Control tooling and method for spinning deformation temperature field of large-sized high rare earth magnesium alloy barrel-shaped piece

A spinning deformation, high rare earth technology, used in manufacturing tools, metal processing equipment, forming tools, etc., can solve the problems of uneven temperature field, poor plastic deformation ability, large temperature gradient, etc., to improve the forming quality and forming accuracy. , to ensure the uniformity of the temperature field and the effect of uniform temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109]In this embodiment, the large-sized high-performance high-rare-earth magnesium alloy cylindrical piece is Mg-Y-Nd-Zr series rare-earth magnesium alloy, and its rare earth content is 12%. The inner diameter of the cylindrical piece is Ф750mm, the height is 650mm, and the wall thickness is 4mm. The following is a specific process of a large-size high-rare-earth magnesium alloy cylindrical part spinning deformation temperature field control tool and control method:

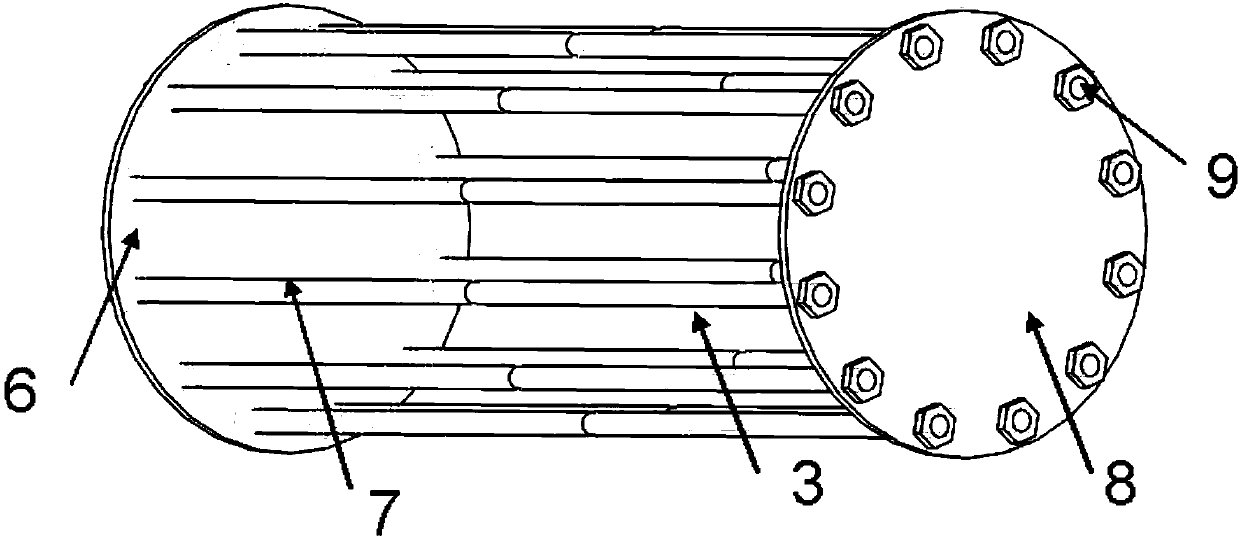

[0110] Tooling for controlling the temperature field of spinning deformation of large-sized high rare earth magnesium alloy cylindrical parts, the tooling includes spinning die 1, radiation heating device 3, compression bolt 4 and tail top 5; spinning die 1, radiation heating device 3, pressing The materials of the tightening bolt 4 and the tail top 5 are all A3 steel;

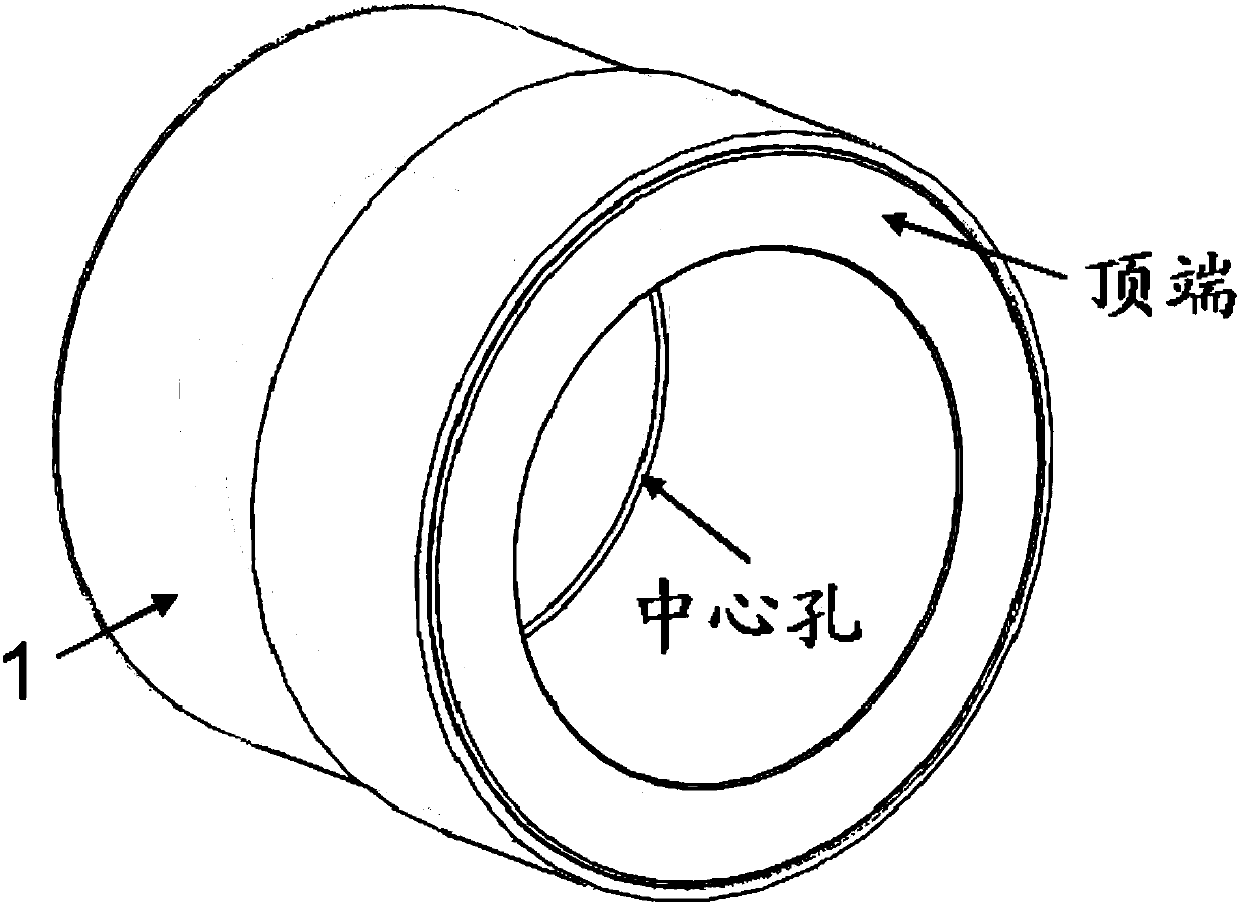

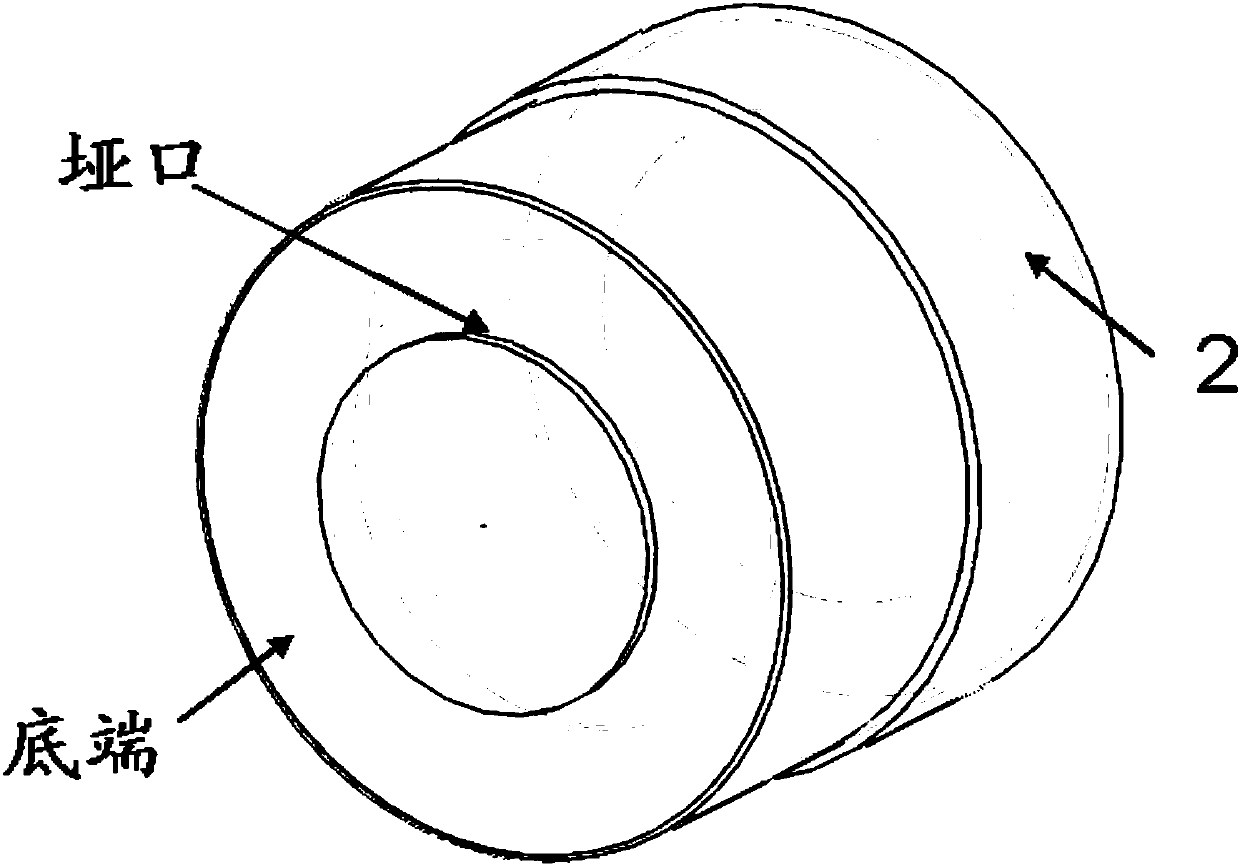

[0111] The spinning die 1 is a first hollow cylinder with a central hole, the bottom end of the first hollow cylinder has a mouth, and the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com