Filter membrane equipment adopting self-coupling mounting

A kind of equipment and membrane technology, which is applied in the field of self-dual installation membrane membrane equipment, can solve the problems that the membrane unit cannot be separated from the sewage, the microorganisms cannot grow, and the chemical regeneration cleaning is inconvenient, so as to achieve convenient off-line regeneration cleaning and emergency treatment powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

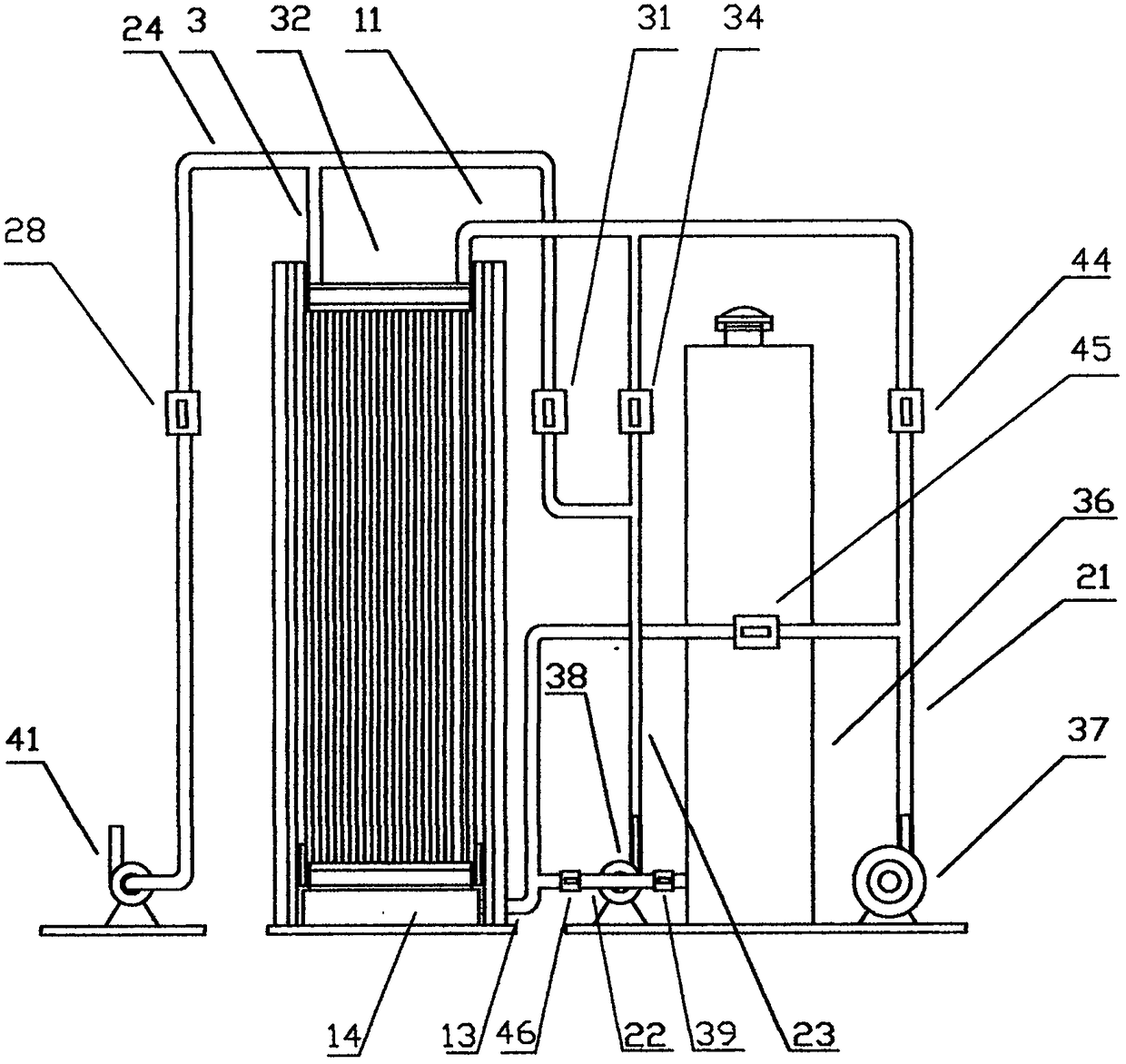

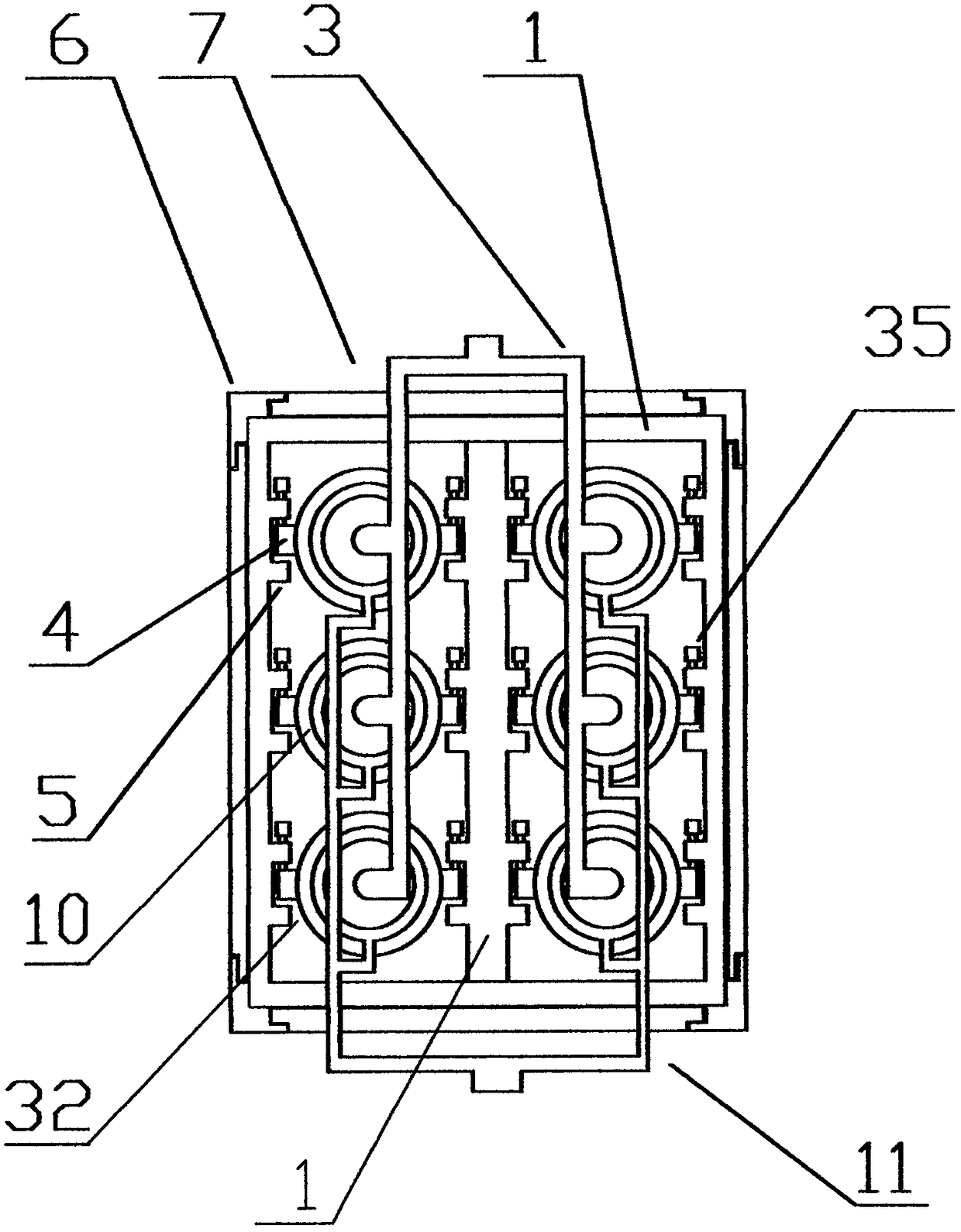

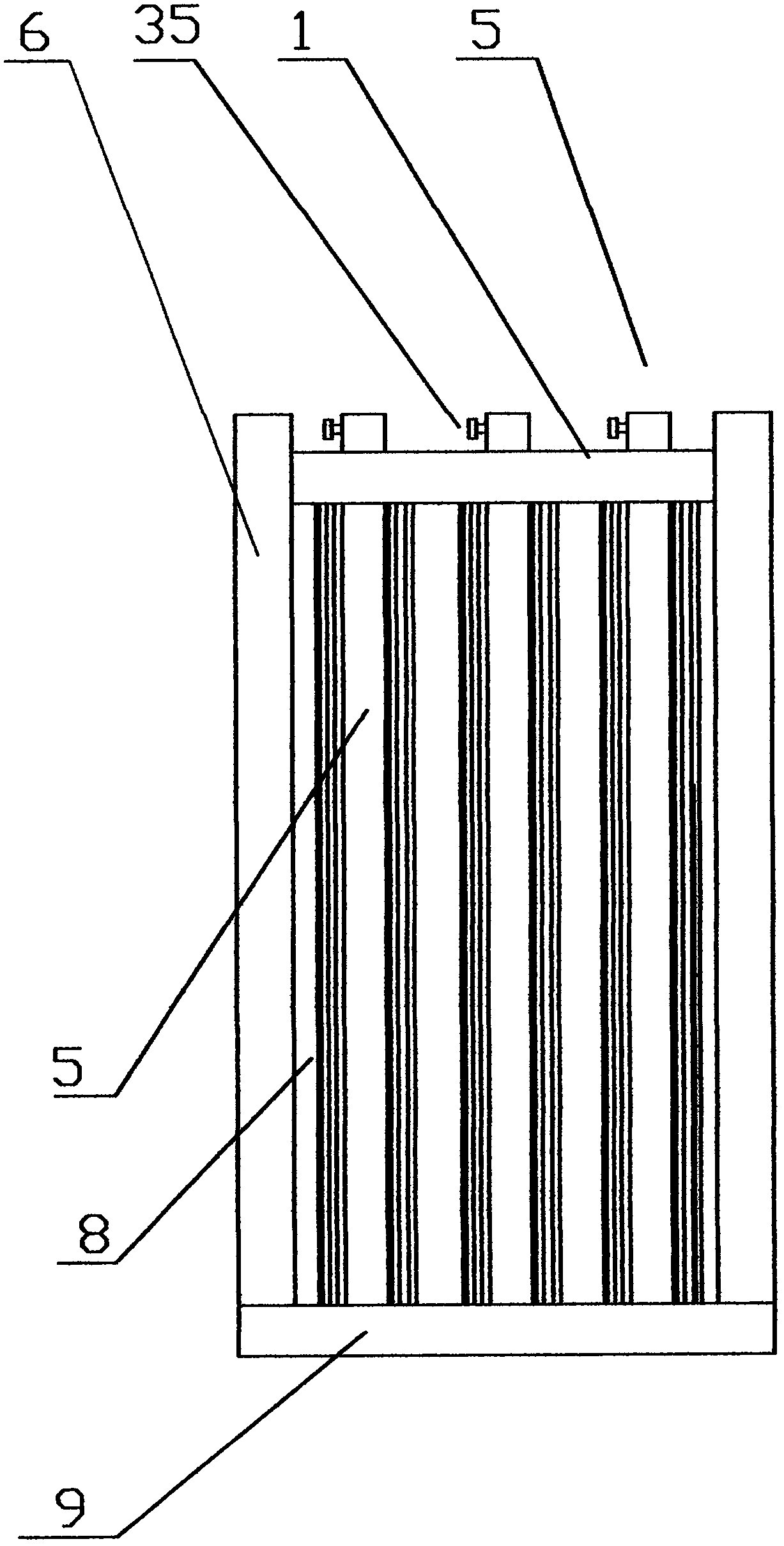

[0050] The structure and the characteristics of the self-coupling installation membrane filter equipment of the present invention are described in detail below in conjunction with accompanying drawing:

[0051] Membrane equipment for self-coupling installation, such as figure 1 , figure 2 Shown: including membrane unit, frame, slide rail system, water retaining system, lower aeration system, upper aeration system, cleaning water pump 38, cleaning agent tank 36, fan 37, product water pump 41 and valves; the membrane unit is set on the frame Inside, the lower part of the membrane unit is provided with an aeration chamber 14 or an aeration perforated pipe 29, and the lower air intake pipe 13 connected to the aeration chamber 14 or the aeration perforated pipe 29 is connected to the air outlet of the fan 37 through the air outlet pipe 21, and at the same time The lower intake pipe 13 is connected to the water inlet of the cleaning water pump 38 through the cleaning water pump i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com