Vector light field regulation and control optical fiber based on nanometer grating array

A nano-grating and vector light field technology, applied in the direction of grating fiber, cladding fiber, optical waveguide light guide, etc., can solve the problems of multiple vector light field mode coupling crosstalk, etc., and achieve small size, high stability and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

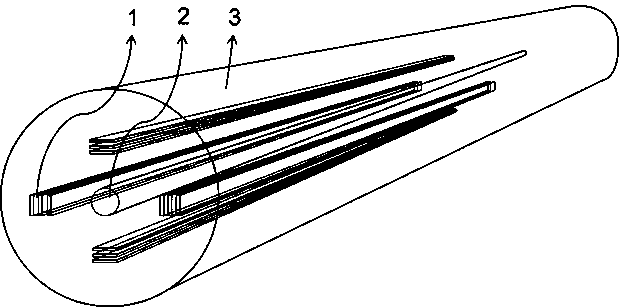

[0029] Embodiment one: see attached figure 1 , the present invention is based on a nano-grating array vector light field control optical fiber, including an optical fiber (3), characterized in that: the optical fiber (3) includes a fiber core (2) and a nano-grating array implanted near the core ( 1).

Embodiment 2

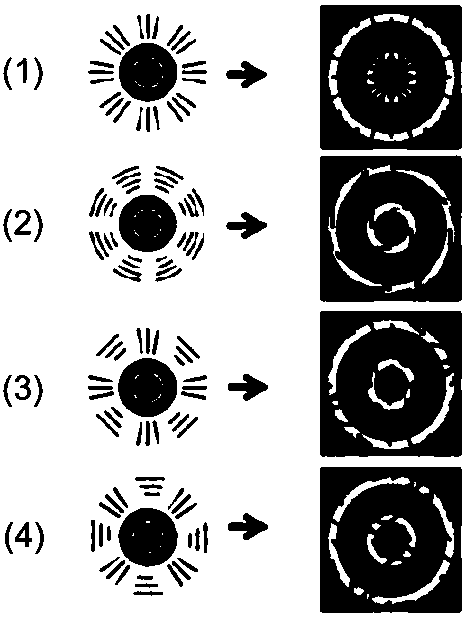

[0030] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows: the optical fiber (3) is a few-mode optical fiber, or a multi-mode optical fiber, or a hollow-core optical fiber, or a polarization-maintaining optical fiber, or a ring optical fiber, Or rare earth doped fiber, or large mode field fiber, or double-clad fiber, or photonic crystal structure fiber. The nano-grating array (1) is a sub-wavelength periodic structure induced and formed inside the optical fiber (3) by femtosecond laser direct writing technology, and its period, grating arrangement direction, birefringence intensity characteristics and scattering characteristics are passed through femtosecond Laser parameters and direct write process parameters for precise control. The normal line of the grating surface of the nano-grating array (1) is perpendicular to the direction of the fiber core (2). The nano grating array (1) is distributed in the cladding around ...

Embodiment 3

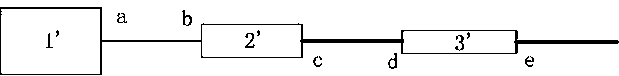

[0031] Embodiment three: see attached image 3 , which shows the device diagram of the present invention based on vector light field control fiber combined with high-order mode generator to output vector light field. Laser light source (1'), high-order mode generator (2') and optical fiber with vector light field control function (3') are used which are fused in sequence.

[0032] The laser light source (1') is a semiconductor laser with adjustable power, or a solid-state laser, or a fiber laser. It is broadband, or narrow linewidth. It can be continuous, or pulsed.

[0033] The optical fiber (3') with vector light field control function is formed by directly writing nano-grating arrays in the optical fiber with femtosecond laser pulses, see the attached figure 1 . The specific manufacturing process is as follows: straighten the optical fiber and fix the two ends with a rotatable clamp, and place it on a femtosecond laser three-dimensional precision processing platform. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com