Sequential control operation order automatic anti-error check method based on simulation IED device

An operation ticket and error prevention technology, which is applied in program control, general control system, electrical testing/monitoring, etc., can solve the problems that the sequence control function cannot be put into actual operation, time-consuming and laborious, and lack of item-by-item verification, so as to improve the usability, The effect of ensuring safety and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

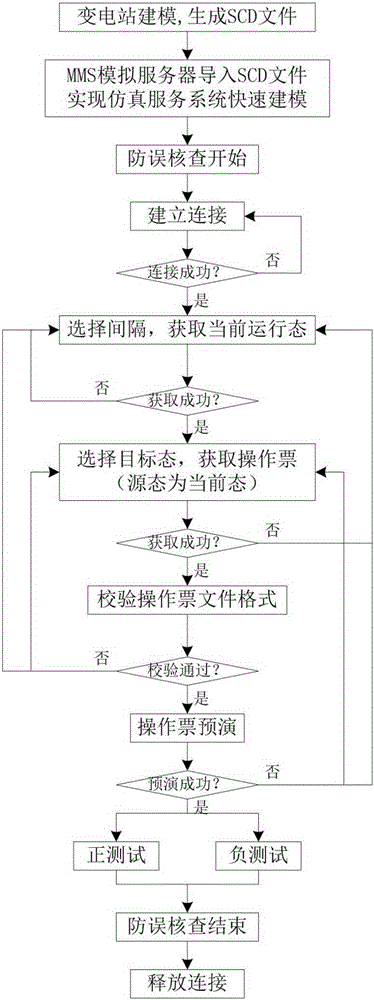

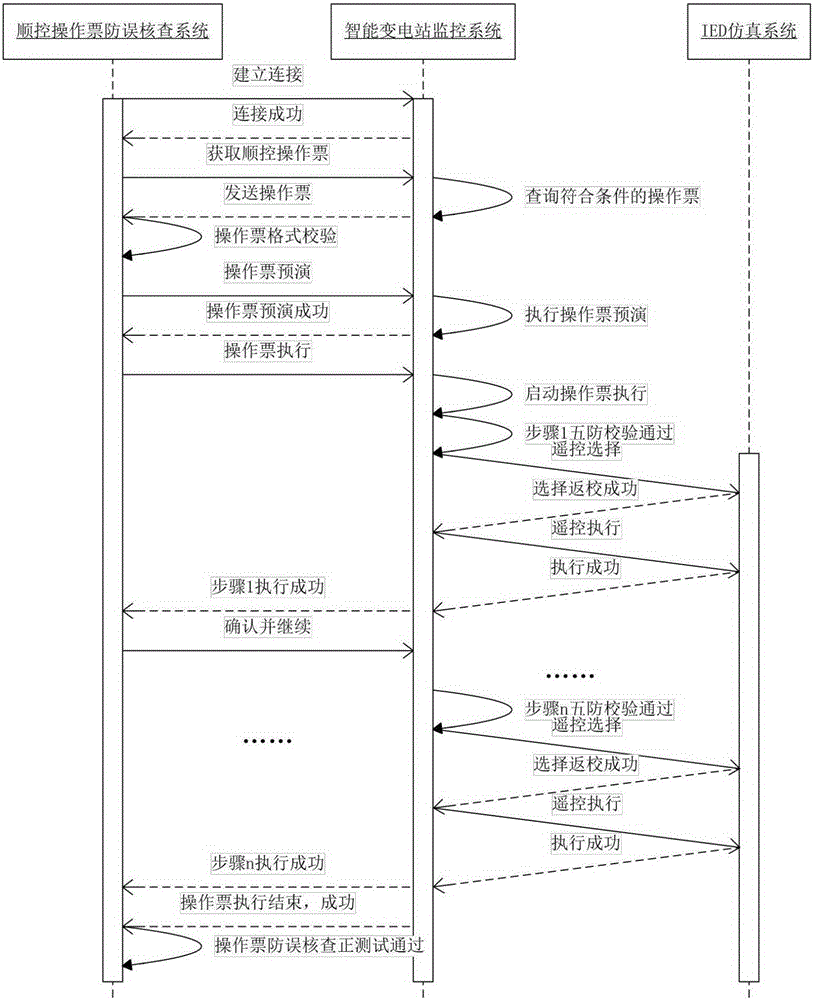

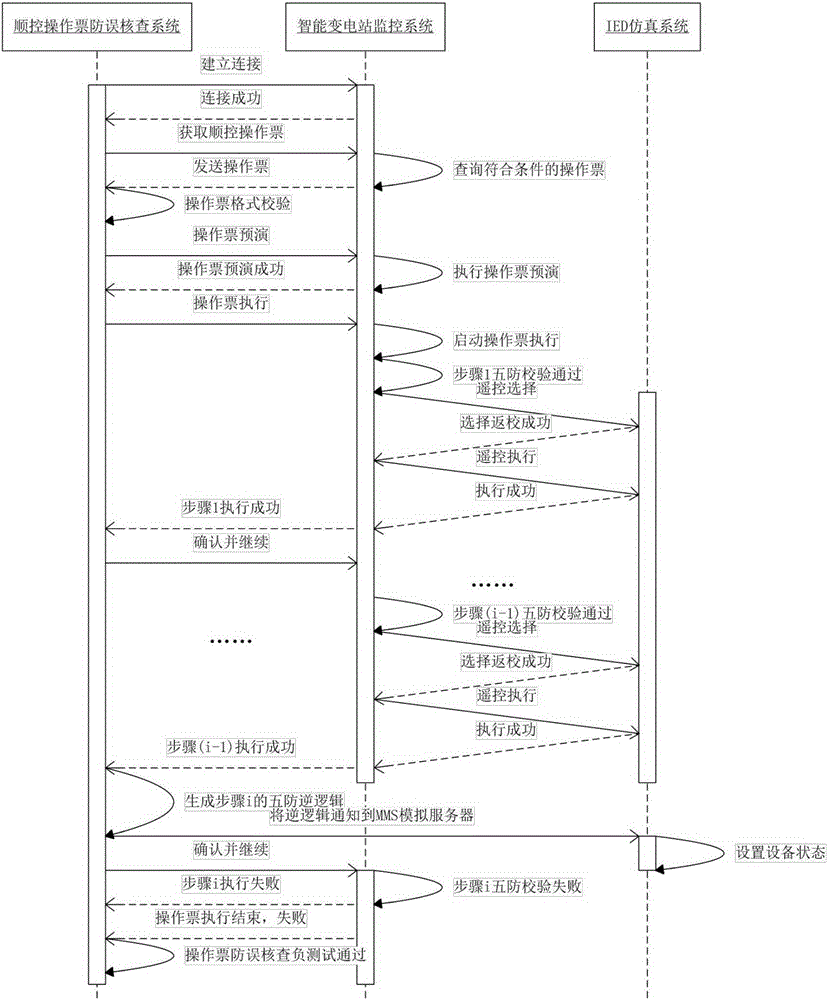

[0044] The automatic error prevention verification method for sequential control operation tickets based on the simulated IED device comprises the following steps:

[0045] Step 1. Use the system configuration tool of the smart substation to configure and generate the SCD model file of the smart substation;

[0046] Step 2. Simulate the IED model of the intelligent substation

[0047] Import the SCD model file of the smart substation into the IEC61850MMS simulation service system to build the protection, measurement and control secondary equipment model of the whole station;

[0048] Step 3, the operation ticket error prevention verification system obtains the sequential control operation ticket from the intelligent substation monitoring system;

[0049] (1) Establish a connection between the operation ticket error prevention verification system and the intelligent substation monitoring system. The operation ticket error prevention verification system obtains the current oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com