Automatic shielding test device and test flow line thereof

A technology of testing devices and shielding boxes, which is applied in the direction of shielding devices, measuring device shells, electromagnetic field characteristics, etc., can solve the problems of low equipment utilization, low testing efficiency, and high equipment costs, and achieve high testing efficiency, fast action, and control simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to illustrate the technical solution of the present invention more clearly, the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. Obviously, the following descriptions are only some embodiments of the present invention. In other words, other embodiments can also be obtained according to these embodiments without paying creative efforts.

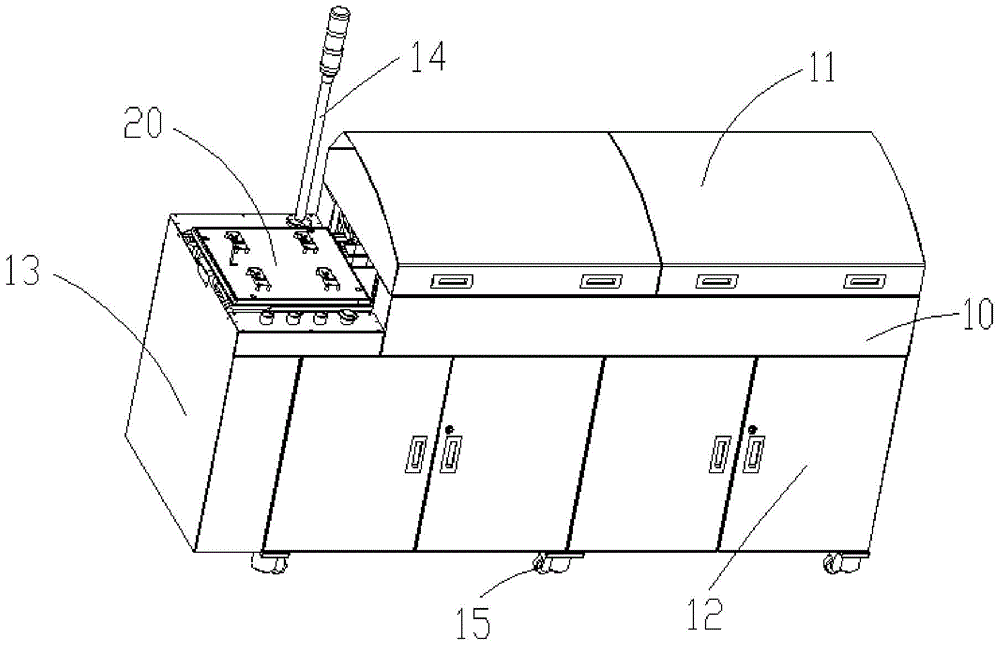

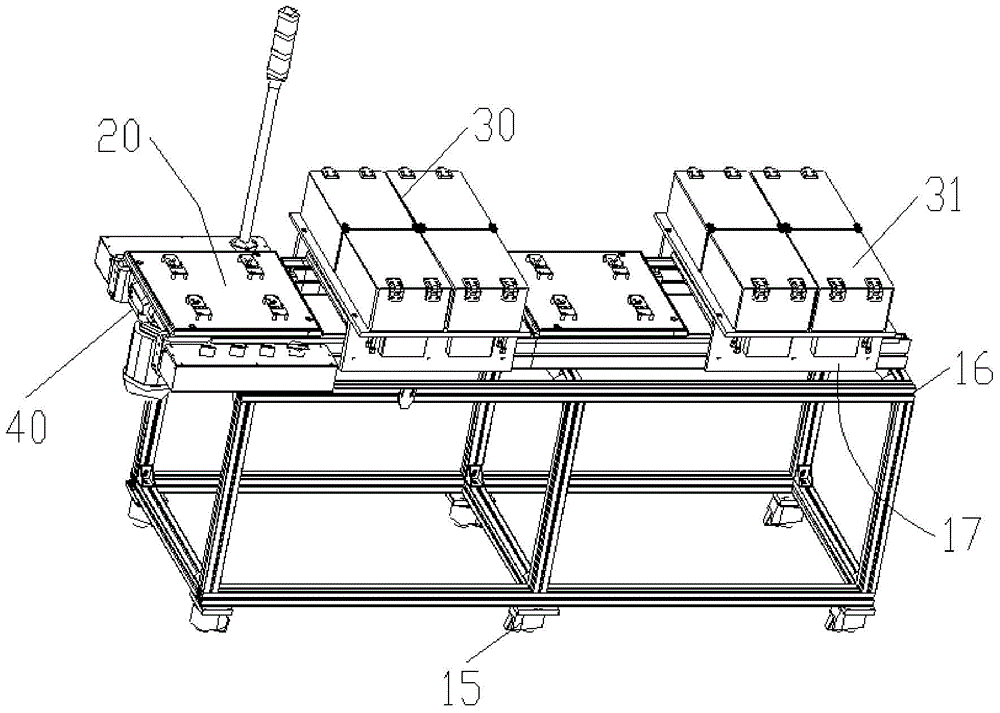

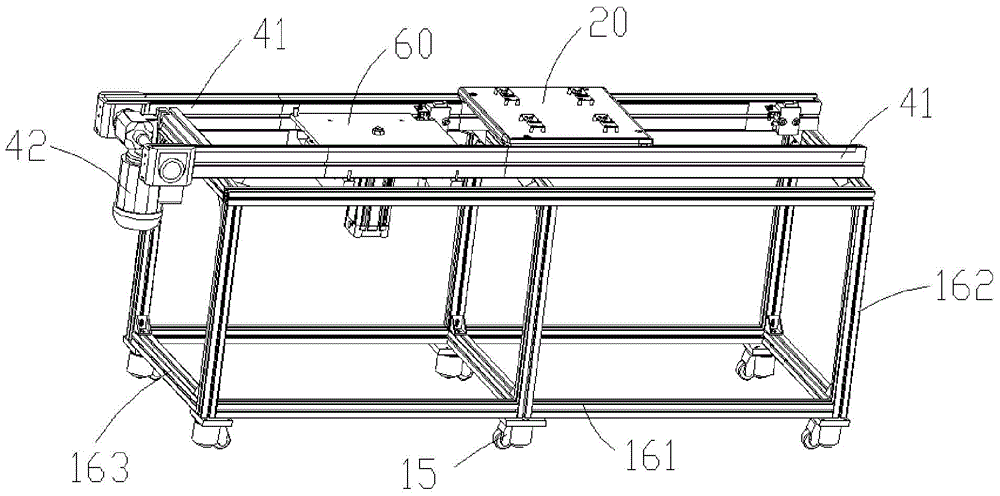

[0048] refer to figure 1 , figure 2 , an on-line automatic shielding test device, including a cabinet 10, and at least one shielding test unit 30 installed in the cabinet 10, a first rail conveyor belt 40, a tray 20, a jacking mechanism 60 and a test control mechanism, the shielding test unit 30. The first track-type conveyor belt 40 and the jacking mechanism 60 are respectively electrically connected to the test control mechanism and coordinate operations under the control of the test control mechanism;

[0049] The shielding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com