Capillary bundle flow measurement device and measurement method for nanoemulsion

A technology of capillary bundles and nanoemulsions, applied in the direction of direct current flow characteristics measurement, etc., can solve problems such as difficult to reproduce, long time, non-reproducibility, etc., to improve the accuracy of measurement, reduce operating errors, and solve the effect of preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

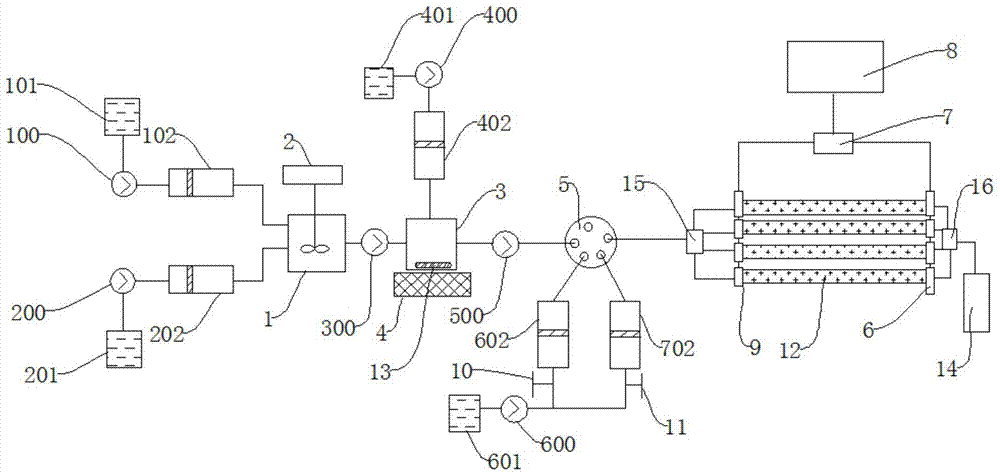

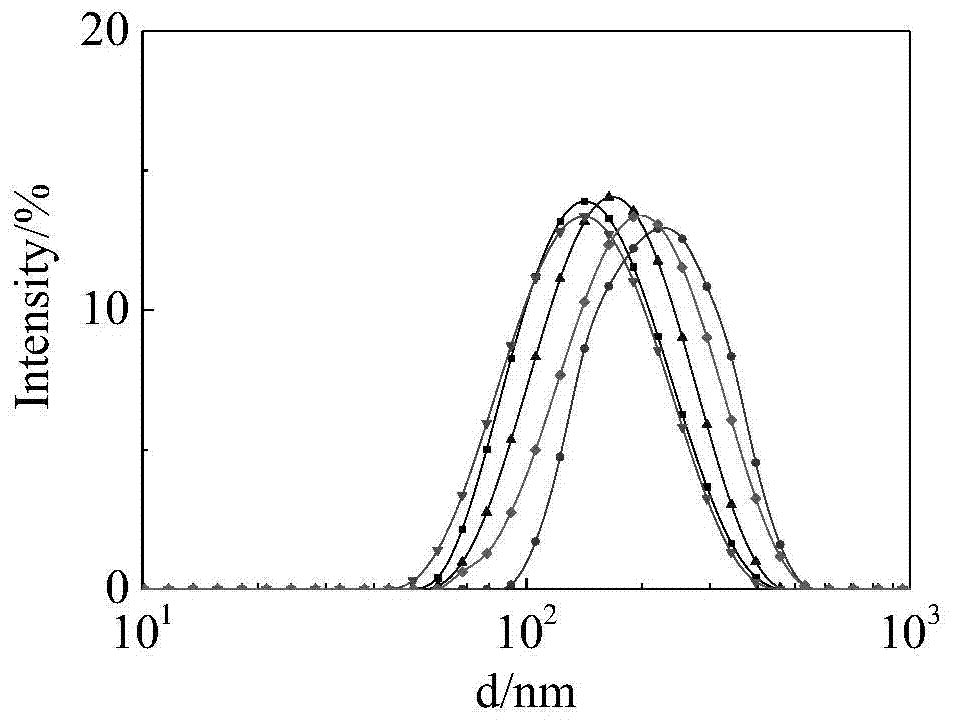

[0051] Based on 100 parts by weight, the nanoemulsion includes the following components: liquid paraffin 20 parts, non-ionic surfactant Span 20 accounts for 4.88 parts, Tween 20 accounts for 5.12 parts, and the balance is deionized water. The mechanical stirring rate is 750 revolutions per minute, the electromagnetic stirring rate is 100 revolutions per minute, the temperature is 25°C, the rate of the first injection pump is 0.5 mL / min, and the rate of the fourth injection pump is 9.99 mL / min. The length of the capillary is 1m, the inner diameter is 0.2mm, and the number is 10. The data acquisition system collects pressure changes and obtains the flow of nanoemulsion in the capillary bundle. The particle size of the nanoemulsion under different conditions is measured and characterized by a nano laser particle size analyzer.

Embodiment 2

[0053] The nanoemulsion is based on 100 parts by weight and includes the following components: liquid paraffin accounts for 20 parts, non-ionic surfactant Span 20 accounts for 4.88 parts, Tween 20 accounts for 5.12 parts, and the balance is deionized water. The mechanical stirring rate is 750 revolutions per minute, the electromagnetic stirring rate is 1000 revolutions per minute, the temperature is 25°C, the rate of the first injection pump is 0.5 mL / min, and the rate of the fourth injection pump is 9.99 mL / min. The length of the capillary is 1m, the inner diameter is 0.2mm, and the number is 10. The data acquisition system collects pressure changes and obtains the flow of nanoemulsion in the capillary bundle.

Embodiment 3

[0055] The nanoemulsion is based on 100 parts by weight and includes the following components: liquid paraffin accounts for 20 parts, non-ionic surfactant Span 20 accounts for 4.88 parts, Tween 20 accounts for 5.12 parts, and the balance is deionized water. The mechanical stirring rate is 750 revolutions per minute, the electromagnetic stirring rate is 100 revolutions per minute, the temperature is 25°C, the rate of the first injection pump is 0.5 mL / min, and the rate of the fourth injection pump is 9.99 mL / min. The length of the capillary is 0.5m, the inner diameter is 0.2mm, and the number is 10. The data acquisition system collects pressure changes and obtains the flow of nanoemulsion in the capillary bundle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com