Control system and control method for impressed current cathodic protection

A control method and cathodic protection technology, which is applied in the field of forced current cathodic protection control system, can solve the problems of unadjustable power supply, uncertain maintenance cycle, difficult maintenance, etc., and achieve good inner tank protection effect and wide water quality range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

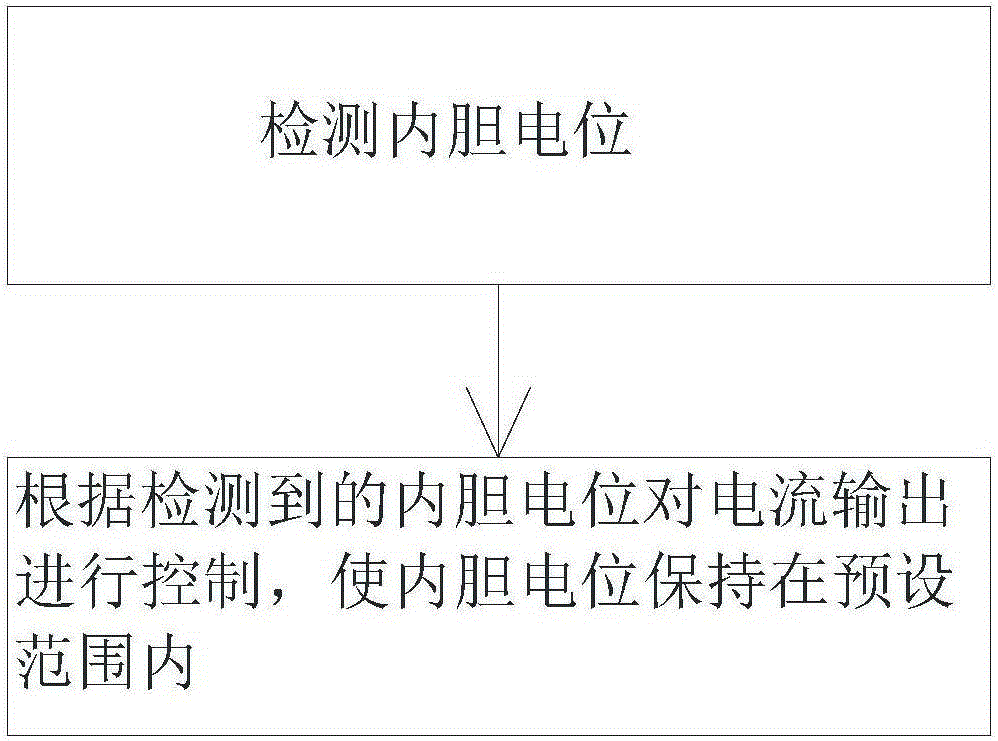

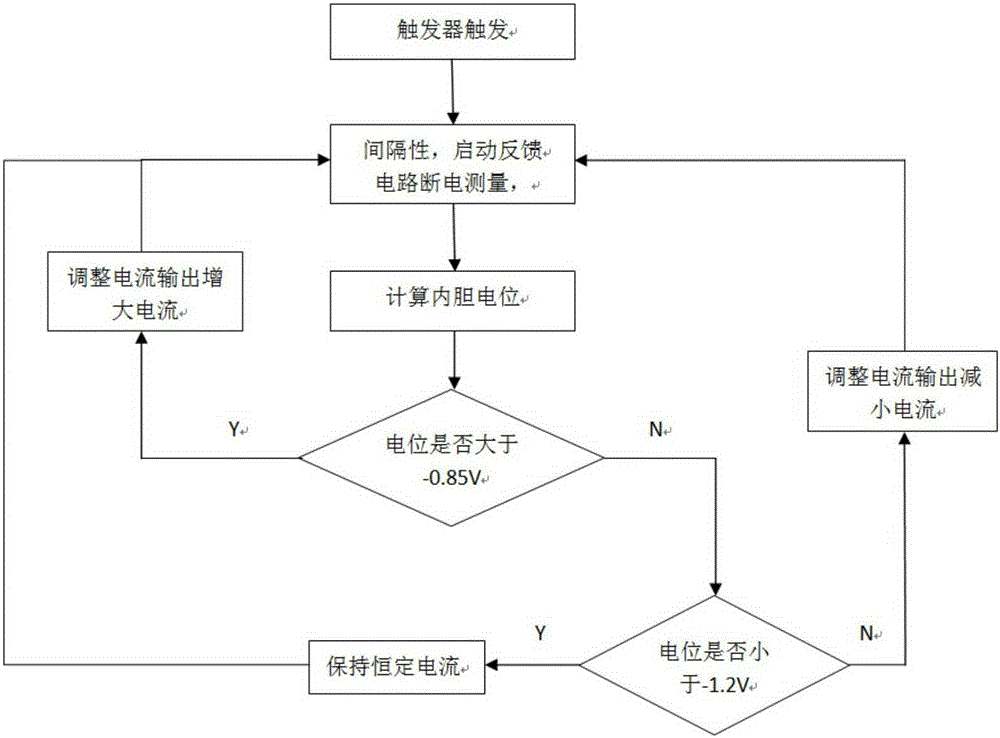

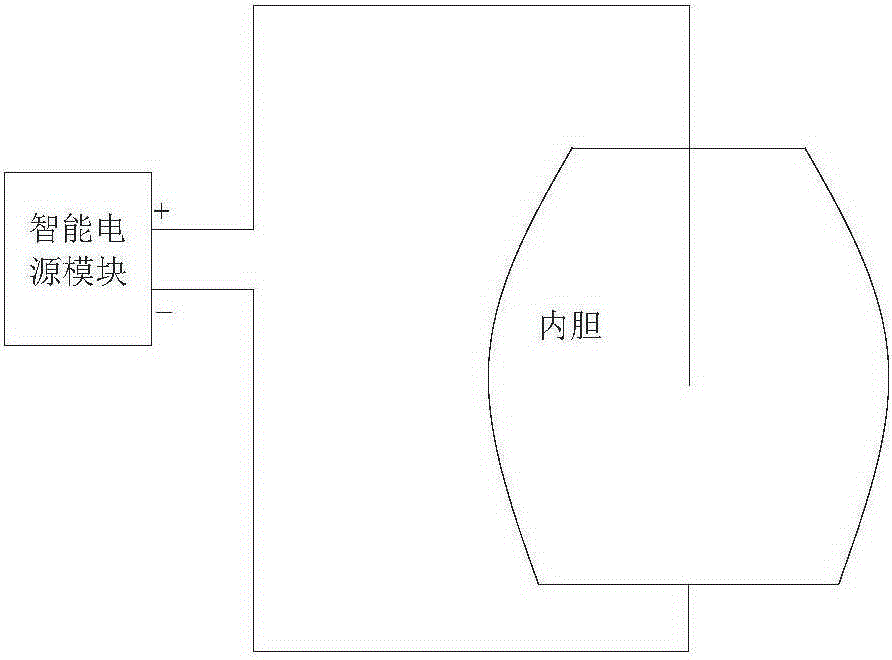

[0022] see figure 1 with figure 2 As shown, according to the embodiment of the present invention, the control method of forced current cathodic protection includes: detecting the potential of the inner tank; controlling the current output according to the detected potential of the inner tank to keep the potential of the inner tank within a preset range.

[0023] The embodiment of the present invention detects and obtains the current potential of the inner tank in real time, and controls and adjusts the current output to the inner tank based on this, thereby adjusting the potential of the inner tank, and the potential of the inner tank can be adjusted according to the actual working environment. Dynamic and real-time adjustment is carried out so that the potential of the liner can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com