Technology for processing honeysuckle flower herbal tea

A honeysuckle herbal tea and processing technology technology, applied in the direction of tea substitutes, etc., can solve the problems of restricting the development of herbal tea, affecting the quality of products, and the quality of the extract being not qualified, and achieving the effect of expanding the scope of use, solving quality problems, and solving frequent precipitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

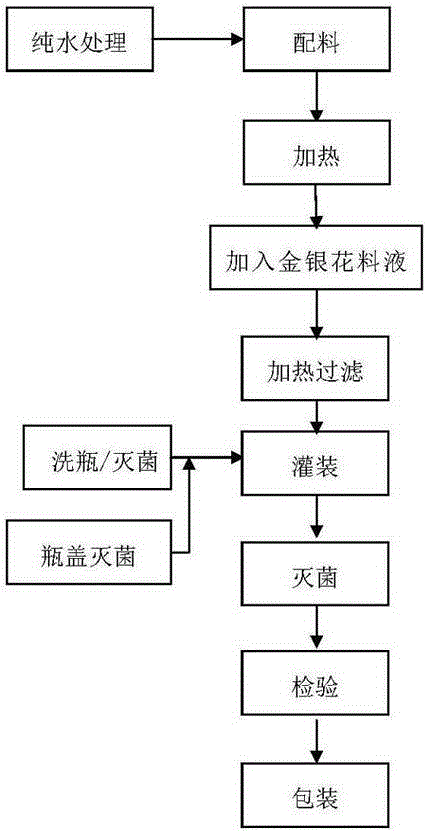

Method used

Image

Examples

Embodiment 1

[0026] Preparation before production: According to the standard procedure, 30 minutes before processing, the workshop is sterilized by ultraviolet light for 12 hours; after the workshop is sterilized, the filling machine and pipelines are cleaned, and then rinsed and disinfected with about 0.2MPa steam for about 15 minutes; After washing hands and disinfecting personnel, they enter their respective positions.

[0027] Ingredients: According to the formula, add 350kg of filtered water and 35kg of rock sugar into the cooking pot, turn on the steam and heat to 102°C, and filter after the sugar in the pot is completely dissolved; pump the above filtrate into the pot that has been pre-added with 150kg of distilled honeysuckle extract. In the mixing tank, turn on the mixer to fully mix the filtrate.

[0028] Treatment of feed liquid: add diatomite accounting for 0.04% of the feed amount to the mixed feed liquid, and circulate and filter through the plate and frame until the filtrate...

Embodiment 2

[0031] Preparation before production: According to the standard procedure, 30 minutes before processing, the workshop is sterilized by ultraviolet light for 12 hours; after the workshop is sterilized, the filling machine and pipelines are cleaned, and then rinsed and disinfected with about 0.2MPa steam for about 15 minutes; After washing hands and disinfecting personnel, they enter their respective positions.

[0032] Ingredients: According to the recipe, add 350kg of filtered water and 35kg of rock sugar to the cooking pot, turn on the steam and heat to 98°C, and filter after the sugar in the pot is completely dissolved; pump the above filtrate into the pot that has been pre-added with 150kg of distilled honeysuckle extract. In the mixing tank, turn on the mixer to fully mix the filtrate.

[0033] Treatment of feed liquid: add 0.04% diatomite to the mixed feed liquid, filter through plate and frame circulation until the filtrate is clear, transparent and bright, then heat to ...

Embodiment 3

[0036] Preparation before production: According to the standard procedure, 30 minutes before processing, the workshop is sterilized by ultraviolet light for 12 hours; after the workshop is sterilized, the filling machine and pipelines are cleaned, and then rinsed and disinfected with about 0.2MPa steam for about 15 minutes; After washing hands and disinfecting personnel, they enter their respective positions.

[0037] Ingredients: According to the recipe, add 350kg of filtered water and 35kg of rock sugar into the cooking pot, turn on the steam and heat to 100°C, and filter after the sugar in the pot is completely dissolved; pump the above filtrate into the pot that has been pre-added with 150kg of distilled honeysuckle extract. In the mixing tank, turn on the mixer to fully mix the filtrate.

[0038] Treatment of feed liquid: add 0.04% diatomite to the mixed feed liquid, filter through plate and frame circulation until the filtrate is clear, transparent and bright, then heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com