Tea peduncle, stem and leaf separation device

A technology for separating stems and leaves and tea stems, which is applied in the field of machinery and equipment, can solve the problems of reduced workers, sharply reduced output, and no use for them, and achieves the effects of improving efficiency and quality, occupying less space, and being easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

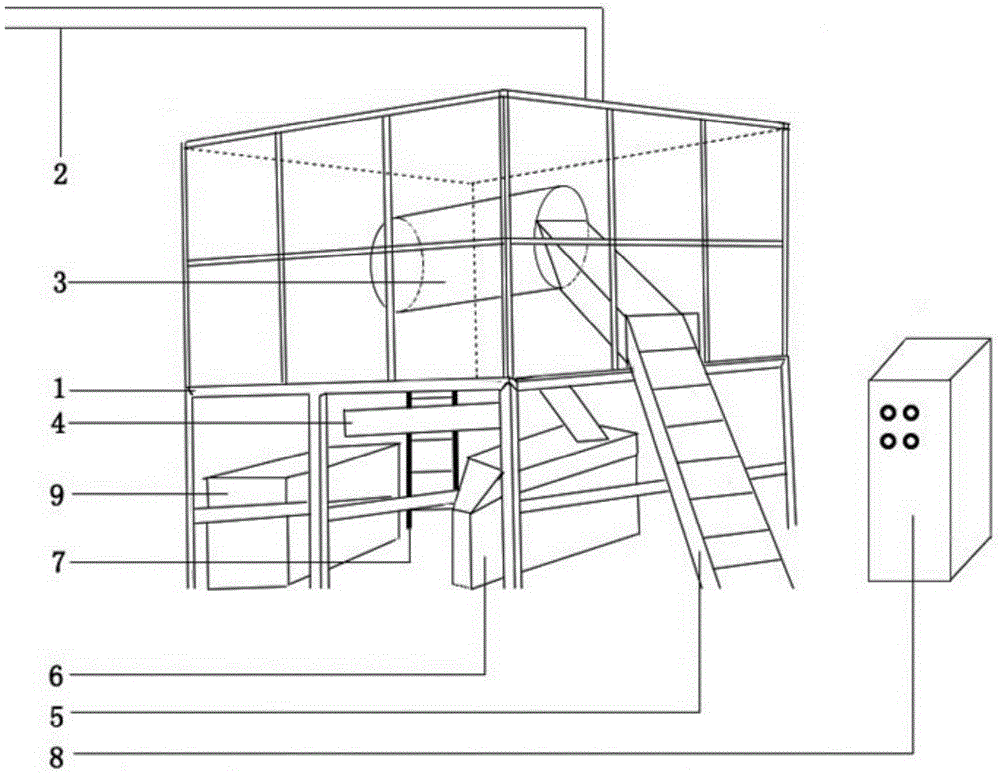

[0019] See figure 1 , a kind of tea stem leaf separation device according to the present invention comprises a frame 1, a dust removal device 2 is arranged above the frame 1, a round sieve 9 is arranged at the bottom of the frame 1, and one side of the round sieve 9 is A vibrating screening machine 6 is provided, a horizontal conveyor 4 is arranged above the circular screening machine 9, a shredder 3 is arranged above the flat conveyor 4, and an inclined conveyor 5 is arranged on one side of the shredder 3 , a control cabinet 8 is provided on one side of the frame 1; the frame 1 includes an upper sealed box and 4 lower columns, the dust removal device 2 is arranged above the upper sealed box, and the shredder 3 is arranged on the sealed box In the box, the flat conveyor 4, the circular screen machine 9 and the vibratory screening machine 6 are all located below the upper sealed box and between the four lower columns; the front wall of the frame 1 is provided with a transfer po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com