A biofiltration method for simultaneously removing NOx, SO2 and PM2.5 under an aerobic environment

A biological filtration and SO2 technology, applied in the direction of chemical instruments and methods, separation methods, combined devices, etc., can solve the problems of reduced activity, trouble, and reduced removal efficiency, so as to achieve less secondary pollution, overcome the inhibition of oxygen, and run The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Synthetic waste gas: NOx0.5mg / m 3 , SO 2 0.3mg / m 3 , O 2 3%, CO 2 18%. The average volume flow rate of exhaust gas is 10m 3 / h.

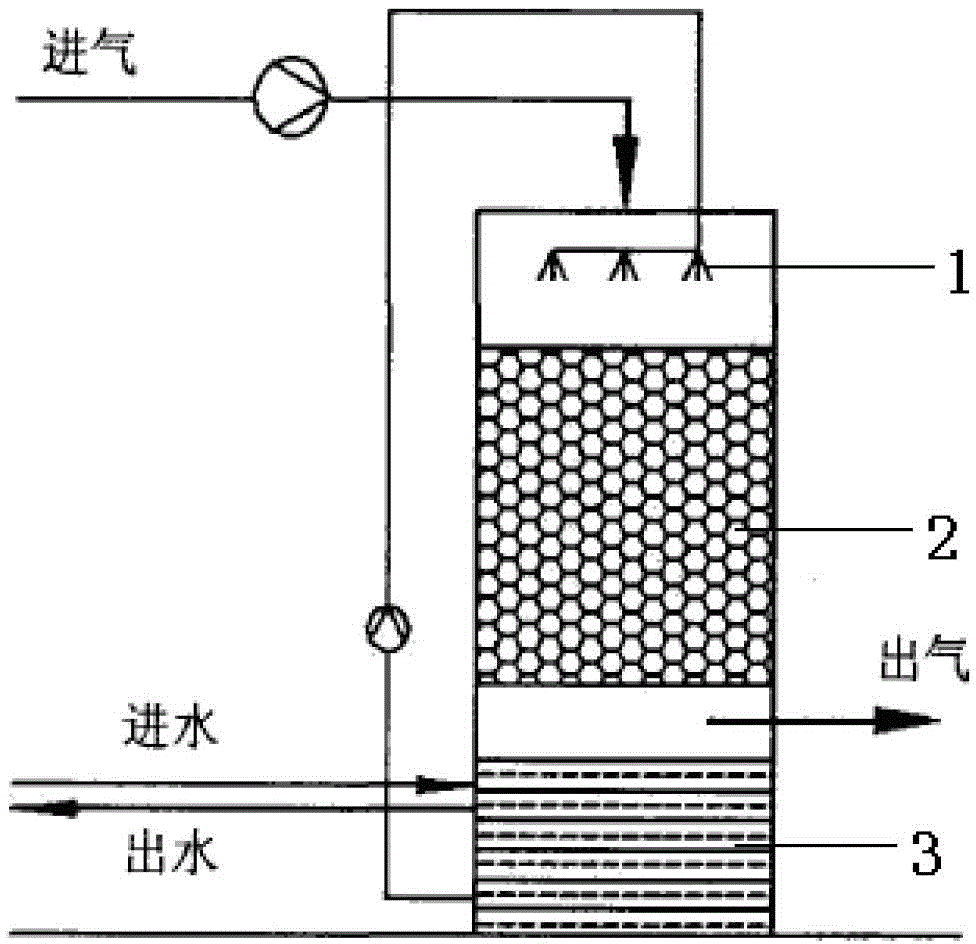

[0027] (1) Due to the low intake air volume and intake concentration, only one filler layer 2 is required. The filler is made of polypropylene multifaceted hollow spheres, the diameter of the filler is 25mm, the porosity reaches 0.81, and the density is 0.14g / cm 3 , the specific surface area is 50m 2 / m 3 , a distributor 1 is arranged above the filler.

[0028] (2) Inoculate the cultured composite bacteria on the filler, and regularly measure the waste gas treatment efficiency. After half a month of circulating the film, the net gas efficiency of the waste gas reaches 90%, and the film is successfully formed.

[0029] (3) The main components and proportions of circulating nutrient solution 3 are as follows: glucose 9g / L, NaCl 5g / L, phosphate buffer pH=6.8-7.2, MgSO 4 ·7H 2 O0.1g / L, trace element solution 2ml / L. Trace element rati...

Embodiment 2

[0031] The main components and concentration of exhaust gas from a small boiler: NOx90mg / m 3 , SO 2 60mg / m 3 , O 2 8.1%, CO 2 11.2%, PM 2.5 The content is 400μg / m 3 . The average volume flow rate of exhaust gas is 1762.5m 3 / h.

[0032] (1) According to the amount of gas to be treated, it is determined that the packing is stacked in two layers. The size of the biological trickling filter tower: the inner diameter is 2m, the height is 10m, and the effective volume is about 31.4m 3 .

[0033] (2) In the biological filter tower, there is a distributor above each layer of packing. The hanging film adopts the method of mixed culture of filler and culture medium, so that the microorganisms are well loaded on the surface of the filler, and then loaded into the packed tower. And hang the film for a period of time, so that the biofilm on the filler can adapt to the flue gas treatment environment.

[0034] (3) The main components and proportions of the circulating nutrient s...

Embodiment 3

[0037] Main components and concentrations of flue gas from a coal-fired power plant: NO400mg / m 3 , SO 2 120mg / m 3 , O 2 7.5%, CO 2 10.6%, PM 2.5 The content is 500μg / m 3 . Exhaust gas volume flow is about 10000m 3 / h. (1) According to the amount of gas to be treated, it is determined that the packing is stacked in three layers. The size of the biological trickling filter tower is 4m in inner diameter, 20m in height, and the effective volume is about 251.2m 3 .

[0038] (2) In the biological filter tower, there is a distributor above each layer of packing. The hanging film adopts the method of mixed culture of filler and culture medium, so that the microorganisms are well loaded on the surface of the filler, and then loaded into the packed tower. And hang the film for a period of time, so that the biofilm on the filler can adapt to the flue gas treatment environment.

[0039] (3) The main components and proportions of the circulating nutrient solution are as follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com