Glass conveying device

A conveying device, glass technology, applied in the direction of conveyor objects, transportation and packaging, loading/unloading, etc., can solve problems such as personal injury, glass damage, and reduced conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

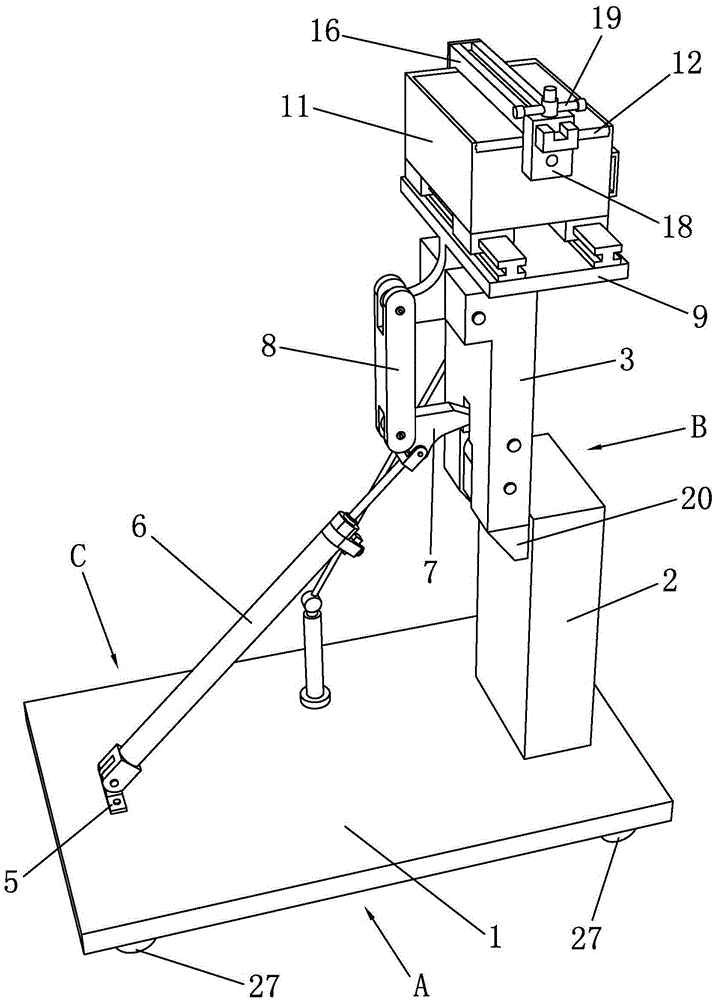

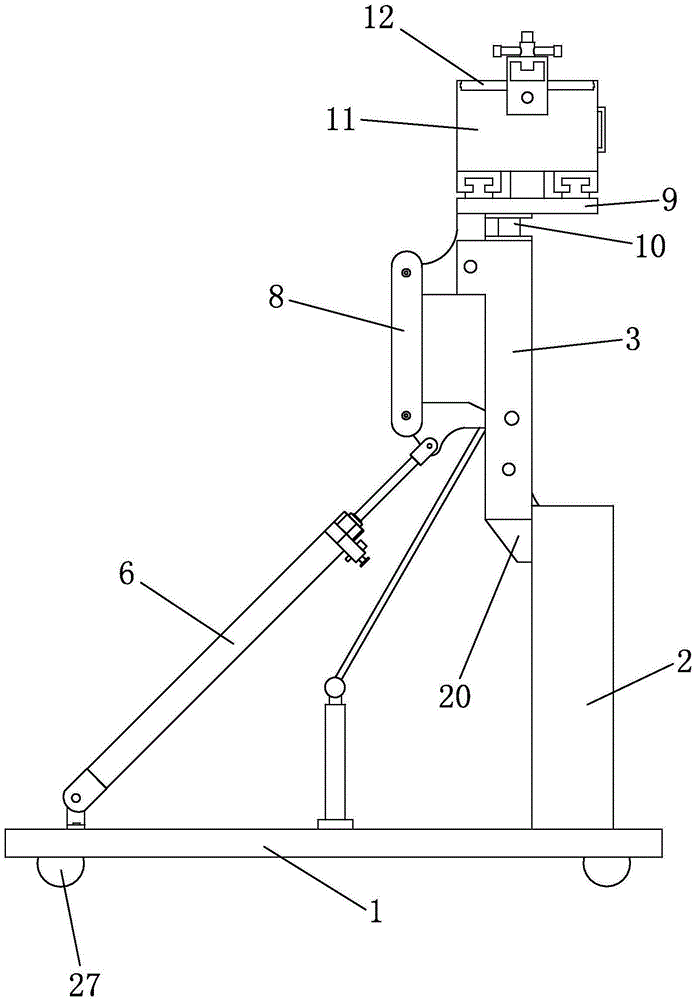

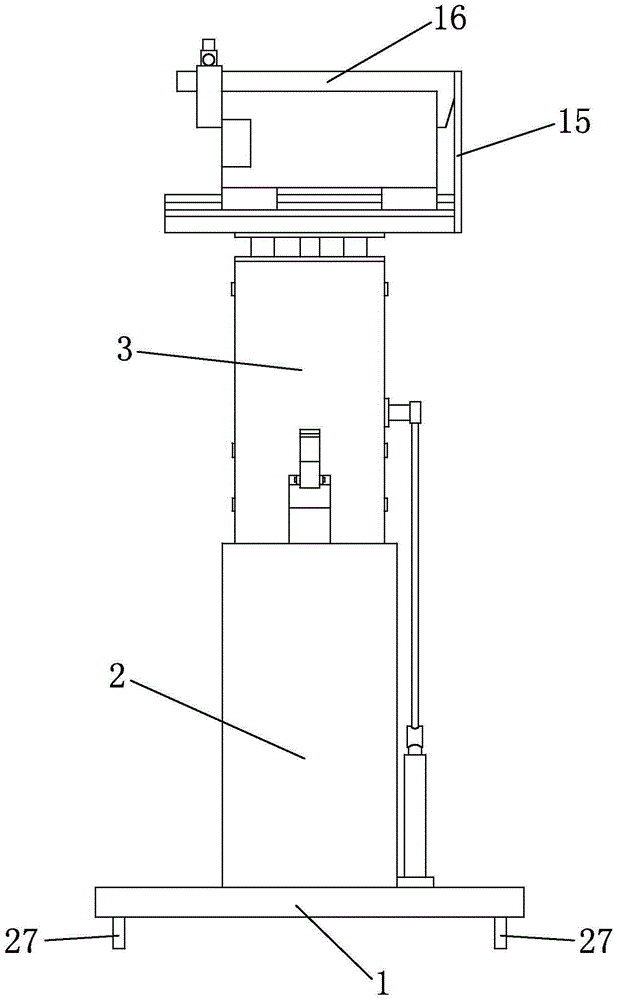

[0029] Such as Figure 1 to Figure 8 Shown is a glass conveying device of the present invention, including a base 1, the base 1 is a steel plate, and when installing components, installation holes should be reserved. The bottom of the base 1 is provided with a roller 27. The rolling of the roller 27 can adjust the distance between the glass conveying device and the truck, which is convenient for loading and unloading glass. In order to prevent the glass conveying device from rolling during conveying, a brake is generally installed on one side of the roller 27 piece.

[0030] The base 1 is provided with a supporting column 2, and the supporting column 2 is rotatably connected with a rotating arm 3. The bottom of the rotating arm 3 is provided with a contact block 20, which is in a triangular shape. When the rotating arm 3 transports glass, the rotating arm 3 3 Rotate on the supporting column 2, when the rotating arm 3 turns to the vertical state, one end of the contact stopper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com