Diesel engine fuel oil system fault diagnosis method based on least square support vector machine

A technology of support vector machine and least squares, applied in the direction of internal combustion engine testing, etc., can solve the problems of less adjustable parameters of particle swarm and difficult algorithm convergence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The method for diagnosing the fuel system fault of a diesel engine based on the least squares support vector machine of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

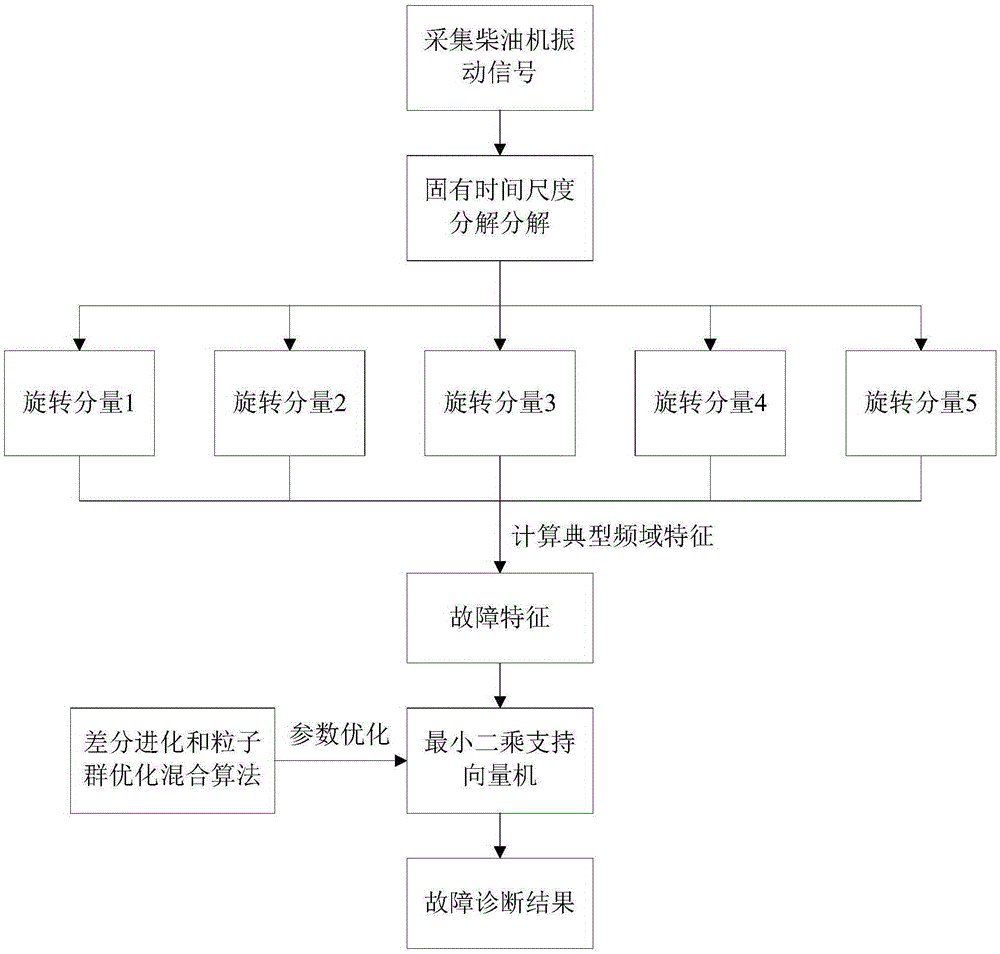

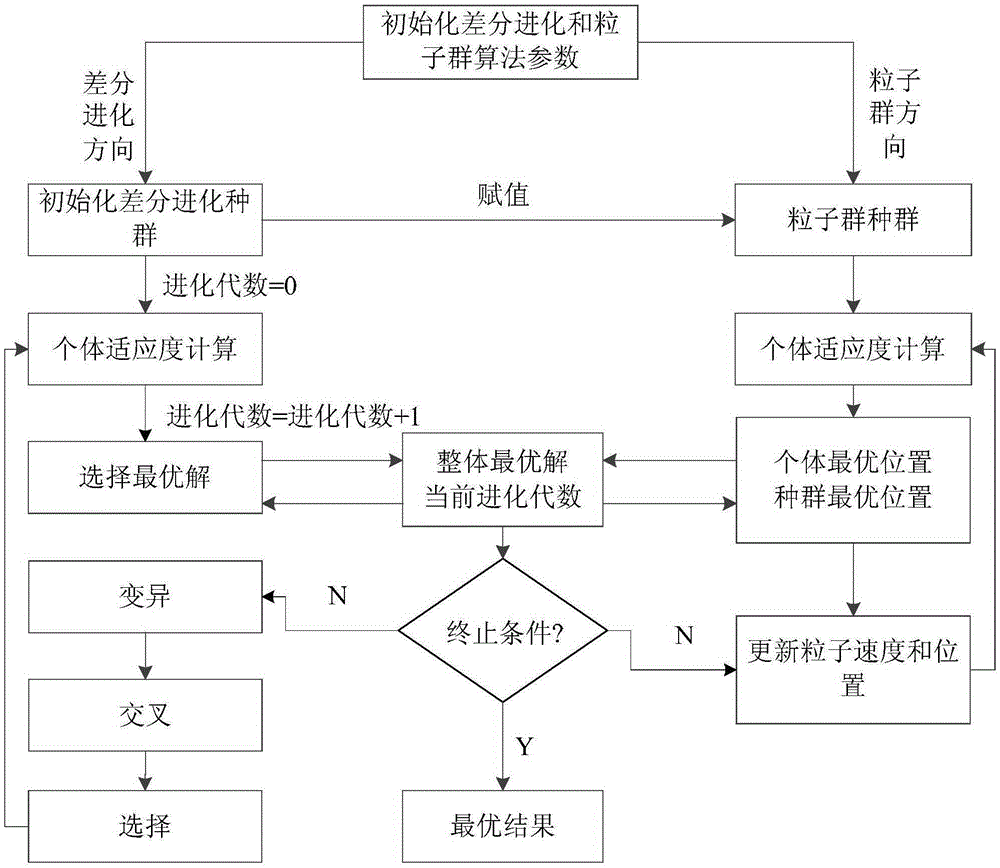

[0053] Such as figure 1 Shown, the diesel engine fuel system fault diagnosis method based on the least squares support vector machine of the present invention, comprises the following steps:

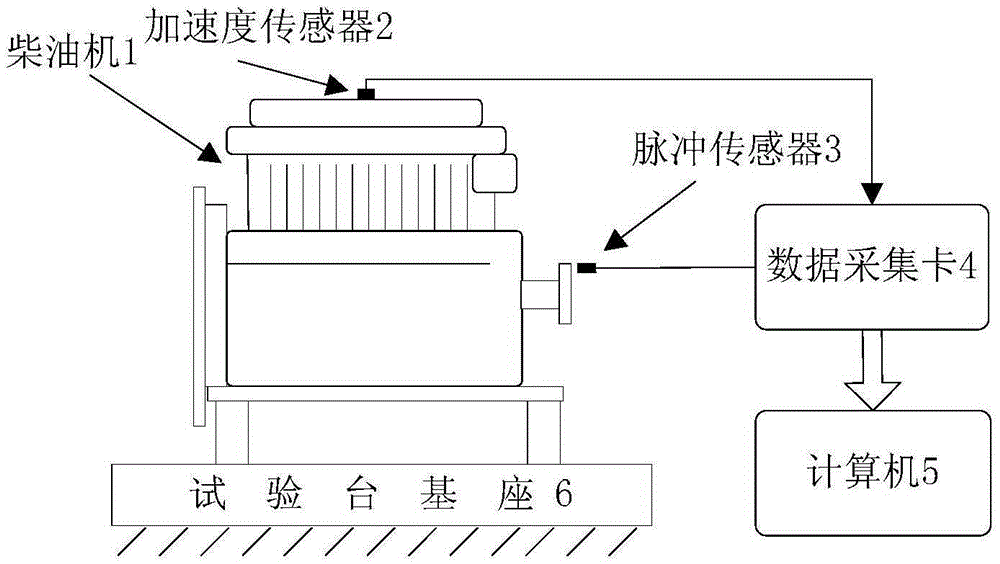

[0054] 1) Use the acceleration sensor to collect the vibration acceleration signal x(t) of the diesel engine under normal and various fault conditions;

[0055]2) Diesel engine vibration signals have strong non-stationary nonlinear characteristics, so signal processing methods based on signal stationarity assumptions such as Fourier transform are not suitable for processing diesel engine vibration signals. Intrinsic time scale decomposition is a new non-stationary signal analysis method, which can adaptively decompose multi-component signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com