A New Industrial Fluidized Bed Reactor with Inorganic Thermal Superconducting Technology

A fluidized bed reactor and thermal superconducting technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of leakage fluidized bed heat transfer capacity, complex structure, poor temperature uniformity, etc., and achieve the elimination of local High temperature, large heat transfer capacity, and good temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

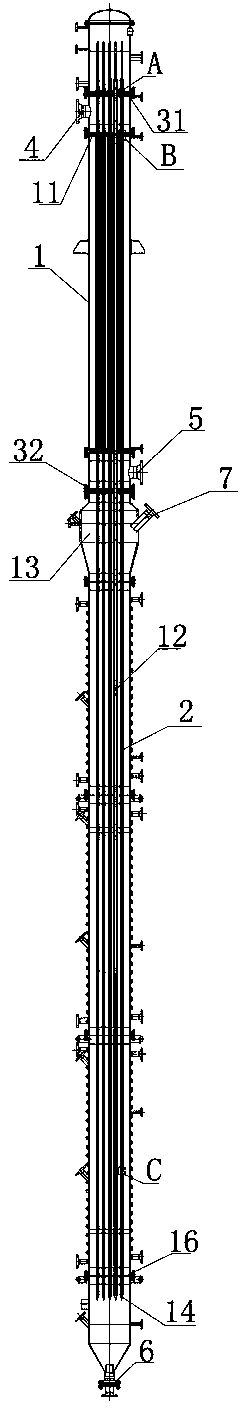

[0039] Such as Figure 1 to Figure 6 The fluidized bed shown includes a cylinder 1 and several inorganic thermal superconductors 2 arranged in the cylinder 1 .

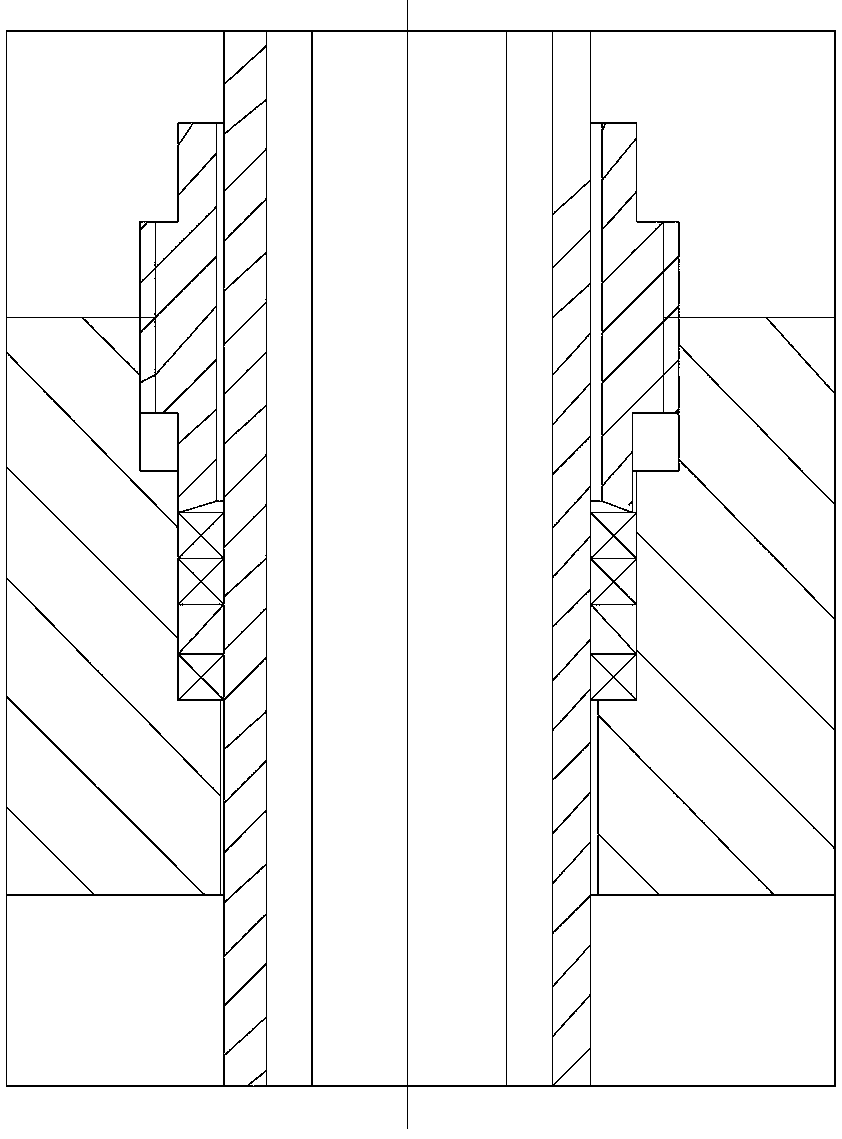

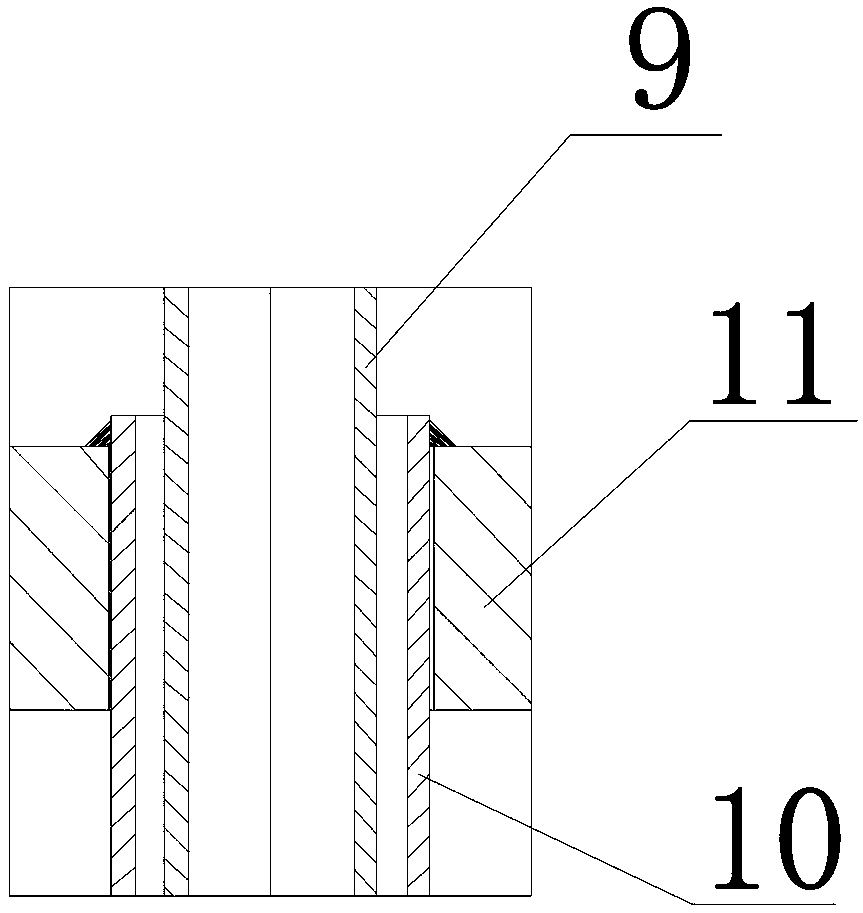

[0040] The cylinder body 1 is separated from top to bottom by an upper partition 31 and a lower partition 32 into a heat insulation area, a heat exchange area and a reaction area. The upper and lower parts of the heat exchange area are respectively provided with a refrigerant outlet 4 and a refrigerant inlet 5. The reaction area There are gas-solid phase inlets 6 and gas-solid phase outlets 7 at the lower and upper parts respectively. The preferred length of the heat insulation zone in this embodiment is about 600mm downward from the top of the cylinder. In this application, the upper partition 31, the lower partition 32 and the cylinder are fixed by welding, and the inorganic ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com