Preparation method of electrochemical battery

An electrochemical and battery technology, applied in the field of energy storage, can solve the problems of occupying production costs, time-consuming, and complicated procedures, and achieve the effect of convenient low-cost production, simple and reliable procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

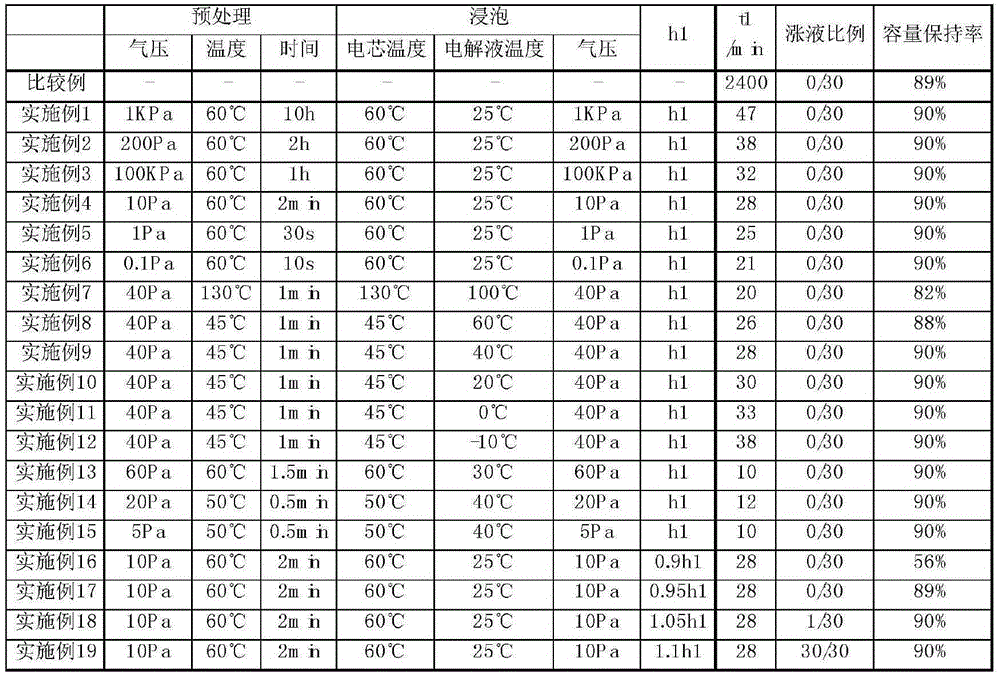

Examples

Embodiment 1

[0030] Embodiment 1, different from Comparative Example 1, this embodiment comprises the following steps:

[0031] Cell preparation: Wind the positive electrode sheet, separator, and negative electrode sheet to obtain a bare cell, and then place it in a drying oven with the furnace temperature set at 80°C and preheat with ventilation; when the cell is preheated to 78°C (cell dry When the temperature is required), vacuumize the furnace to 4kpa, and keep the temperature in the furnace at 80°C for drying; when the water content inside the cell is lower than 200ppm, complete the drying;

[0032] Pretreatment: Vacuumize the dried cells to be liquid-filled for 10 hours in an environment of 1000 Pa, and keep the temperature of the cells at 60°C to obtain soaked bare cells;

[0033] Soaking: keep the vacuum, put the bare cell at 60°C in the electrolyte at 25°C, so that the bare cell is sealed by the electrolyte, and then soak until the electrolyte fully infiltrates the diaphragm;

[...

Embodiment 2

[0037] Embodiment 2, different from Embodiment 1, this embodiment includes the following steps:

[0038] Pretreatment: Vacuumize the dried cells to be liquid-filled for 2 hours in an environment of 200 Pa, and keep the temperature of the cells at 60°C to obtain soaked bare cells;

[0039] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0040] Embodiment 3, different from Embodiment 1, this embodiment includes the following steps:

[0041] Pretreatment: Vacuumize the dried cells to be liquid-filled in an environment of 100 Pa for 1 hour, and keep the temperature of the cells at 60°C to obtain soaked bare cells;

[0042] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com