Measurement device and measurement method for measuring flow of capillary tube bundle for nano-emulsion

A capillary bundle and nanoemulsion technology, which is used in the measurement of DC flow characteristics, can solve the problems of difficulty in reproducibility, long time and irreproducibility, and achieve the effect of improving the accuracy of measurement, reducing operating errors and solving the preparation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

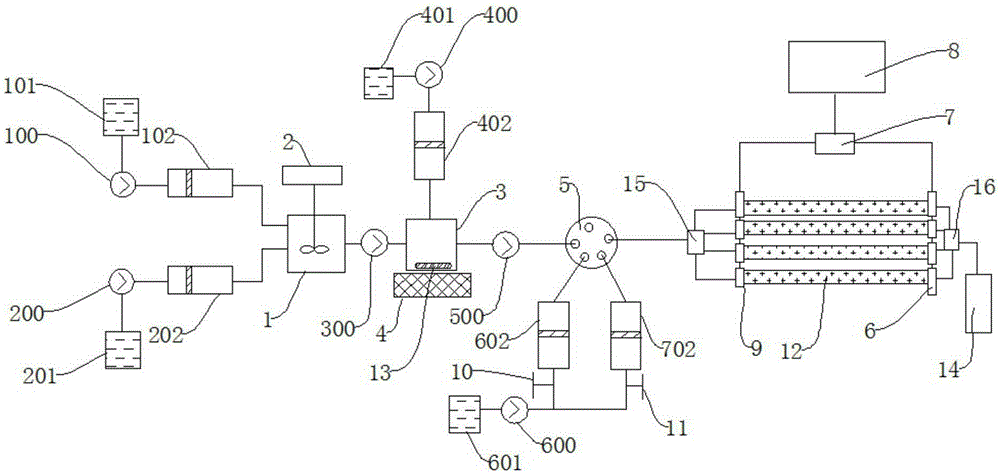

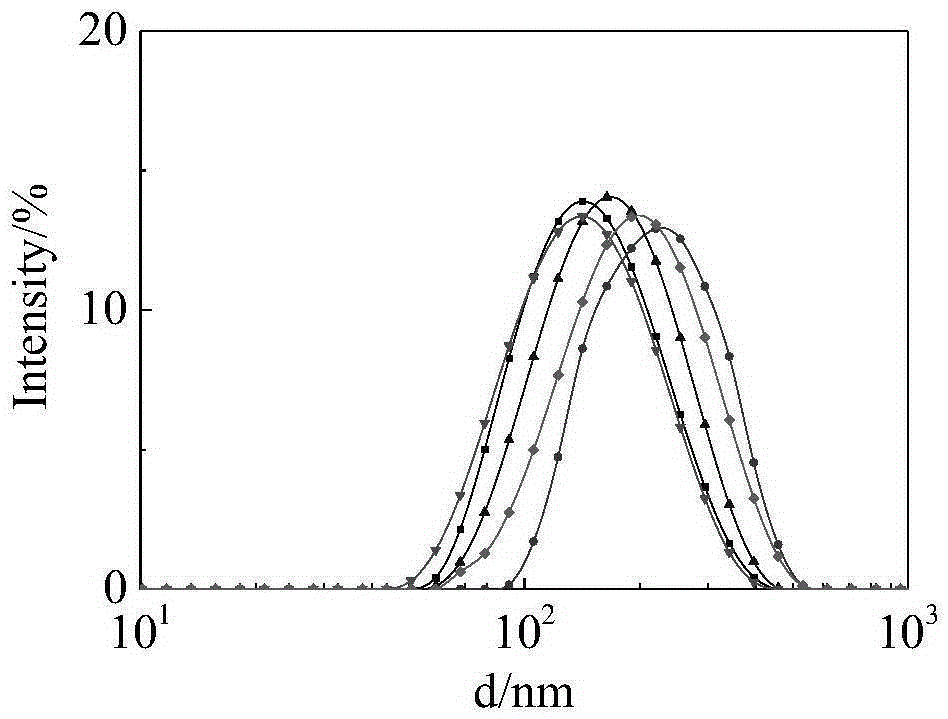

[0051] The nanoemulsion comprises the following components based on 100 parts by weight: liquid paraffin accounts for 20 parts, nonionic surfactant Span 20 accounts for 4.88 parts, Tween 20 accounts for 5.12 parts, and the balance is deionized water. The mechanical stirring rate is 750 rpm, the electromagnetic stirring rate is 100 rpm, the temperature is 25°C, the rate of the first injection pump is 0.5mL / min, and the rate of the fourth injection pump is 9.99mL / min. The length of the capillary is 1m, the inner diameter is 0.2mm, and the number is 10. The change of the pressure is collected by the data acquisition system to obtain the flow of the nanoemulsion in the capillary bundle. The particle size of the nanoemulsion under different conditions was measured and characterized by a nanometer laser particle size analyzer.

Embodiment 2

[0053] The nanoemulsion comprises the following components based on 100 parts by weight: liquid paraffin accounts for 20 parts, nonionic surfactant Span 20 accounts for 4.88 parts, Tween 20 accounts for 5.12 parts, and the balance is deionized water. The mechanical stirring rate is 750 rpm, the electromagnetic stirring rate is 1000 rpm, the temperature is 25°C, the rate of the first injection pump is 0.5mL / min, and the rate of the fourth injection pump is 9.99mL / min. The length of the capillary is 1m, the inner diameter is 0.2mm, and the number is 10. The change of the pressure is collected by the data acquisition system to obtain the flow of the nanoemulsion in the capillary bundle.

Embodiment 3

[0055] The nanoemulsion comprises the following components based on 100 parts by weight: liquid paraffin accounts for 20 parts, nonionic surfactant Span 20 accounts for 4.88 parts, Tween 20 accounts for 5.12 parts, and the balance is deionized water. The mechanical stirring rate is 750 rpm, the electromagnetic stirring rate is 100 rpm, the temperature is 25°C, the rate of the first injection pump is 0.5mL / min, and the rate of the fourth injection pump is 9.99mL / min. The length of the capillary is 0.5m, the inner diameter is 0.2mm, and the number is 10. The change of the pressure is collected by the data acquisition system to obtain the flow of the nanoemulsion in the capillary bundle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com