A steel ladle positioning sensor bracket and the steel ladle can be positioned

A technology of positioning sensor and radio frequency sensor, which is used in casting melt containers, metal processing equipment, casting equipment, etc., can solve the problem of high temperature, achieve the effect of simple structure, safe and reliable long-term operation, and solve the problems of heat insulation and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

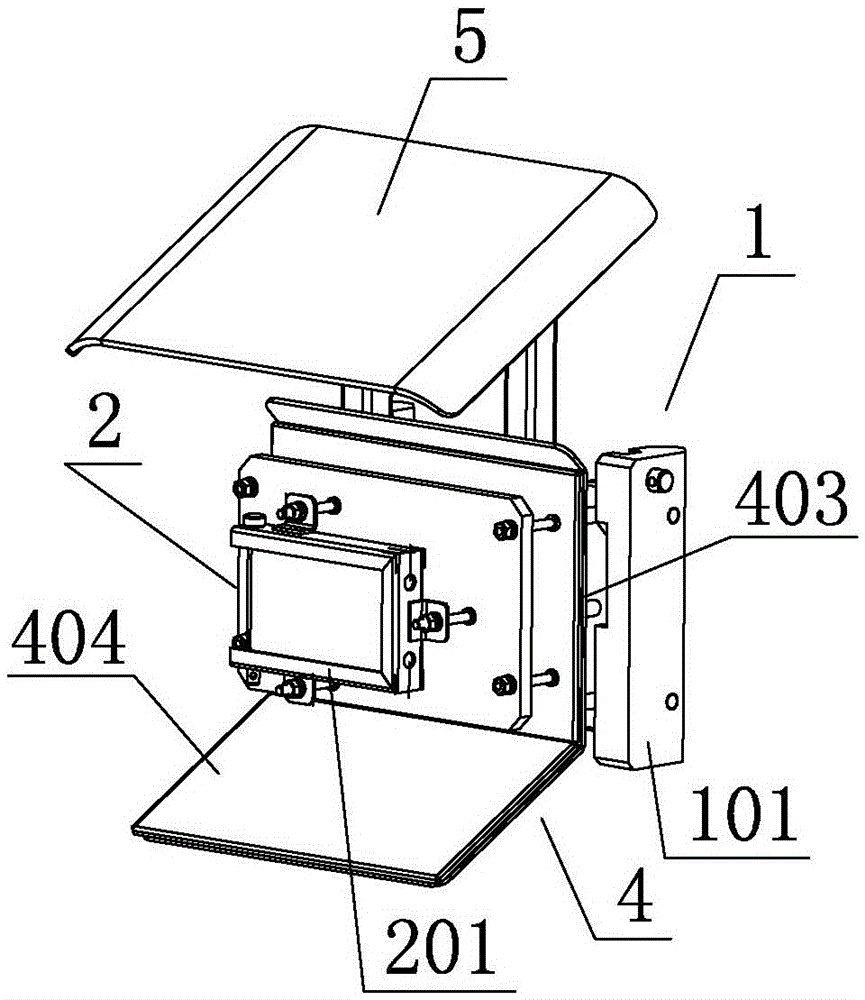

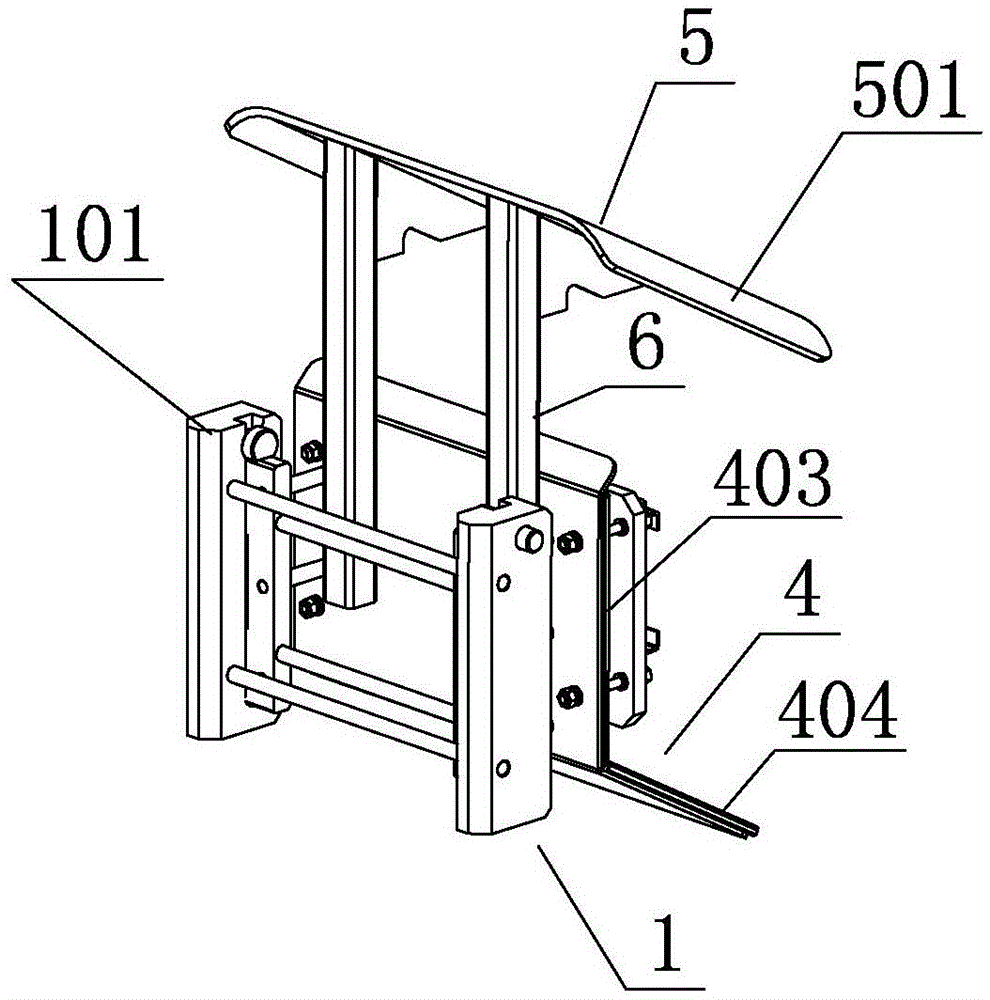

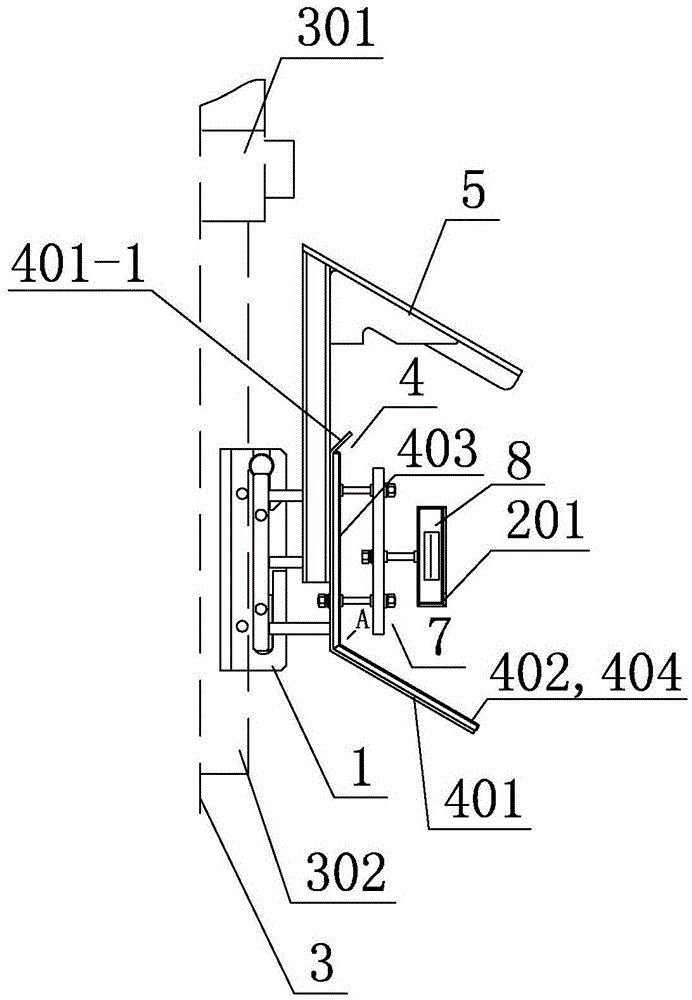

[0021] A ladle positioning sensor bracket, such as figure 1 , 2 , 3, including a steel mounting frame 1 fixed to the ladle side wall and a radio frequency sensor box mounting seat 2, the mounting frame 1 has two fixed plates 302 connected and fixed with the steel ladle 3 hook 301 lower side wall Elongated connection block 101; a thermal insulation plate 4 is provided between the mounting frame and the mounting seat, and a downwardly inclined protective cover 5 is provided above the thermal isolation plate and the mounting seat, and the left and right sides of the protective cover are bent inward 501, the protective cover is fixed on the connection block 101 through the support frame 6, and the protective cover is used to prevent molten steel slag from flying out of the ladle and falling on the wireless signal sensor box, so as to prevent dust; wherein, for heat insulation, the The heat insulation board has at least two layers, wherein, one layer on the side of the installatio...

Embodiment 2

[0027] A positionable ladle such as image 3 As shown, it includes a ladle 3 and a radio frequency sensor for transporting molten steel. The radio frequency sensor is packaged in a sealed box 8. The sealed box is a sealed box in which the radio frequency sensor is encapsulated by epoxy resin. The sealed box is set on the steel ladle 3 through a bracket. On the side wall under the position of the hook 301, the radio frequency sensor establishes contact with the radio frequency generator by reflecting the received radio frequency signal to locate the ladle, wherein the support includes a steel mounting frame fixed to the side wall of the ladle and a sealed radio frequency sensor Box mounting seat 2, mounting frame 1 has two elongated connection blocks 101 connected and fixed with fixed plate 302 that steel ladle 3 suspension hook 301 lower side wall is provided with; Same as embodiment 1: therefore snap into figure 1 , 2 , 3, a thermal isolation plate 4 is provided between the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com