Large light-transmitting space enclosing structure heat transfer coefficient detection equipment and method

A technology of heat transfer coefficient and envelope structure, which is applied in the field of equipment for large-scale light-transmitting envelope structure heat transfer coefficient, can solve problems affecting indoor thermal comfort, increase air-conditioning energy consumption, and poor indoor thermal environment, etc., and achieve high detection The effect of improving precision and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

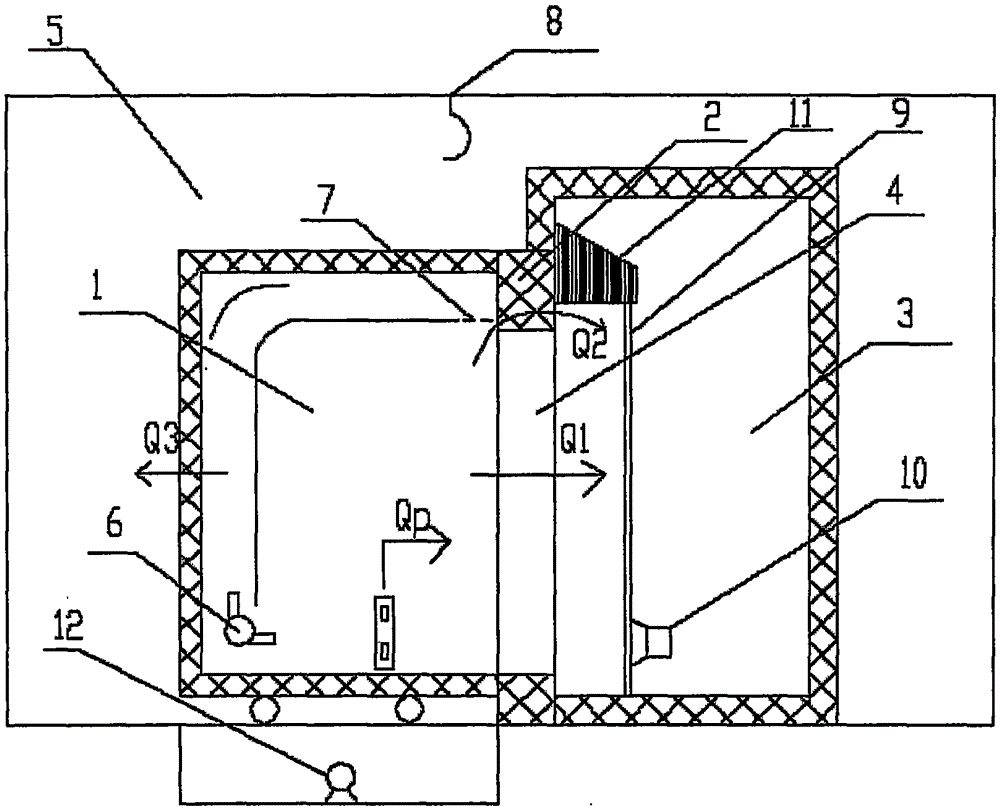

[0011] Such as figure 1 As shown, the hardware of the large-scale light-transmitting enclosure structure heat transfer coefficient detection equipment is mainly composed of an environmental chamber 5, a hot box 1, a specimen frame 2, a cold box 3, and a hoisting device 8, wherein the hot box 1 is also called "heat metering box", because all the temperature measuring points and power measuring points are placed on the side of the hot box 1. Compared with the cold box 3, in addition to the function of forming a specific temperature field and velocity field, the hot box 1 also needs to complete the entire The measurement function of the test process; in addition, in terms of software, the testing equipment also has an automatic control program and a data acquisition program. figure 1 middle, Q 1 is the heat transfer through the test pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal resistance | aaaaa | aaaaa |

| Thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com