A Miniaturized Stripline Power Amplifying Module

A technology of power amplification module and strip line, which is applied in the structural connection of printed circuits, printed circuit components, electrical components, etc., can solve the problems of cumbersome process steps, high manufacturing costs, unfavorable debugging, etc., and achieve superior quality and performance, The effect of simplifying the production process and saving the time required to make the copper skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

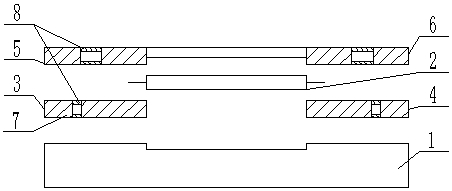

[0024] like figure 1 , Figure 5 and Image 6 As shown, a miniaturized stripline power amplification module, which includes a substrate 1 provided with a groove, a power transistor 2 installed in the groove, a printed board A3, a printed board B4, a printed board C5, a printed board Make board D6, feeder circuit A and feeder circuit B.

[0025] The printed board A3 and the printed board B4 are installed on the substrate 1, the printed board C5 cover is pressed on the printed board A3 and forms the input matching circuit of the power amplifier with the printed board A3; the printed board D6 cover is pressed on the printed board A3 The output matching circuit of the power amplifier is formed on the board B4 and the printed board B4; the input matching circuit is electrically connected to the input end of the power transistor 2, and the output matching circuit is electrically connected to the output end of the power transistor 2.

[0026] The feeding circuit A is arranged on t...

specific Embodiment approach 2

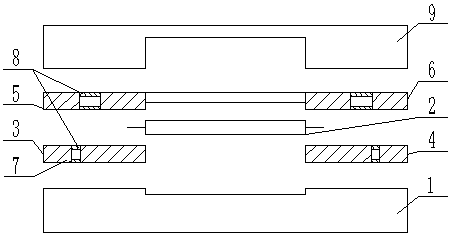

[0029] The difference between this specific embodiment and specific embodiment 1 is that: the printed board C5 and the printed board D6 are also provided with a metal cover 9, and the metal cover 9 is used to compress the upper and lower printed boards, Ensure close contact between upper and lower printed boards. The metal cover plate 9 has a hole at the DC blocking capacitor for installing the DC blocking capacitor. The specific structure is as figure 2 , Figure 5 and Image 6 shown.

specific Embodiment approach 3

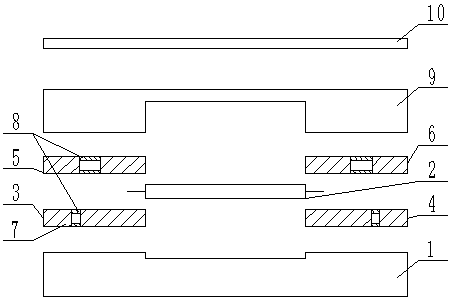

[0030] The difference between this specific embodiment and specific embodiment 2 is that the printed board C5 and the printed board D6 are manufactured separately, and the printed board E10, the feed circuit A and the feed circuit A are also provided on the metal cover 9 The circuits B are all arranged on the printed board E10, the feed circuit A is electrically connected to the input matching circuit, and the feed circuit B is electrically connected to the output matching circuit. The specific structure is as image 3 , Figure 5 and Figure 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com