Manufacturing method of capacitor

A manufacturing method and technology of capacitors, which can be used in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., and can solve problems such as large leakage current and reduced linearity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

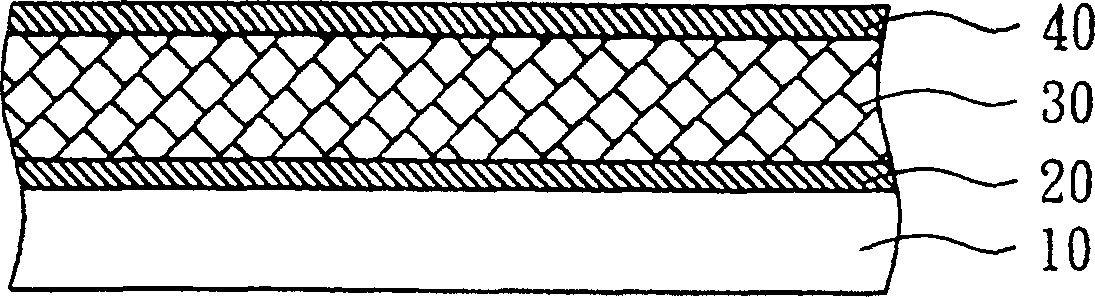

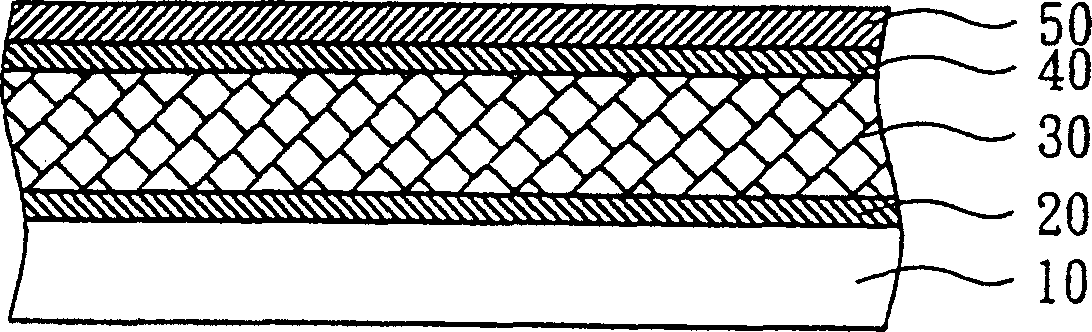

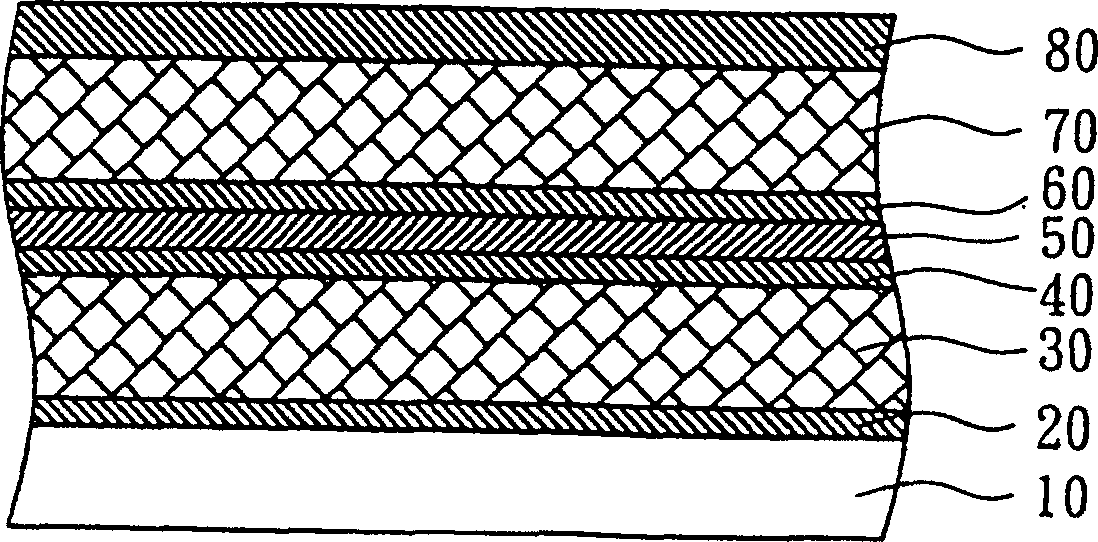

[0058] The invention relates to a manufacturing method of a three-dimensional MIM capacitor. Figure 2A to Figure 2N It is a cross-sectional view of the structure of the manufacturing method of the three-dimensional MIM capacitor according to the first preferred embodiment of the present invention. Such as Figure 2A Firstly, a substrate 210 is provided, wherein some CMOS devices (not shown) have been pre-formed on the substrate 210 . Next, an adhesive layer 220 is formed on the base material 210, wherein the material of the adhesive layer 220 can be titanium nitride, and the thickness of the adhesive layer 220 can be about 250 Å, for example. The purpose of this adhesive layer 220 is to strengthen the adhesion between the metal layer and the substrate 210 in the subsequent process and as a barrier layer, and the purpose of other adhesive layers in this specification is to strengthen the metal layer and other layers. Adhesion as well as acting as a barrier layer. Next, a me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com