Automatic silk reeling machine steam pipeline device and its control technology

A steam pipe and silk reeling locomotive head technology, applied in the field of locomotive threading, can solve problems such as difficult threading, small temperature difference, etc., and achieve the effect of improving accuracy, improving adaptability, and expanding stand capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

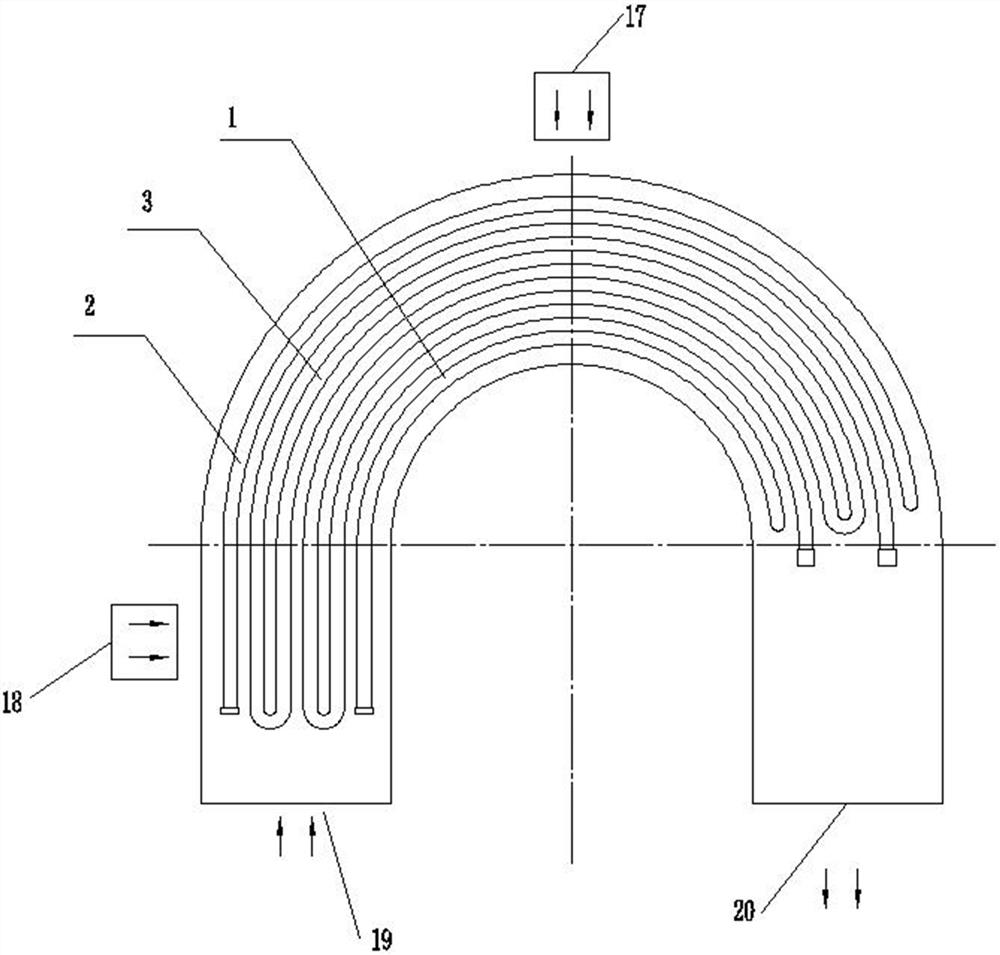

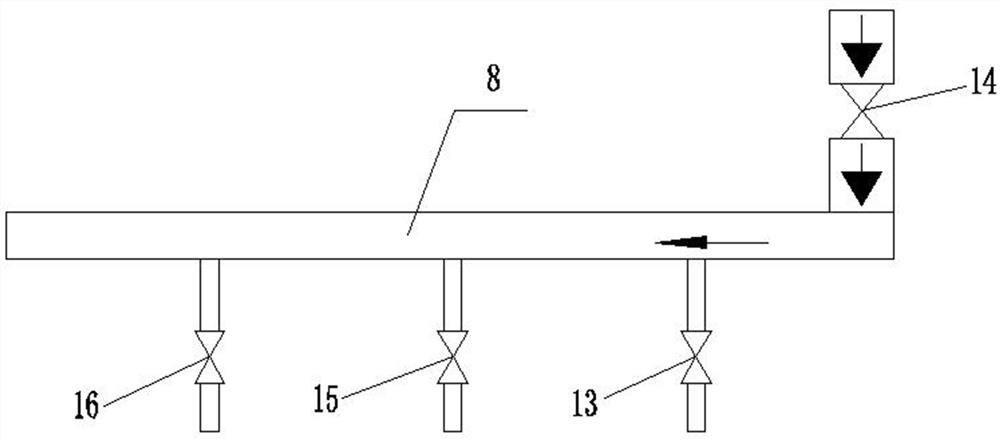

Embodiment 1

[0053] The invention proposes a steam pipeline device for an automatic silk reeling machine, which adopts a segmented design structure for controlling the total amount of steam, which solves the disadvantages of the prior art that the temperature difference between the high temperature zone and the low temperature zone is small and difficult to track, and can effectively Satisfied that the temperature of the high temperature zone of the Suoxu pot is in the required high temperature range, and the low temperature zone can also be in the required low temperature range, so that the Suoxu soup in the Suoxu pot can meet the temperature conditions of Suoxu, such as Figure 3-5 As shown, the following arrangement structure is adopted in particular: the inner hole pipe 1, the outer hole pipe 2, the blind pipe 3, the steam main pipe 8, the steam main valve 14, which are arranged at the Suoxu pot of the headstock, the inner hole pipe 1 and the outer hole pipe The orifice tubes 2 are comp...

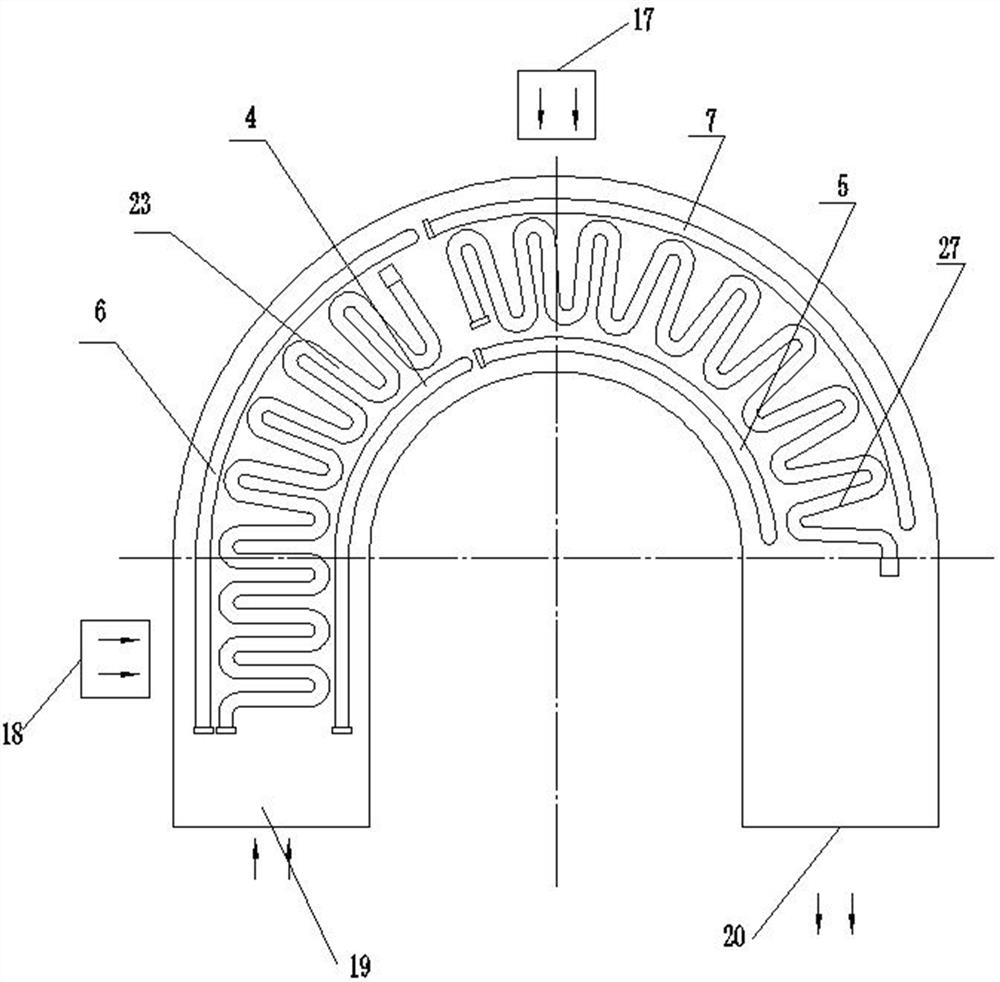

Embodiment 2

[0056] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the automatic silk reeling machine steam pipeline device of the present invention, such as Figure 3-5As shown, the following arrangement method is adopted in particular: the inner hole tube 1 is provided with the inner hole tube 4 of the high temperature temperature control part and the inner hole tube 5 of the low temperature temperature control part respectively connected with the steam main pipe 8, and the inner hole tube 4 of the high temperature temperature control part passes through The valve group of the high temperature temperature control part is connected with the steam main pipe, and the inner hole pipe 5 of the low temperature temperature control part is connected with the steam main pipe through the valve group of the low temperature temperature control part.

[0057] When designed and used, the inner hole tube 1 is composed of the inner hole tub...

Embodiment 3

[0059] This embodiment is further optimized on the basis of any of the above embodiments, further to better realize the automatic silk reeling machine steam pipeline device of the present invention, such as Figure 3-5 As shown, the following arrangement method is adopted in particular: the outer hole tube 2 is provided with the outer hole tube 6 of the high temperature temperature control part and the outer hole tube 7 of the low temperature temperature control part respectively connected with the steam main pipe 8, and the outer hole tube 7 of the high temperature temperature control part The pipe 6 is connected to the steam main pipe through the valve group of the high temperature temperature control part, and the outer hole pipe 7 of the low temperature temperature control part is connected to the steam main pipe through the valve group of the low temperature temperature control part.

[0060] When designed and used, the outer hole tube 2 is composed of the outer hole tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com