Split axial plunger pump flow distribution plate with rotatable outer sealing belt

A technology of axial plunger pump and external seal, which is applied in the direction of liquid variable capacity machinery, pumps, multi-cylinder pumps, etc., can solve the problems of cylinder overturning, unsuitable for new working conditions, and increased overturning moment, etc., to achieve Effect of avoiding leakage increase and reducing energy dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Attached below Figure 1 to Figure 6 The present invention will be further described with specific examples.

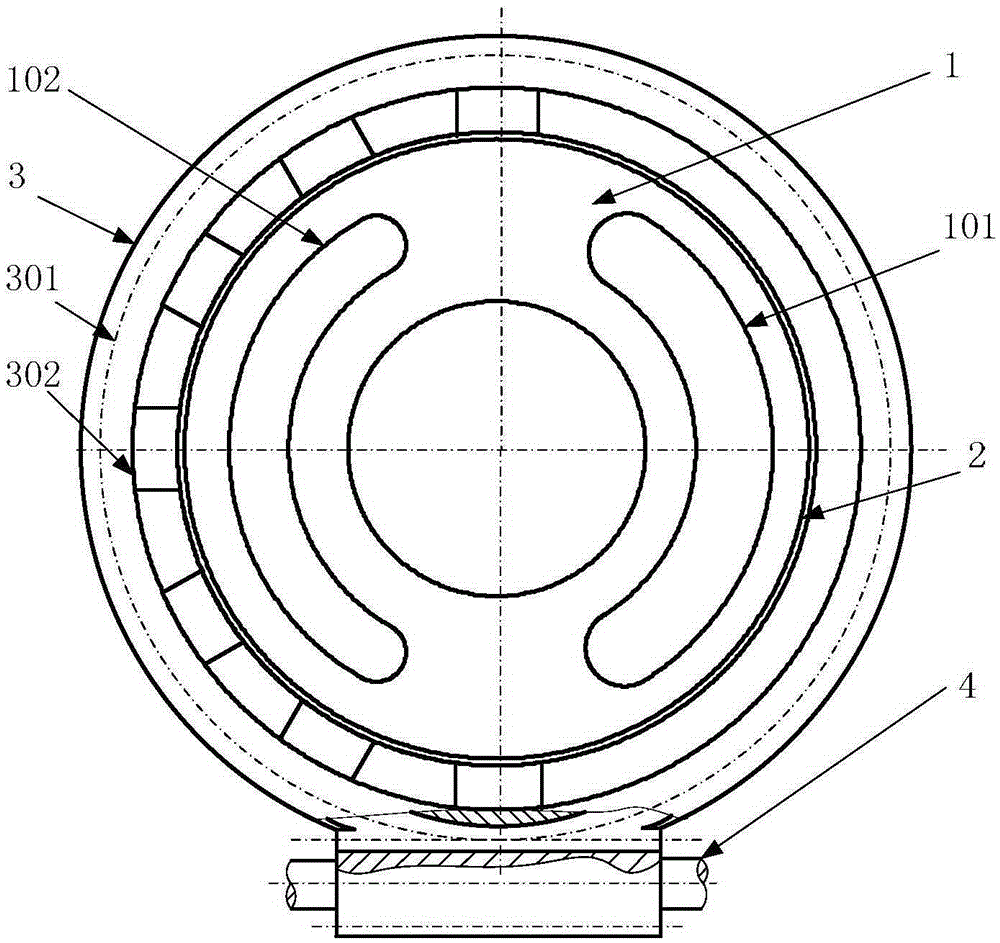

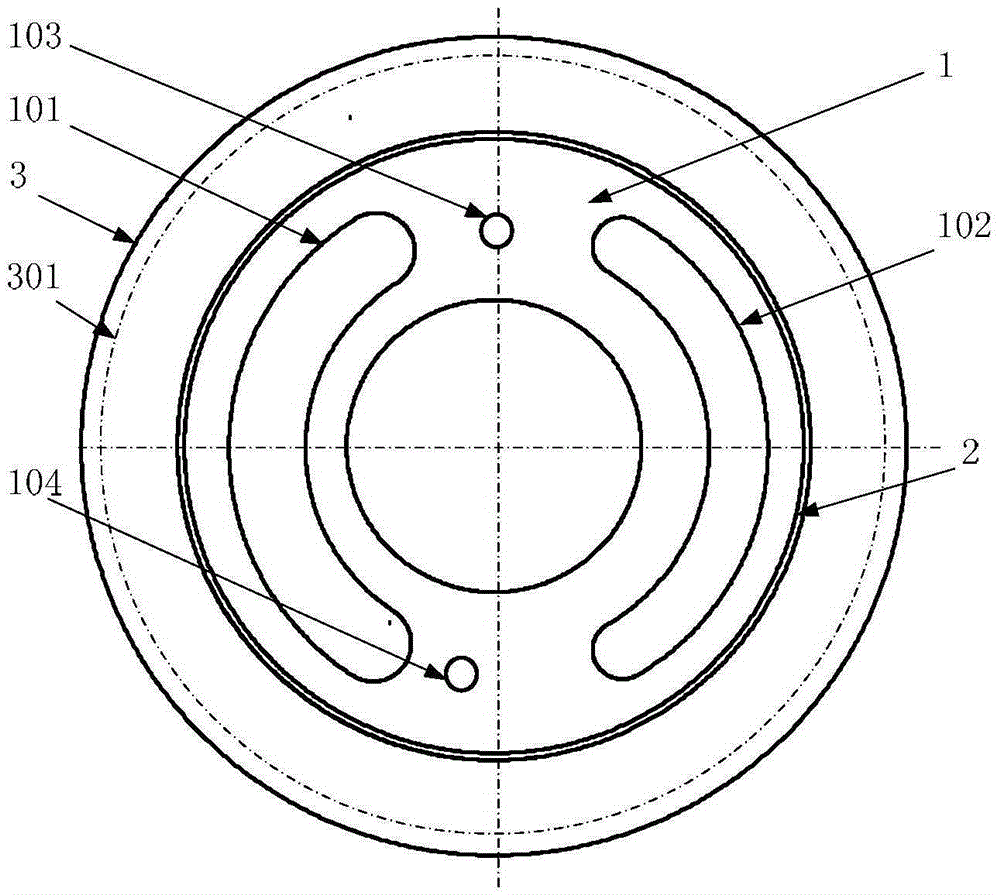

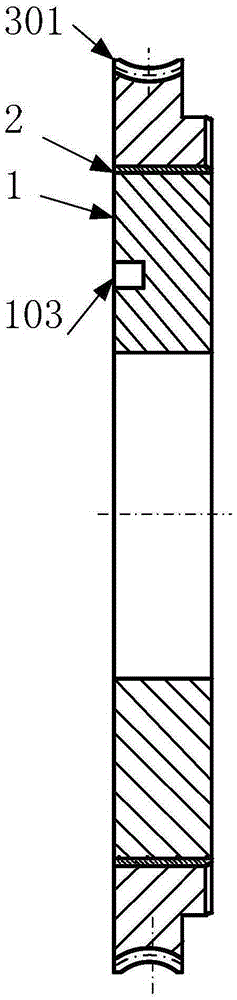

[0024] Such as figure 1 As shown, the distribution plate of the present invention is divided into an inner fixed disc 1 and a rotatable outer sealing band 3 surrounding the inner fixed disc 1 peripheral surface, and the cylindrical surface between the inner fixed disc 1 and the rotatable outer sealing band 3 passes through a sliding bearing 2 Movable connection, the two sides of the end surface of the internal fixed plate 1 are respectively provided with a low-pressure arc-shaped channel 101 connected with the pump oil suction port and a high-pressure arc-shaped channel 102 connected with the pump outlet, and the low-pressure arc-shaped channel 101 is connected with the high-pressure arc channel. The main body of the shaped through groove 102 is symmetrically located on the same annulus, such as figure 2 As shown, an upper blind hole 103 and a lower blind ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com