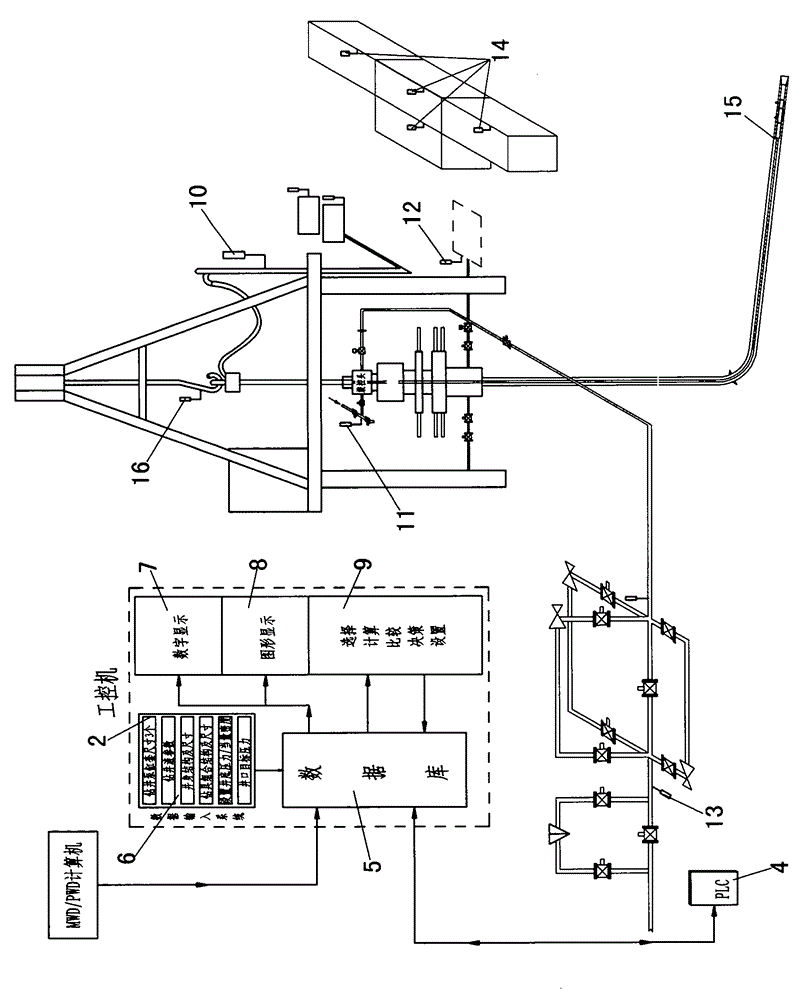

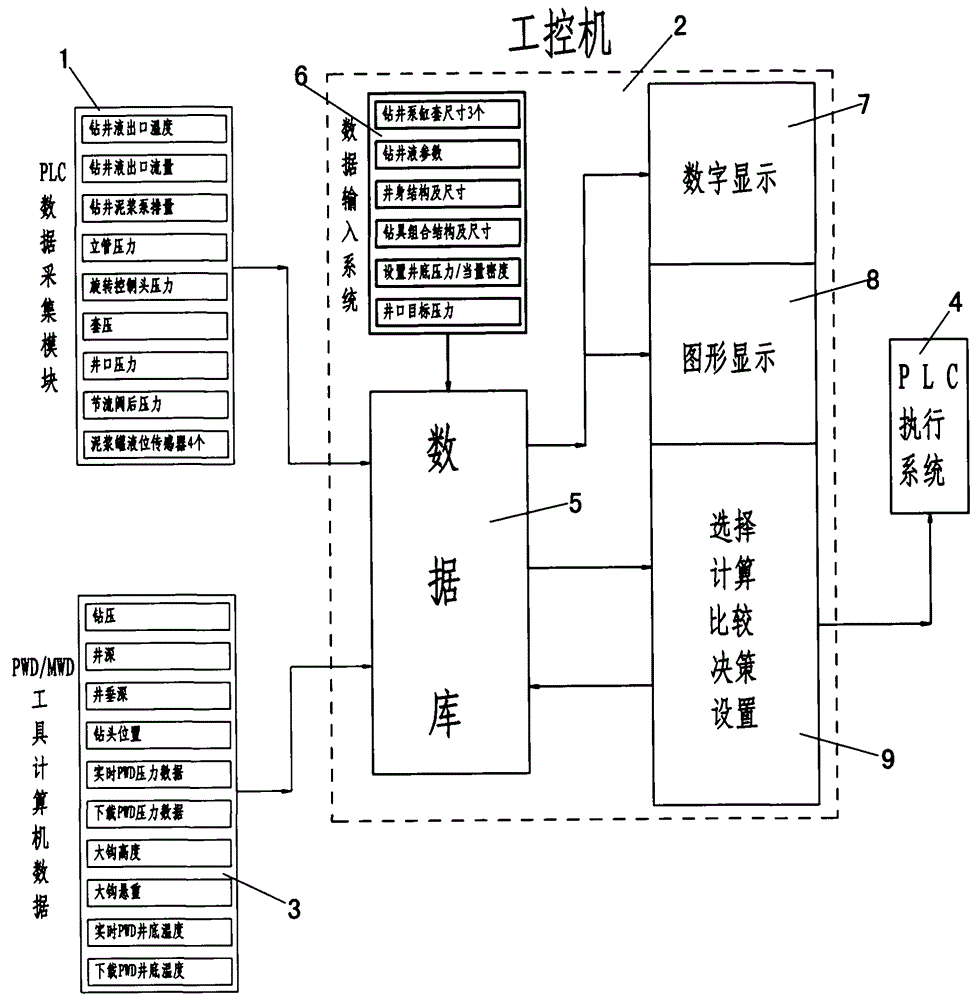

Method and device for setting target wellhead pressures in control-pressure well drilling control systems

A target pressure and control system technology, which is applied to the automatic control system of drilling, wellbore/well valve devices, drilling equipment, etc., and can solve the problems of difficult or inaccurate control of wellhead pressure, wear, and setting jumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0058] The well depth measured by the above components is 5,000 meters, the mud density is 1.2g / cm3, the wellhead pressure is 1 MPa, the pump displacement is 12 liters / second, the annular pressure consumption is 2 MPa, and the bottom hole setting pressure is 63Mpa.

[0059] The drill bit is at the bottom of the well: the wellhead setting pressure = the bottom hole setting pressure - the liquid column pressure below the drill bit - P1 + the wellhead pressure at that time;

[0060] Liquid column pressure below the drill bit=0 MPa (due to the drill bit at the bottom of the well);

[0061] P1=(Pn-n+...Pn-3+Pn-2+Pn-1) / n=(61.79+61.80+61.78+61.78+61.79) / 5=61.788MPa,

[0062] (Pn-n: must be between the liquid column pressure at the drill bit and the sum of liquid column pressure + maximum annular pressure loss + wellhead pressure, that is, between 58.8 MPa and 61.8 MPa, can be used for calculation, here: n=6, P1=61.79MPa, P2=61.80MPa, P3=61.78MPa, P4=61.78MPa, P5=69MPa, P6=61.79MPa; ...

example 2

[0067] The drill bit is measured at 3,000 meters by the above components: wellhead setting pressure = bottom hole setting pressure - liquid column pressure below the drill bit - P1 + wellhead pressure at that time;

[0068] Liquid column pressure below the drill bit = 1.2X0.0098X2000 = 23.52 MPa

[0069] P1=(Pn-n+...Pn-3+Pn-2+Pn-1) / n=(38.28+28.27+38.26+38.28+38.26) / 5=36.27MPa,

[0070] (Pn-n: must be between the liquid column pressure at the drill bit and the sum of liquid column pressure + maximum annular pressure loss + wellhead pressure, that is, between 35.28 MPa and 38.28 MPa, can be used for calculation, here: n=6, P1=38.28MPa, P2=38.27MPa, P3=38.26MPa, P4=38.28MPa, P5=45MPa, P6=38.26MPa; Note: P5=45MPa cannot participate in the calculation because it is not within the required pressure range )

[0071] At that time, the wellhead pressure was 1 MPa;

[0072] Wellhead setting pressure = 63 MPa - 23.52 MPa - 37.27 MPa + 1 = 4.21 MPa;

[0073] If the wellhead setting pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com