A Method for Analyzing the Composition of Spinning Bath Using On-line Automatic Analyzing Device

An automatic analysis device and spinning bath technology, which is applied in the direction of chemical analysis, analysis materials, instruments, etc. by titration, can solve the problems of deviation of test results, high work intensity, and complicated process, so as to improve measurement accuracy and improve Work efficiency and safety factor, the effect of reducing labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the accompanying drawings and embodiments.

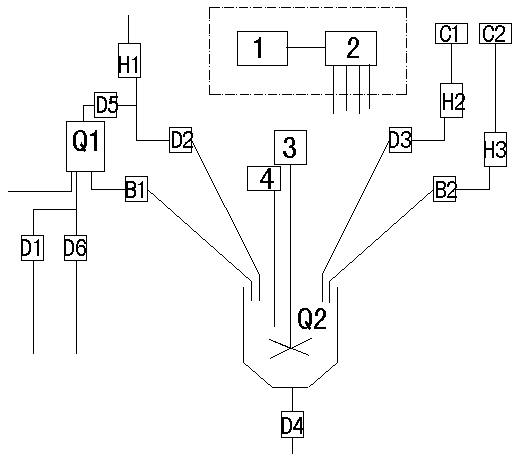

[0032] see attached figure 1 , the online automatic analysis device of the spinning bath composition disclosed by the present invention includes a man-machine operation unit for online recording, display and parameter adjustment; a control unit for controlling the solenoid valve, metering pump and concentration calculation; Sampling unit for real-time sampling in spinning bath and addition of standard reagents; analysis unit for analyzing pH of liquid; automatic cleaning unit for solving pipeline blockage caused by crystallization of spinning bath and affecting measurement results. The main components of each unit are as follows : 1- man-machine interface, 2- electrical control unit, 3- stirrer, 4- PH meter, D1- solenoid valve, D2- solenoid valve, D3- solenoid valve, D4- solenoid valve, D5- solenoid valve, D6 - Solenoid valve, H1-buffer cup, H2-buffer cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com