Automatic tube feeding and discharging device for light bar pasting process of T8LED lamp tube full-automatic production line

An automatic device, fully automatic technology, applied in packaging, labeling machine, transportation and packaging, etc., can solve the problems of low production efficiency, large loss, increase production cost, etc., and achieve the effect of improving efficiency and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

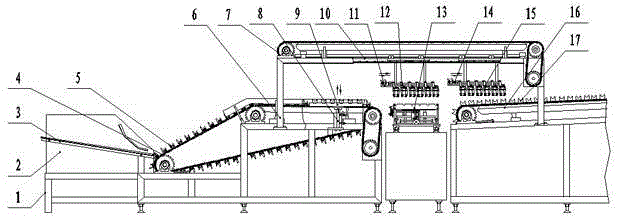

[0015] The present invention includes a frame 1 and an automatic tube loading transmission device 4 arranged on the frame 1, and a glue machine 13 is arranged behind the automatic tube loading transmission device 4;

[0016] Described automatic upper tube transfer device 4 is provided with a lamp tube holder 5 for clamping the lamp tube, and the rear end of the automatic upper tube transfer device 4 is provided with a custodial seat 9 that can be lifted up and down. There is a lamp tube clamping seat 5 for clamping the lamp tube, and the stinger seat 9 and the automatic tube loading transfer device 4 are laterally staggered so that the stinger seat 9 can protrude from the automatic tube loading transfer device 4;

[0017] The upper part of the automatic upper and lower pipe transfer device 4 is provided with an automatic upper and lower pipe moving device 7, and the automatic upper and lower pipe moving track 10 is provided on the automatic upper and lower pipe moving device 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com