A kind of magnetic resonance variation spectrum material and its preparation method

A magnetic resonance and spectroscopy technology, applied in the direction of magnets, magnetic objects, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing a magnetic resonance variation spectrum material, comprising the following steps:

[0031] 1) Sample loading: put iron-platinum powder in a heat-resistant crucible, put it in an induction compound heating powder making device, fill it with argon after vacuuming, and keep the argon pressure at 1KPa;

[0032] In this step, the induction compound heating powder making device is changed to a self-adjusting laser-induction compound heating powder making device. The induction compound heating powder making device includes a vacuum reactor, a laser generator, an ultrasonic generator, a heat-resistant crucible, and a nozzle. ; Its radiation source has been improved and added an ultrasonic radiation source; the heat-resistant crucible is preferably Al 2 o 3 heat-resistant crucible;

[0033] 2) Melting: start the high-frequency induction power supply heating, the input power is 10KW, and heat until the iron and platinum powder melt;...

Embodiment 1

[0039] A method for preparing a magnetic resonance variation spectrum material, comprising the steps of:

[0040] 1) Sample loading: put iron-platinum powder in a heat-resistant crucible, put it in an induction compound heating powder making device, fill it with argon after vacuuming, and keep the argon pressure at 1KPa;

[0041] 2) Melting: start the high-frequency induction power supply heating, the input power is 10KW, and heat until the iron and platinum powder melt;

[0042] 3) Irradiation: Introduce ultrasonic-laser composite source, ultrasonic 25Khz, laser power 2900W, spot diameter 5mm, adjust the distance between the argon shielding gas nozzle and the metal liquid surface to 20mm, generate plasma arc, and receive ultrasonic irradiation and laser The irradiated iron-platinum fume is cooled on the cooling wall to obtain black powder, which is the magnetic resonance variation spectrum material.

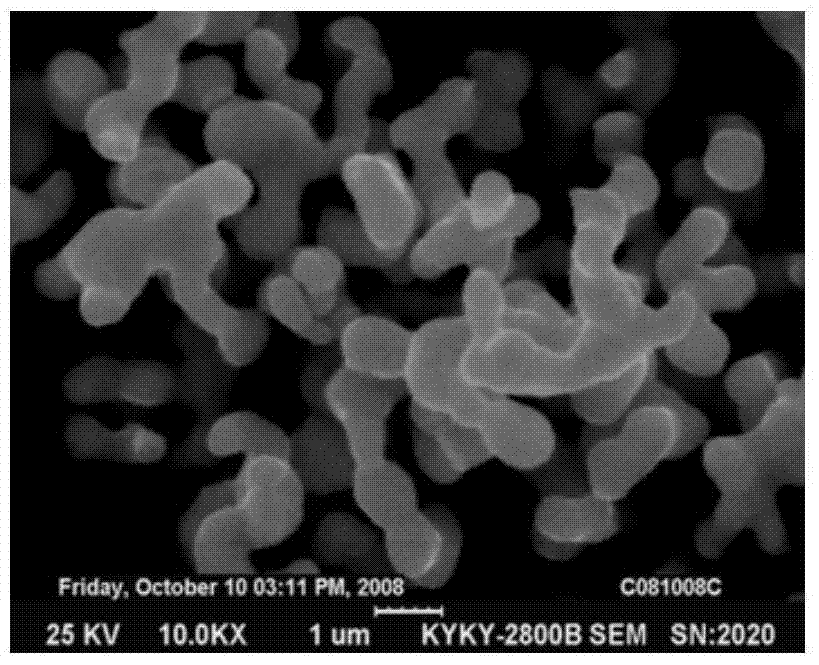

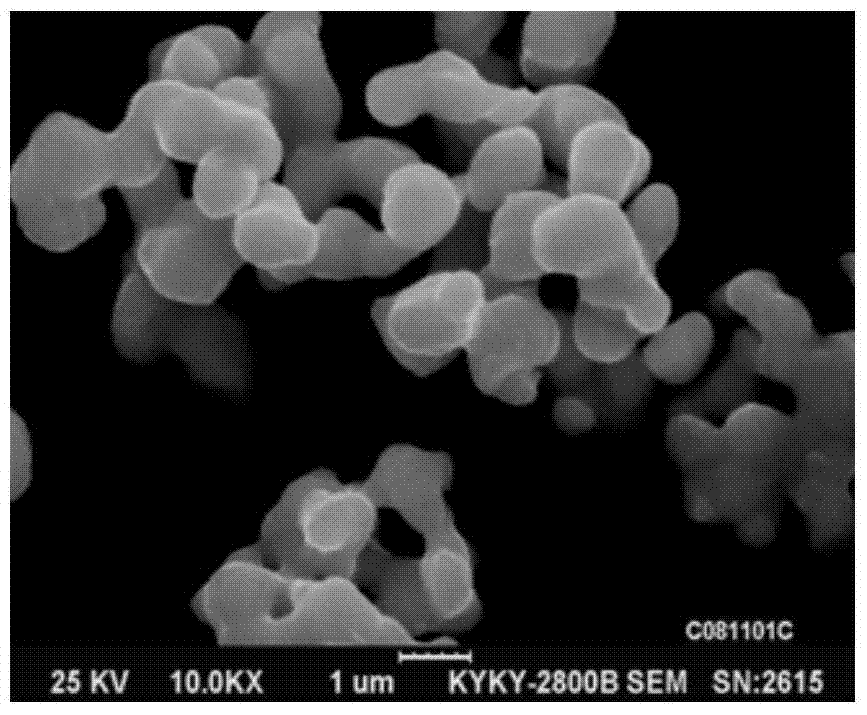

[0043] The magnetic resonance variation spectrum material that embodiment ...

Embodiment 2

[0045] A method for preparing a magnetic resonance variation spectrum material, comprising the steps of:

[0046] 1) Sample loading: put iron-platinum powder in a heat-resistant crucible, put it in an induction compound heating powder making device, fill it with argon after vacuuming, and keep the argon pressure at 1KPa;

[0047] 2) Melting: start the high-frequency induction power supply heating, the input power is 10KW, and heat until the iron and platinum powder melt;

[0048] 3) Irradiation: Introduce an ultrasonic source, ultrasonic 25Khz, adjust the distance between the argon shielding gas nozzle and the metal liquid surface to 20mm, generate a plasma arc, and cool the iron-platinum fume irradiated by ultrasonic and laser on the cooling wall , to obtain black powder, that is, magnetic resonance variation spectrum material.

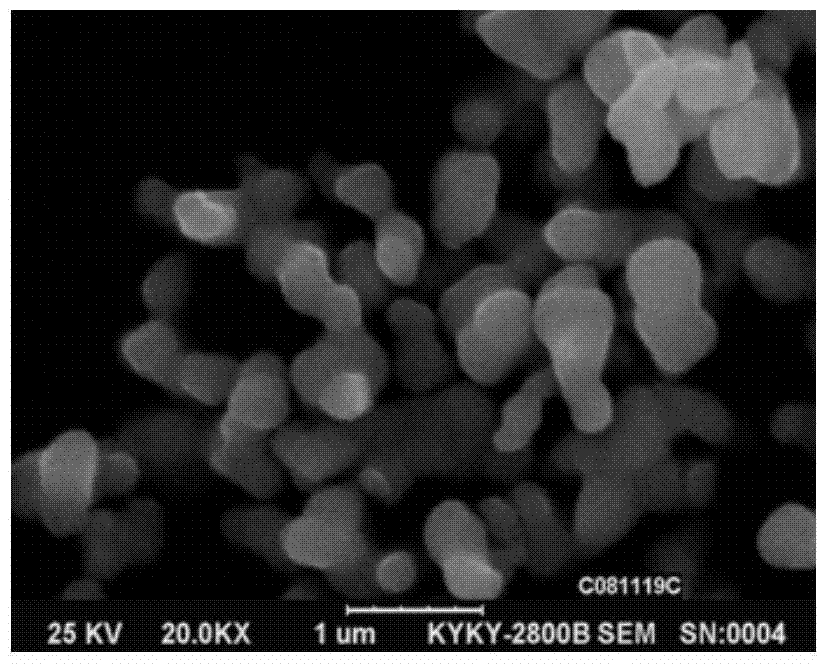

[0049] The magnetic resonance variation spectrum material that embodiment 2 obtains is analyzed its appearance through JSM-35C type transmission el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com