A butt welding positioning fixture and its application method

A positioning fixture and butt welding technology, applied in the field of welding, can solve the problems of difficult to take out the hoop of the parts, time-consuming and laborious, deformation of the parts, etc., and achieve the effect of easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

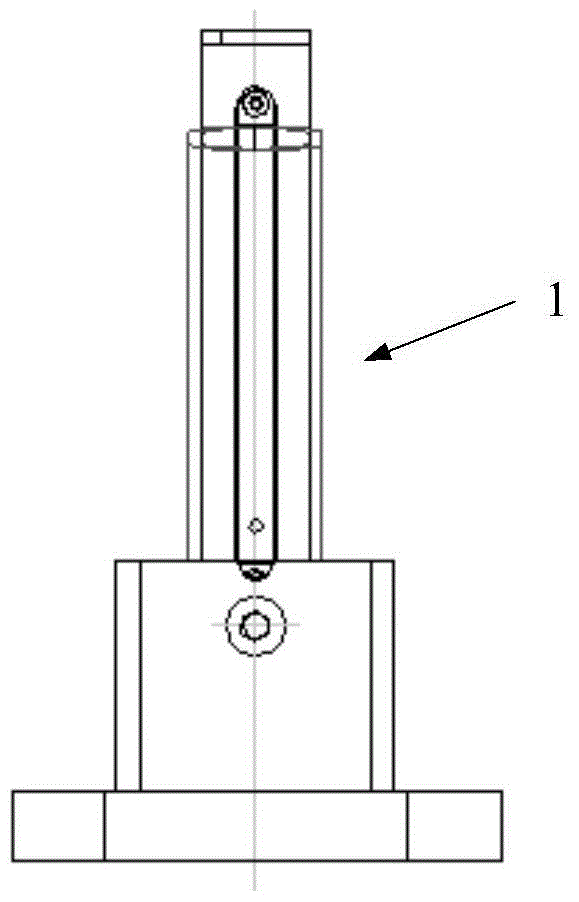

[0044] The present invention is a two-bow type thin-walled butt welding positioning fixture designed by utilizing the method of split combination and the advantages of paired cone blocks used together, such as Figure 2 to Figure 6 As shown, the welding positioning fixture includes three parts: a positioning assembly 1 , a pressing assembly 2 and a discharge block 3 .

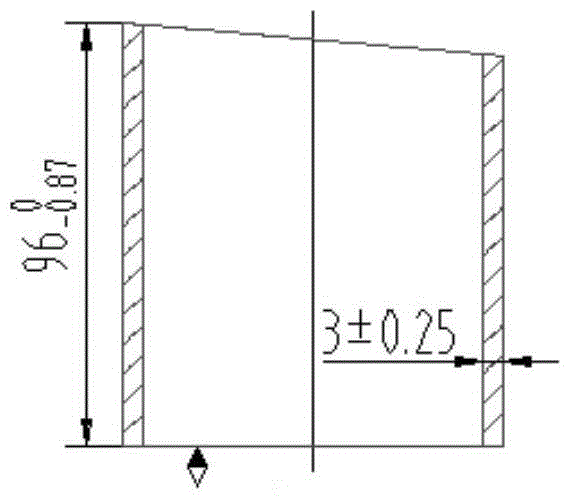

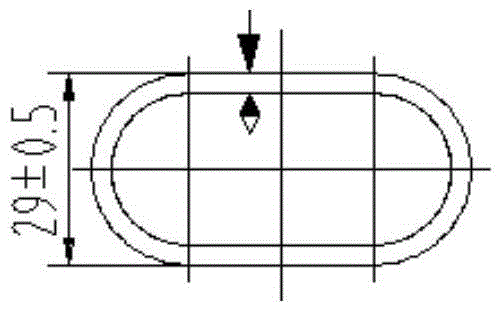

[0045] see Figure 7 , the positioning assembly 1 is composed of a positioning seat 1a, a screw 1b and a positioning assembly 1c for socketing parts. The internal dimensions of the parts match the external dimensions of the positioning assembly 1c. In the present invention, the parts are butt welded with two bow-shaped thin-walled parts The guide post 5 is taken as an example, the upper end of the positioning seat 1a faces the guide post 5 to perform end face positioning, that is, when the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com