A barrel input positioning device

A positioning device and cylinder technology, applied in auxiliary devices, applications, auxiliary welding equipment, etc., can solve problems such as low efficiency and inaccurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

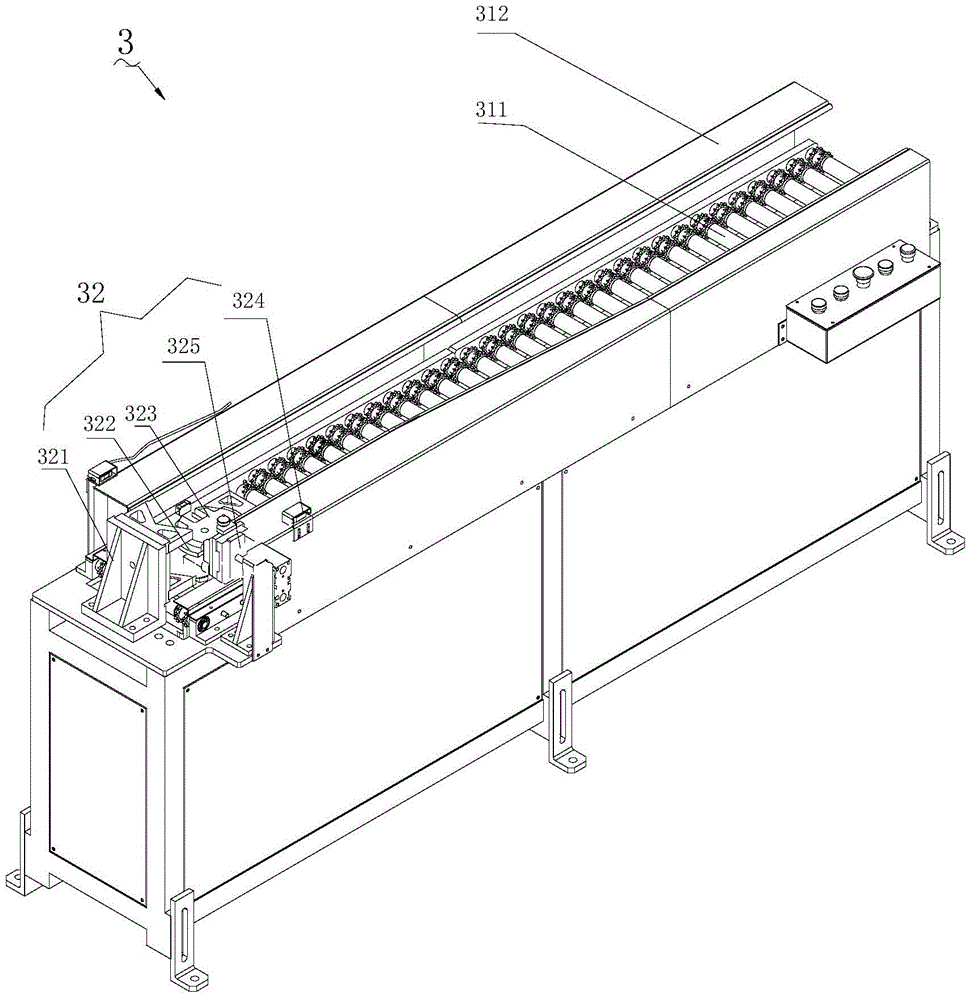

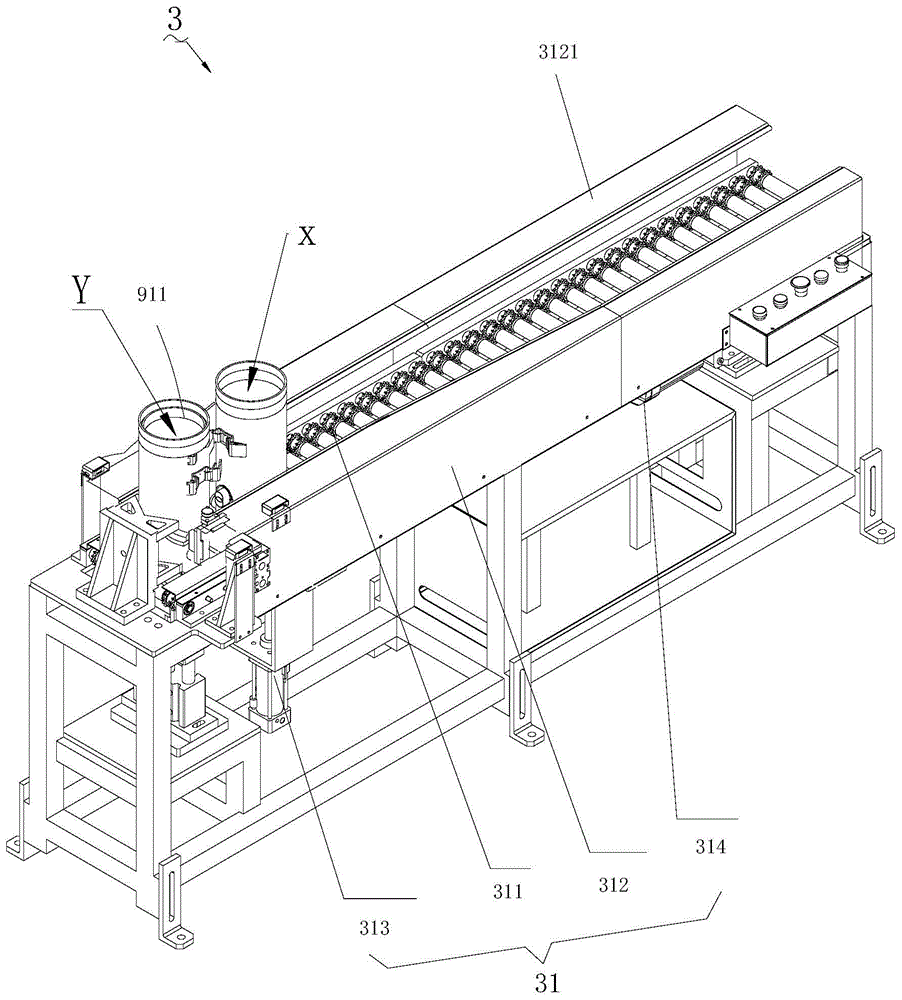

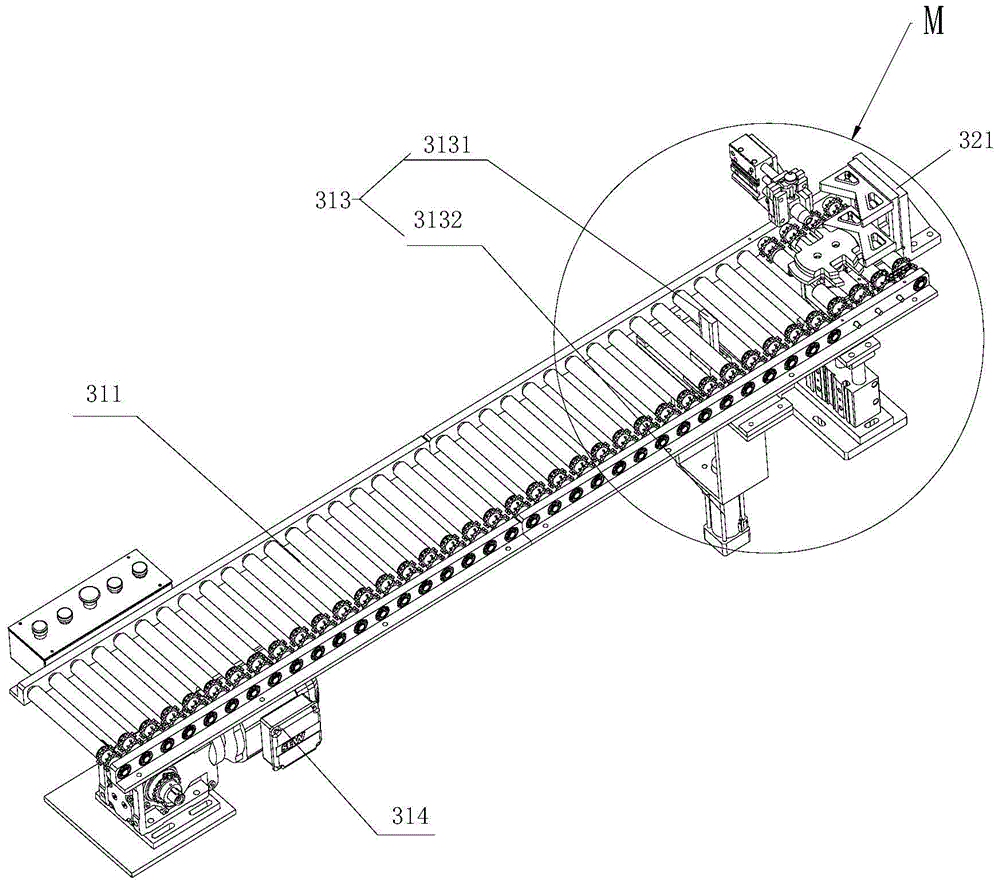

[0035] like Figure 1 to Figure 5 As shown, a barrel input positioning device 3, a barrel input positioning device 3, is used to transport the barrel 911 and position the barrel 911. The barrel is divided into a welded suction pipe and an unwelded suction pipe Two states. The cylindrical body of the welded suction pipe is positioned with the outer edge of the suction pipe; the cylindrical body of the unwelded suction pipe is positioned with the hole at the suction pipe to be welded, and the hole is adapted to the positioning guide post 3251 to be described below. The cylinder input positioning device 3 includes a cylinder input mechanism 31 with an input track 311 and a cylinder posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com