Aircraft interior honeycomb panel flying cutting tooling

A technology of honeycomb panel and interior decoration, which is applied in the field of fly-cutting tooling of aircraft interior decoration honeycomb panel, which can solve the problems of increased work cost, extended work cycle, surface damage of upper and lower wall panels, etc., and achieves improved processing quality, convenient and simple operation, and reduced The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

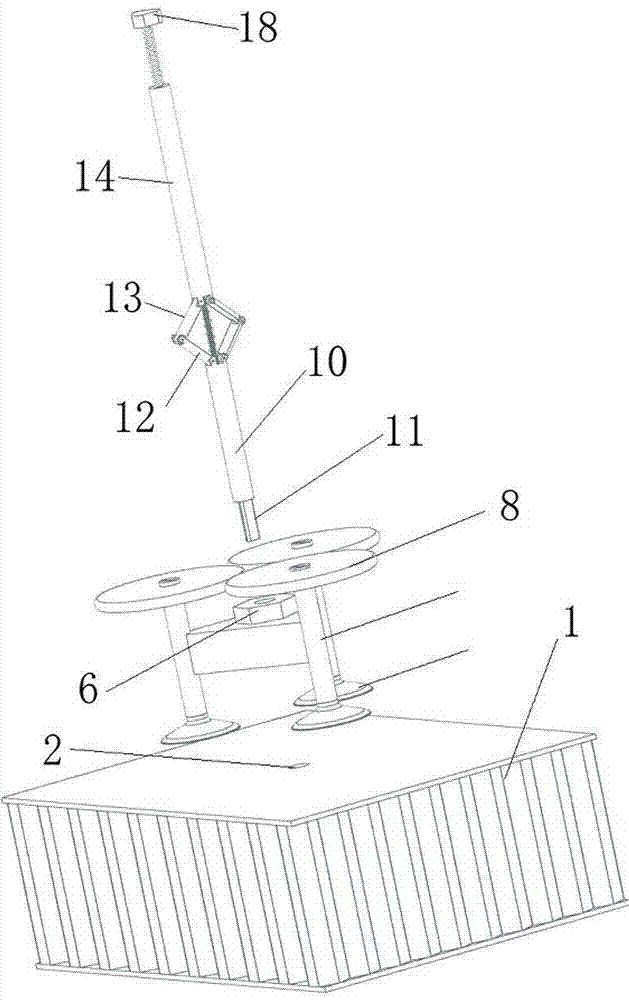

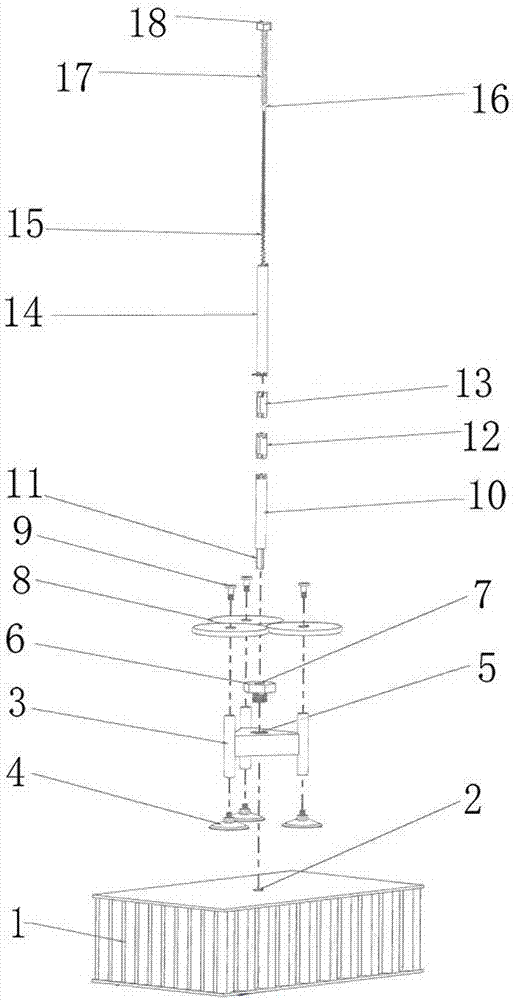

[0024] Attached below figure 1 , attached figure 2 The present invention will be further described.

[0025] A flying cutting tool for aircraft interior honeycomb panels, comprising: a honeycomb panel 1, a through hole 2 is vertically arranged inside; a driving rod 10 at the lower end, the outer diameter of which is smaller than the inner diameter of the through hole 2, and a triangular prism-shaped Pneumatic drill connecting rod 11; upper end drive rod 14, its outer diameter is less than the inner diameter of through hole 2; two upper cutting pieces 13 and two lower cutting pieces 12, which are semi-cylindrical respectively, and two upper cutting pieces 13, whose upper ends are hingedly mounted on The lower end of the upper drive rod 14, two lower cutting pieces 13, the lower ends of which are hingedly mounted on the upper end of the lower driving rod 10, the lower end of the upper cutting piece 13 and the upper end of the lower cutting piece 13 on the same side are hingedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com