Hollow door

A hollow, panel technology, applied in door leaves, electrical components, semiconductor/solid device manufacturing, etc., can solve problems such as temperature loss, low temperature, and difficult maintenance of internal temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

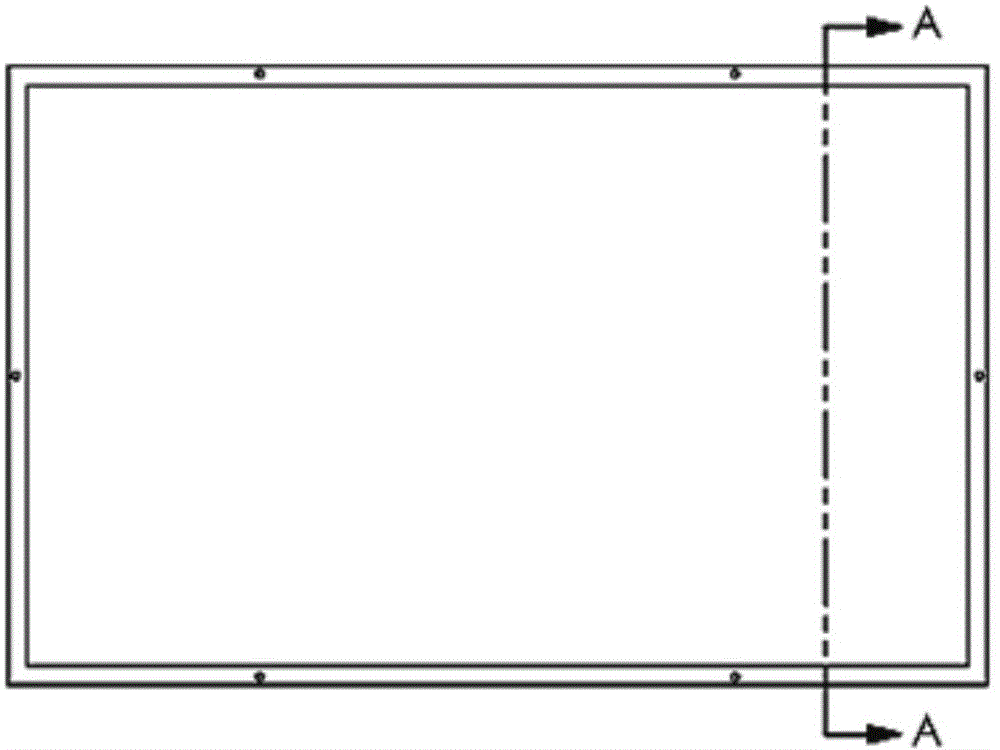

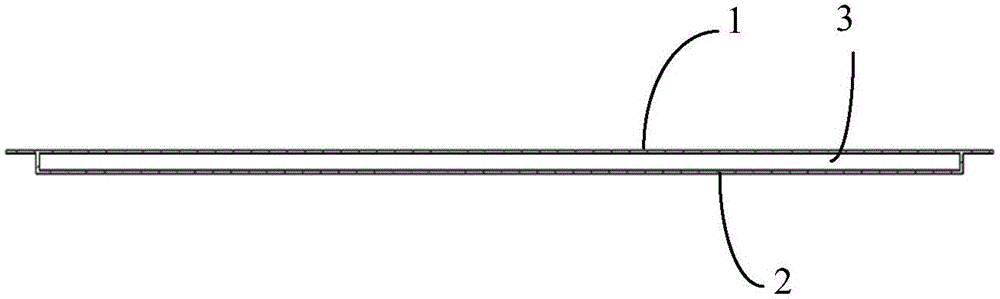

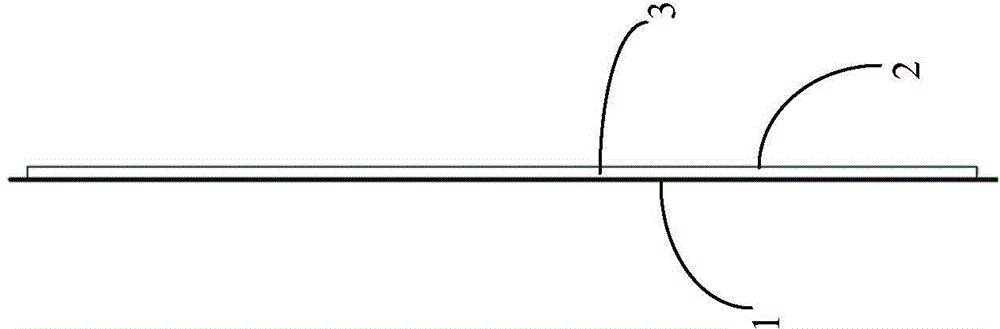

[0013] The above-mentioned features and advantages of the present invention can be better understood after reading the detailed description of the embodiments of the present disclosure in conjunction with the following drawings. In the drawings, components are not necessarily drawn to scale, and components with similar related properties or characteristics may have the same or similar reference numerals.

[0014] Figures 1A to 1D The structure of the preferred embodiment of the hollow door of the present invention is shown from different angles of view. See also Figures 1A to 1D , The hollow door of this embodiment includes a first panel 1 , a second panel 2 and a hollow layer 3 sandwiched between the first panel 1 and the second panel 2 . The hollow layer 3 can be filled with air, an inert gas, or an intermediate vacuum, all in order to ensure a good heat insulation effect.

[0015] Preferably, a metal mirror coating is covered on the first panel 1 , and a metal mirror coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com