Constant temperature anaerobic kimchi fermentation device

A fermentation device and constant temperature technology, applied in the field of constant temperature anaerobic kimchi fermentation device, can solve the problems of unavailable fermentation liquid, long production cycle, measurement and monitoring, etc., achieve real-time monitoring of the fermentation process, facilitate operation, and avoid excessive temperature or too low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples, but the given examples are not intended to limit the present invention.

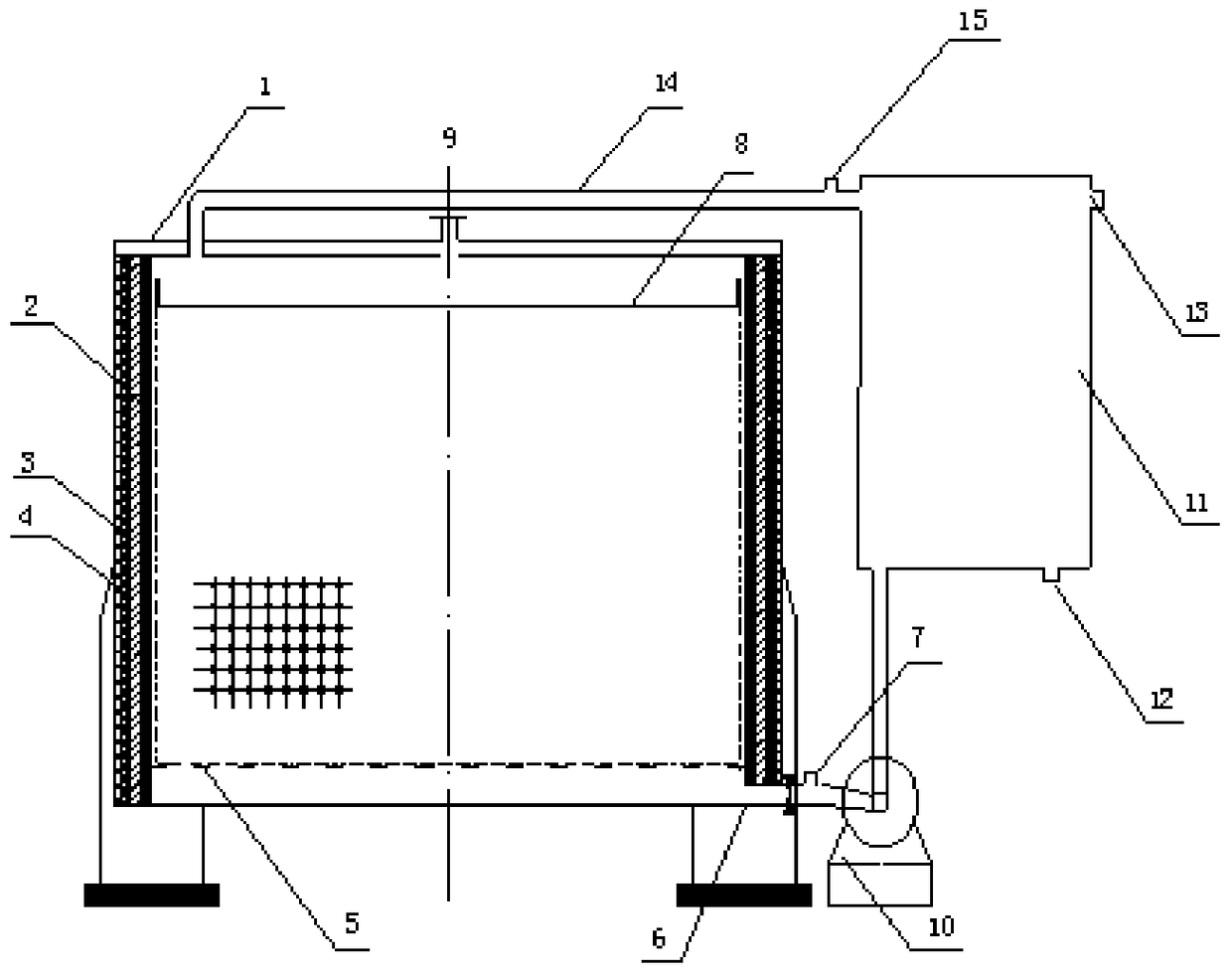

[0027] Such as figure 1 As shown, the embodiment of the present invention includes a cylinder body, the cylinder body is composed of an outer cylinder, an inner cylinder 8 and a cover body 1 and is a closed structure, the inner cylinder 8 communicates with the outer cylinder, and a circulating pump 10 connected thereto is also included And the heat exchanger 11, the circulating pump 10 communicates with the outer cylinder through the liquid outlet pipe 6, the liquid outlet pipe 6 is provided with a detection port A7, the heat exchanger 11 communicates with the cover body 1 through the fermentation liquid pipe 14, and the fermentation liquid pipe 14 is connected It is equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com