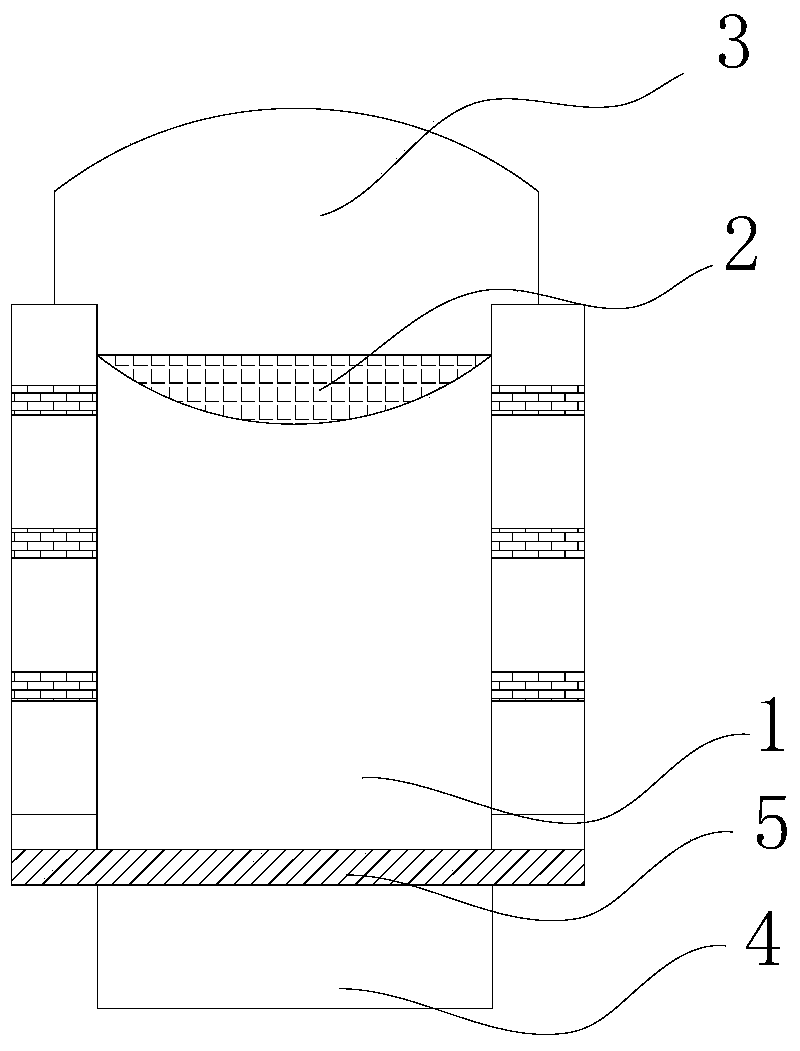

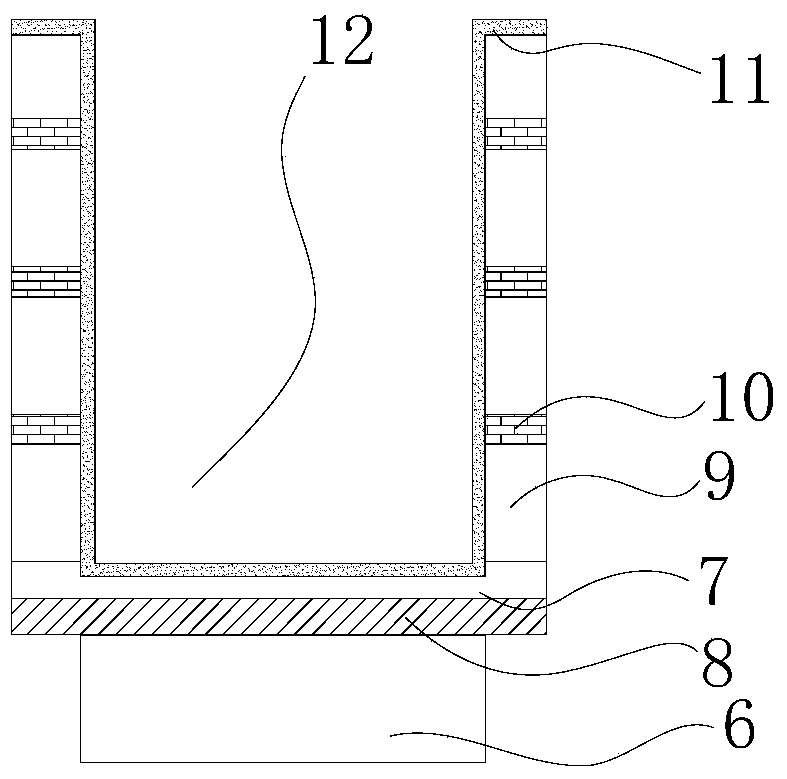

Structure of a CMOS image sensor and preparation method thereof

An image sensor and silicide technology, applied in radiation control devices and other directions, can solve problems such as light source loss, reduce the loss of reflected light, improve product yield, and increase intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A method for preparing a CMOS image sensor, characterized in that the method includes providing the photodiode region, and disposing the contact etching barrier layer on the photodiode region;

[0038] Depositing a silicide mask layer on the upper end of the contact etching barrier layer, wherein the total thickness of the silicide mask and the contact etching barrier layer is controlled to be greater than 1 / 4 of the wavelength of the incident light source;

[0039] Etching part of the silicide mask layer, wherein the total thickness of the etched silicide mask and the contact etching barrier layer is less than 1 / 4 of the wavelength of the incident light source;

[0040] depositing the dielectric layer on the surface of the etched silicide mask layer, and using the silicide mask as a stop layer to etch the dielectric layer to form the optical channel deep groove;

[0041] Deposit and form the protective layer film on the entire product surface after etching, wherein the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com