Parallel power conversion control device

A technology of power conversion and control device, applied in the direction of regulating electric variables, control/regulating systems, instruments, etc., can solve problems such as affecting the tracking effect of the inverter, and achieve the effect of overcoming the poor effect of circulating current suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

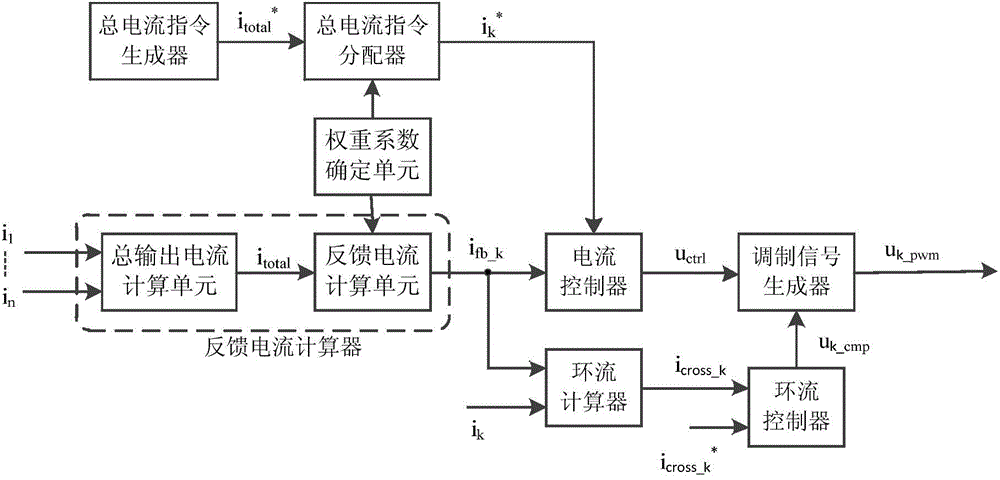

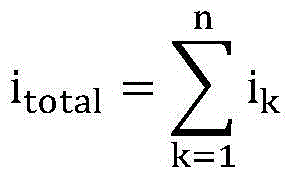

[0038] The structure of the parallel power conversion control device used in the parallel power conversion system composed of at least two power converters connected in parallel in the present invention is as follows: figure 1 As shown, it is mainly composed of a total current command generator, a weight coefficient determination unit, a total current command distributor, a current controller, a circulating current calculator, a circulating current controller, a modulation signal generator, and a feedback current calculator. The total current command generator is used to generate the total current command value that should be output by the parallel power conversion system; the weight coefficient determination unit is used to determine the proportion of the current of each power converter in the total output current of the parallel power conversion system, output Corresponding to the weight coefficient of the power converter; the total current command distributor is used to dist...

Embodiment 2

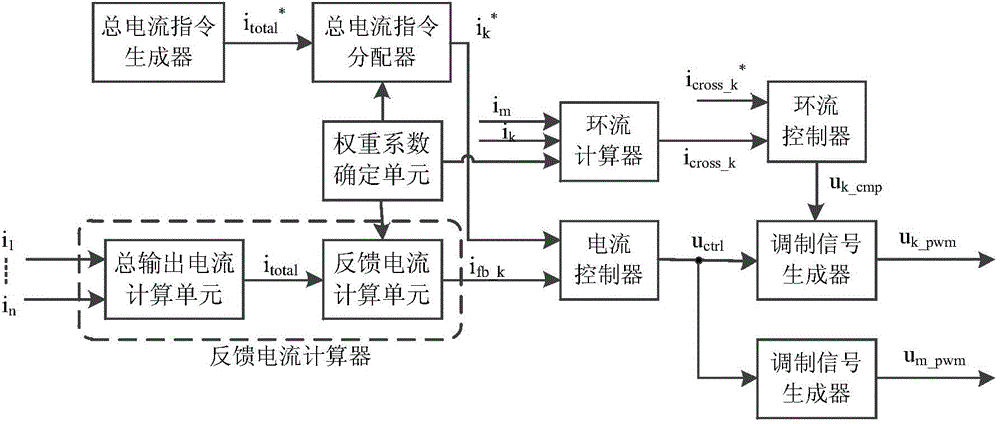

[0058] like figure 2 As shown, this embodiment is similar to Embodiment 1, and only the differences from Embodiment 1 will be described below.

[0059] In this embodiment, the parallel power conversion control device first selects the mth power converter as the reference power converter. For the control of any other non-reference power converter (such as the power converter numbered k, k≠m), the corresponding circulating current calculator calculates the circulating current of the kth power converter according to the following formula, i corss_k :

[0060] i corss_k = i k -(α k / α m )×i m Formula 5

[0061] Among them, i corss_k is the circulating current of the kth power converter, i k and i m are the current values of the kth and m power converters respectively, i fb_k is the current feedback value of the kth power converter, α k and alpha m are the weight coefficients of the kth and m power converters respectively, and m is the serial number of the reference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com