screen 83, and the separated gas refrigerant enters from the lower end of the outlet pipe 84 into the The gas outlet pipe 84 enters the air outlet c from the gas outlet n, and the separated liquid refrigerant enters the liquid outlet pipe 86 from the upper end of the liquid outlet pipe 86 and is discharged from the liquid outlet m.

[0056] It should be noted that in this embodiment, other structures of the gas-liquid separator 8, such as the structure of the housing 80, the installation position of the input pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com