Improved heating element

A heating element and heating element technology, applied in the direction of heating element material, heating element shape, etc., can solve problems such as limiting the scope of use and not meeting the needs of manufacturers, and achieve the effects of wide application range, reasonable structure, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

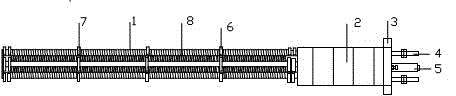

[0012] Such as figure 1 As shown, an improved heating element of the present invention includes a heating element, a straight tube casing 1 arranged outside the heating element for sealing and protecting the heating element, and a heat preservation section 2 arranged behind the heating element. One end of the casing 1 is The closed end, the other end is an open end, and a flange 3 is provided at the open end. The heating element includes two electrode lead-out rods 4 protruding from the shell, a thermocouple 5, multiple resistance wires 8 connected in series, and multiple resistance wires 8 along the shell. 1 The ceramic collar 6 is evenly arranged in the axial direction, and the resistance wire 8 is a high-resistance electrothermal alloy coiled into a spiral shape. The resistance wire 8 is designed to be coiled into a spiral shape. On the one hand, it can increase the surface area of the resistance wire and reduce the load on the surface of the resistance wire. It can be ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com