Adjustable Boiler Water Cooling Sampling Gun Device and Sampling Method

A sampling gun and water-cooling technology, which is applied in the direction of sampling device, test sample preparation, etc., can solve the problem that the sampling gun is difficult to withstand the high temperature of the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

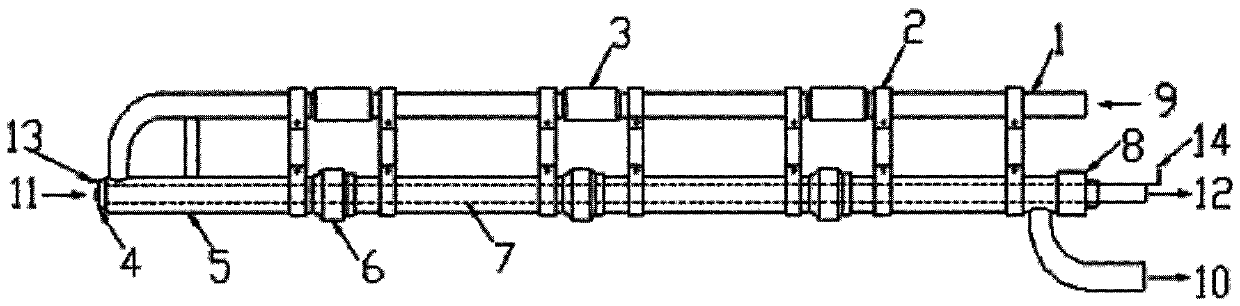

[0008] The invention is a detachable multi-stage water-cooling gun that can operate safely in a high temperature environment. A circulating water cooling pipeline is installed on the sampling gun. The cooling water inlet pipeline and the cooling water outlet pipeline are connected to each other through a high temperature-resistant metal bracket, and the sample sampling tube is sleeved inside the water outlet pipeline. Multi-section stainless steel water-cooling components are assembled through threaded connections to form a water-cooling gun, and the sealing between the water-cooling components is achieved by red copper gaskets. Considering the test chamber, field installation and shipping conditions, the length of the sampling gun can be composed of different lengths of water-cooled components.

[0009] The following description will be given in conjunction with the accompanying drawings.

[0010] The water-cooled sampling gun mainly includes a sampling pipe and a circulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com