High-frequency core-shell structure micro-droplet ejection device

A technology of core-shell structure and spraying device, which is applied in the direction of liquid spraying device, spraying device, electrostatic spraying device, etc., can solve the problems of limiting the spray rate of micro-droplet printing, different droplet spraying conditions, and difficult control, etc., to achieve Effects of overcoming interference and inhibition, promoting flow, and increasing injection frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

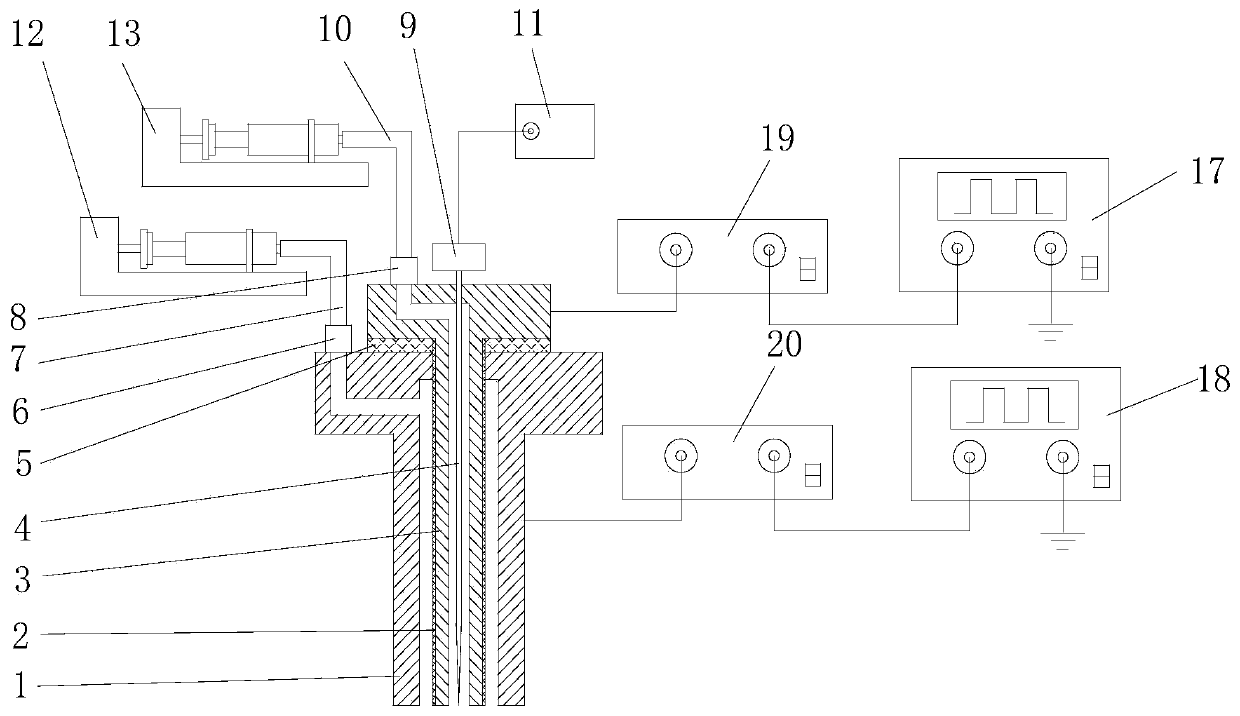

Embodiment 1

[0025] see figure 1, a high-frequency core-shell micro-droplet ejection device in this embodiment, comprising a nozzle sheath layer 1, a nozzle inner layer insulating layer 2, a nozzle inner layer 3, a needle core 4, an insulating gasket 5, and a sheath layer liquid inlet interface 6. Sheath layer liquid inlet conduit 7, inner layer liquid inlet transfer port 8, needle core vibration block 9, inner layer liquid inlet catheter 10, needle core vibration controller 11, sheath layer controllable liquid supply device 12, inner layer controllable Liquid supply device 13, inner layer waveform programmable power supply 17, sheath layer waveform programmable power supply 18, sheath layer waveform high-voltage amplifier 19, inner layer waveform high-voltage amplifier 20, the nozzle sheath 1 passes through the sheath layer waveform high-voltage amplifier 19 and the sheath The layer waveform programmable power supply 18 is electrically connected, and the arbitrary waveform output by the s...

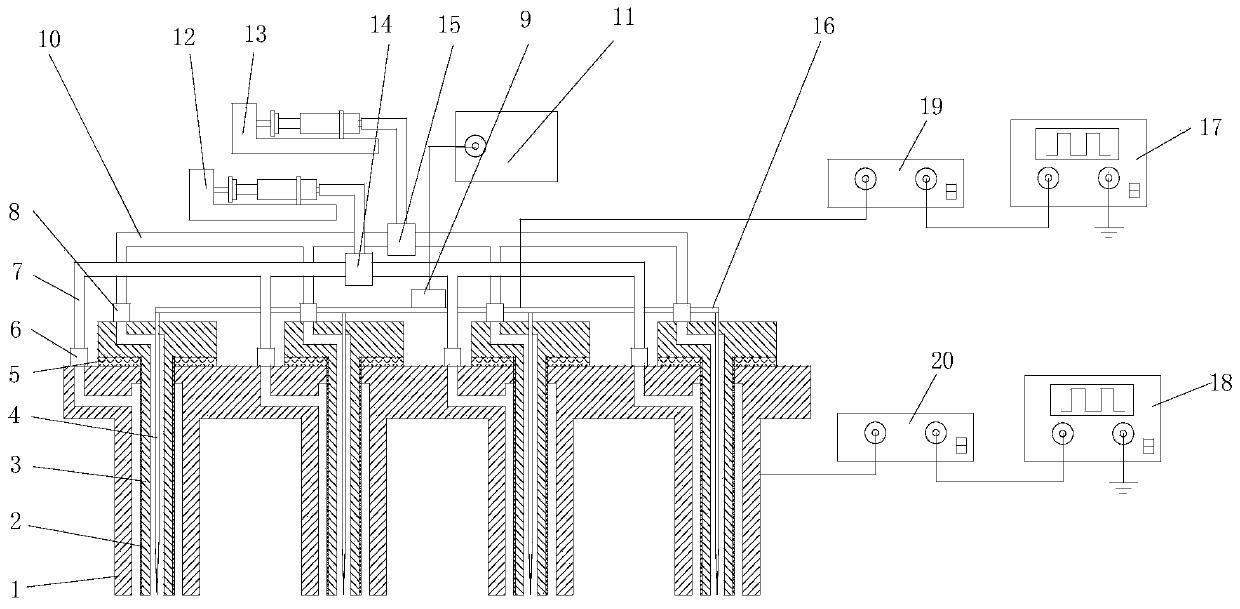

Embodiment 2

[0030] see figure 2 , a high-frequency core-shell micro-droplet ejection device in this embodiment, comprising a nozzle sheath layer 1, a nozzle inner layer insulating layer 2, a nozzle inner layer 3, a needle core 4, an insulating gasket 5, and a sheath layer liquid inlet interface 6. Sheath layer liquid inlet conduit 7, inner layer liquid inlet transfer port 8, needle core vibration block 9, inner layer liquid inlet catheter 10, needle core vibration controller 11, sheath layer controllable liquid supply device 12, inner layer controllable Liquid supply device 13, sheath layer liquid inlet catheter connector 14, inner layer liquid inlet catheter connector 15, nozzle inner layer conductive plate 16, inner layer waveform programmable power supply 17, sheath layer waveform programmable power supply 18, sheath layer waveform high voltage Amplifier 19, inner waveform high-voltage amplifier 20, the nozzle sheath 1 is electrically connected to the sheath waveform programmable powe...

Embodiment 3

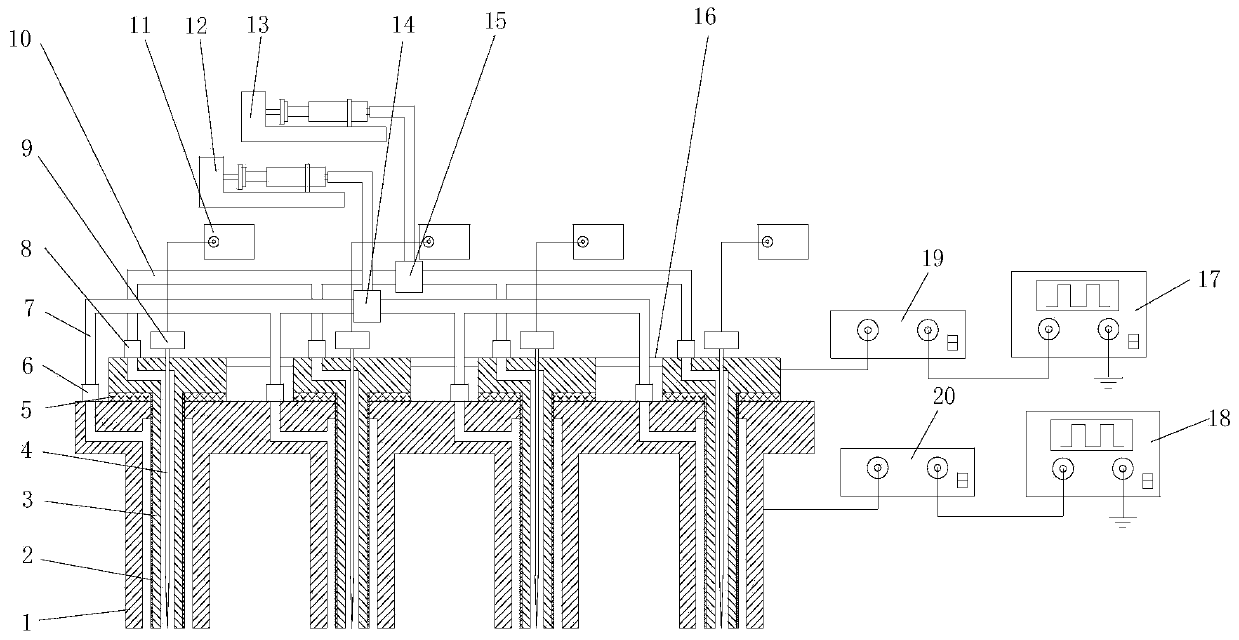

[0037] see image 3 , this example and figure 2 The structure of the embodiment is basically the same, the difference is that the number of needle cores 4 matches the number of nozzle inner layers 3, each needle core 4 is connected to a needle core vibration block 9, and the number of needle core 4 vibrators is multiple , a plurality of needle core vibration controllers 11 are respectively connected to a plurality of needle core vibration blocks 9 .

[0038] During the use of this embodiment, the sheath layer solution and the inner layer solution flow through the sheath layer liquid inlet conduit 7 and the inner layer liquid inlet conduit 10 respectively from the sheath layer controllable liquid supply device 12 and the inner layer layer controllable liquid supply device 13 The sheath liquid inlet transfer port 6 and the inner layer liquid inlet transfer port 8 realize the uniform liquid supply to the sheath layer 1 and the inner layer 3 of the nozzles of multiple coaxial no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com