Method for proportioning pump constant power control for bedding-in hydraulic machine

A constant power control and proportional pump technology, applied in the field of compressors, can solve the problems of reducing design and production costs, constant limited use efficiency, and failure to take advantage of proportional pumps, so as to prevent overcurrent and reduce design and production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

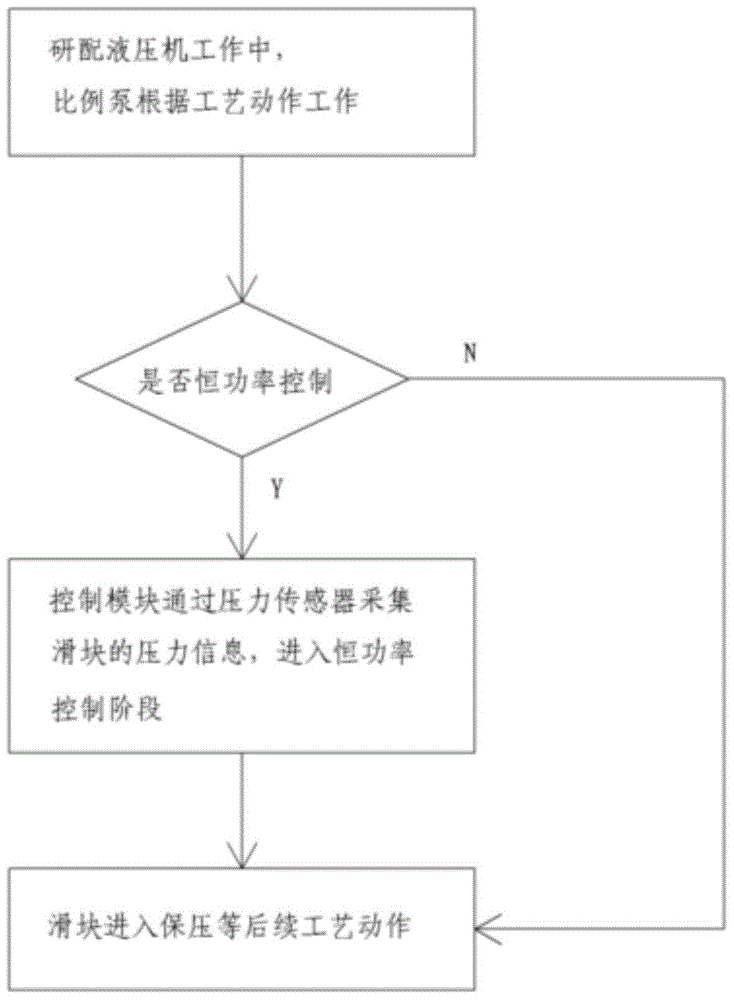

[0016] see figure 1 , a proportional pump constant power control method for researching and distributing hydraulic presses, comprising the following steps:

[0017] Step 1. During the working process of the research and distribution hydraulic machine, the proportional pump changes the opening of the spool through the amplifying plate according to the process action to output different flow rates, thereby ensuring the downward running speed and beat of the slider. The control module judges whether the motor should enter constant power control;

[0018] Step 2. The control module reads the power signal of the instrument. If the actual power P of the motor is equal to or exceeds the rated power P0 for more than 0.3s, then perform step 3. If the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com