Metal layer-insulator layer-metal layer capacitor and manufacturing method thereof

A manufacturing method and metal layer technology, applied in the direction of electrical solid-state devices, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as the inability to meet the needs of large-capacity integrated circuits, achieve large capacitance values, and increase capacitance density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

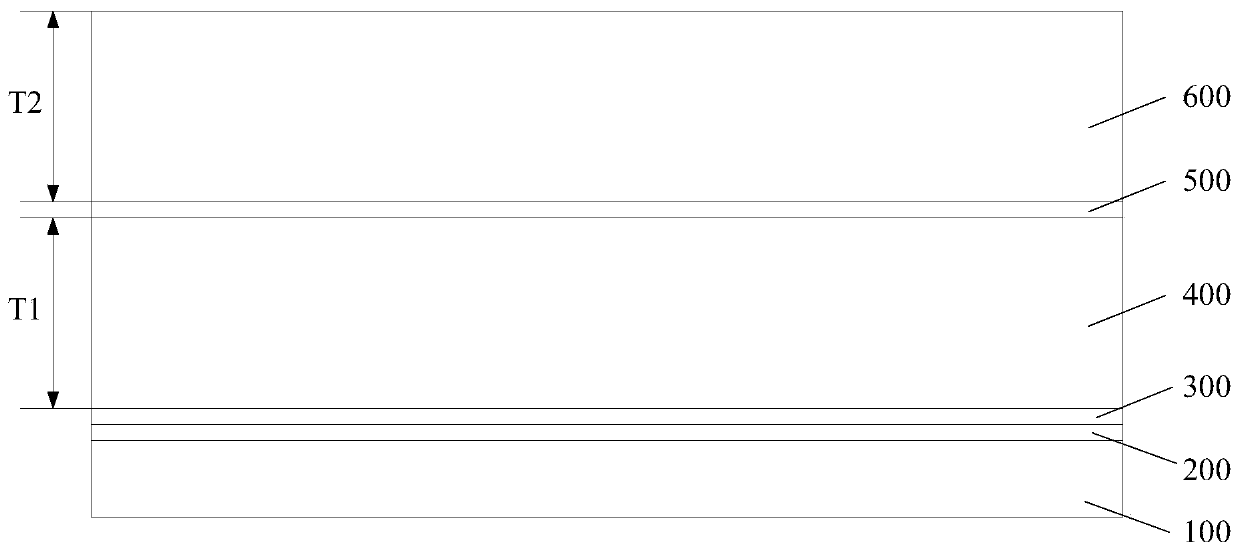

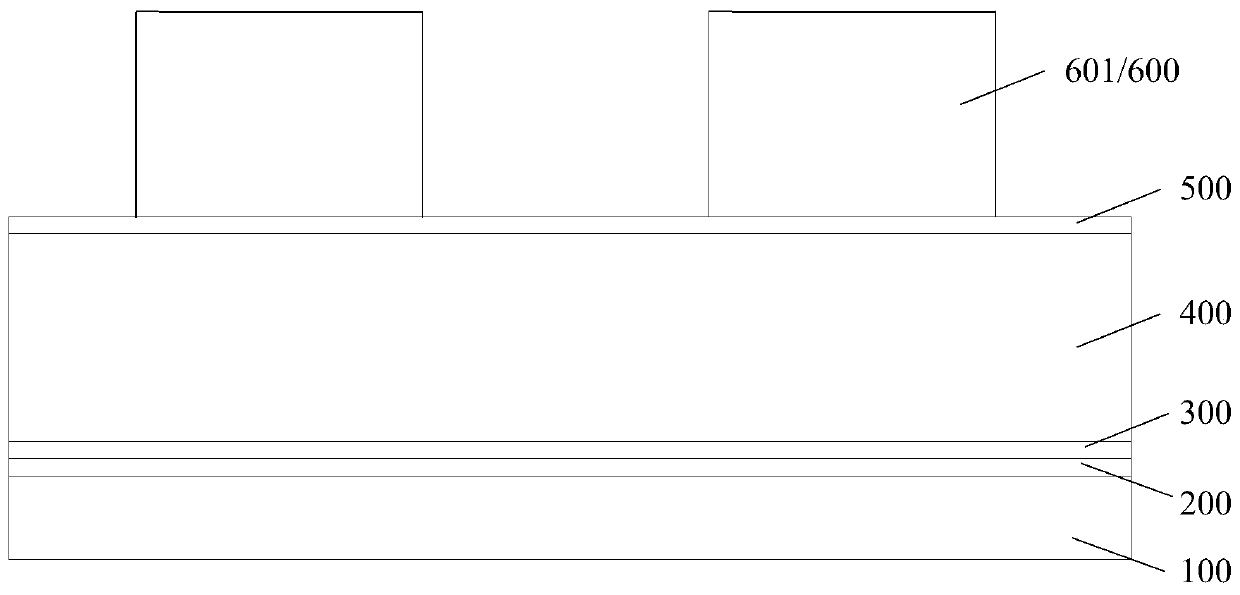

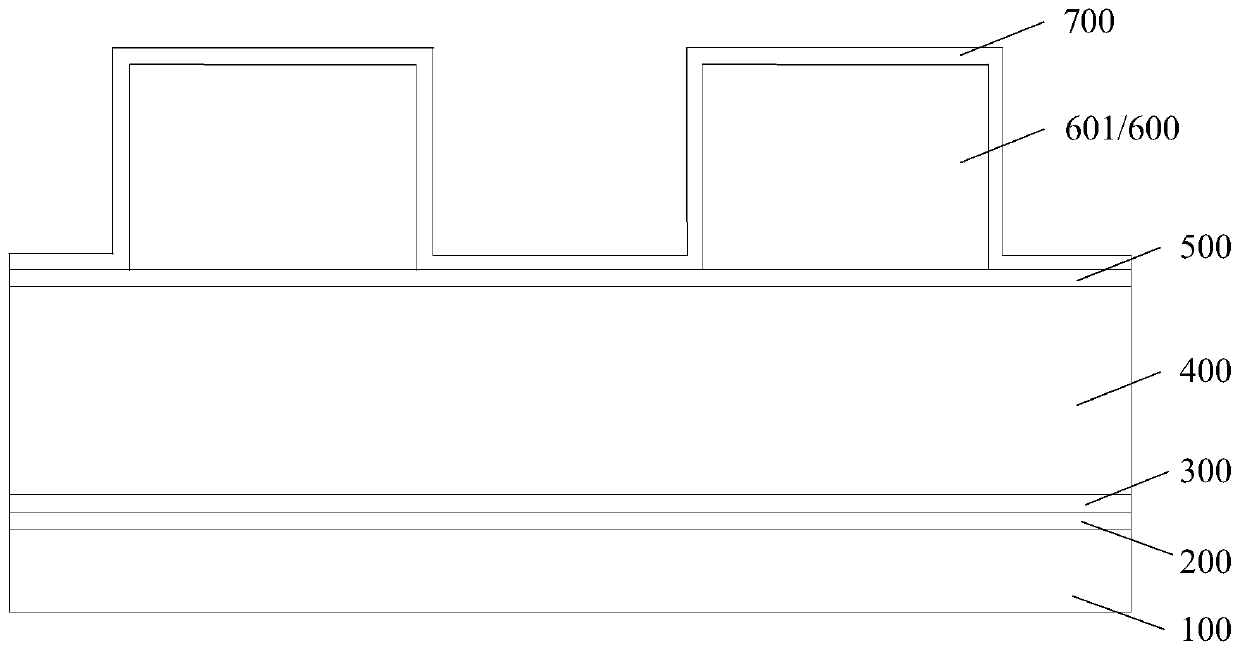

[0039] Figure 1-Figure 10 It is a process schematic diagram of the manufacturing method of the metal layer-insulation layer-metal layer capacitor according to Embodiment 1 of the present invention.

[0040] see figure 1 , providing a first metal layer 100, defining a non-capacitive area and a capacitive area on the first metal layer 100, figure 1 Only the structure of the capacitive region is shown here, and the structure of the non-capacitive region is not shown.

[0041] In the capacitor area, the first dielectric layer 400 , the third barrier layer 500 , and the second dielectric layer 600 are sequentially formed on the surface of the first metal layer 100 . Wherein, the thickness T1T1 of the first dielectric layer 400 is 50 nm-5 μm, and the thickness T2 of the second dielectric layer 600 is 50 nm-5 μm.

[0042] In addition, the adhesion layer 200 and the second barrier layer 300 are preferably sequentially formed on the first metal layer 100 before the step of formin...

Embodiment 2

[0069] Figure 11-Figure 20 It is a process schematic diagram of the manufacturing method of the metal layer-insulation layer-metal layer capacitor according to Embodiment 2 of the present invention.

[0070] see Figure 11 , providing a first metal layer 2100, defining a non-capacitive area and a capacitive area on the first metal layer 2100, Figure 11 Only the structure of the capacitive region is shown here, and the structure of the non-capacitive region is not shown.

[0071] In the capacitor area, a first dielectric layer 2400 is formed on the surface of the first metal layer 2100 . Wherein, the total thickness of the first dielectric layer 2400 is T0. In addition, preferably before the step of forming the first dielectric layer 2400 , the adhesion layer 2200 and the second barrier layer 2300 are sequentially formed on the first metal layer 2100 . Wherein, the adhesion layer 2200 is usually a TiN layer, and the second barrier layer 2300 can be any one or a combinatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com