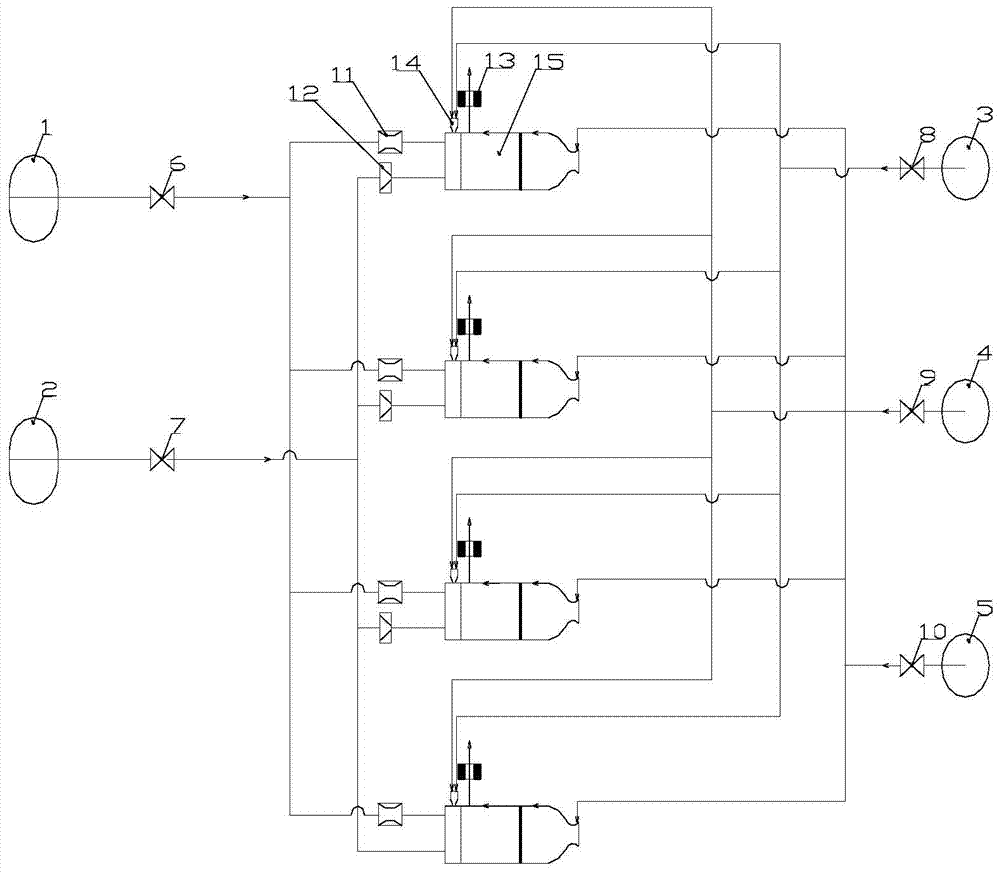

A combined multifunctional combustion device

A technology for combustion devices and combustion test pieces, which is applied in the direction of jet propulsion devices, rocket engine devices, machines/engines, etc., can solve the problems of test times, costs, and cycle requirements, so as to save development costs, realize performance comparison research, The effect of shortening the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

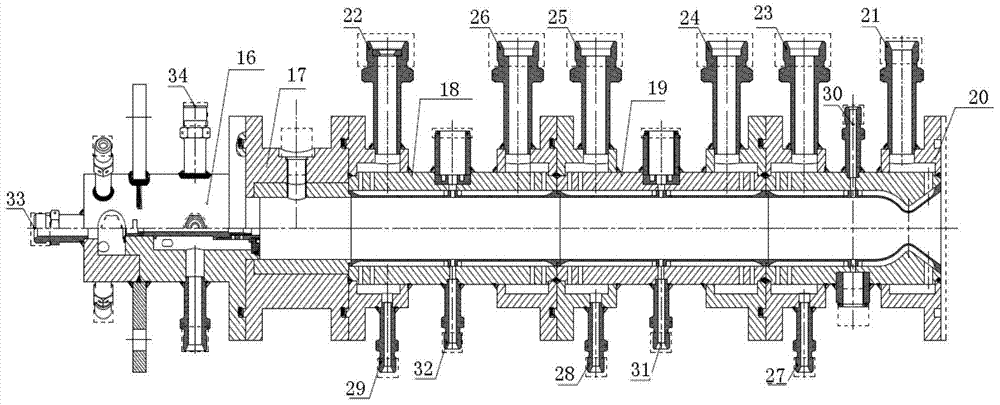

[0017] A combined multifunctional combustion device according to the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] Such as figure 2 Shown, a kind of combustion test article of the present invention, it comprises injector 16, installation section 17, 1# cylindrical section 18, 2# cylindrical section 19 and nozzle section 20 connected in sequence; An oxidant inlet 33 is provided at one end, and a fuel inlet 34 is provided on the injector 16 perpendicular to the oxidant inlet 33; a coolant outlet 22 and a 1# cylindrical section coolant inlet 26 are provided on the 1# cylindrical section 18; #Cylinder section 19 is provided with 2# cylinder section coolant inlet 24 and 2# cylinder section coolant outlet 25; nozzle section 20 is provided with coolant inlet 21 and nozzle section coolant outlet 23;

[0019] During the working process, the oxidant enters through the oxidant inlet 33; the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com